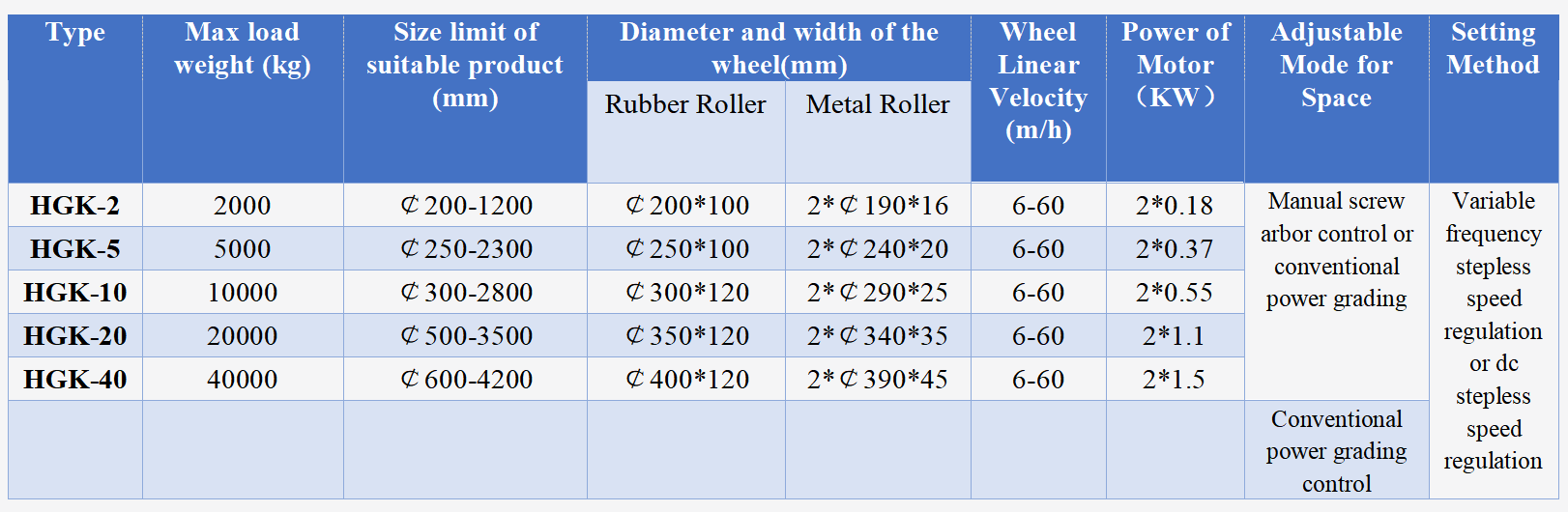

Lead Screw Welding Rotator

Welding rotators consist of a lead screw welding rotator and bolt screw welding rotator. Lead screw welding rotator is one of the invention patents made by Fengwei Machinery, mainly used to meet client’s request of welding small cylinders and avoid damaging the motor, reducer, and electric control box. It is widely used in the industries of fabricating pipelines with small diameters such as signal power poles.

-

Model

Adjustable\Self-aligned\Fit up\Growing line

-

Loading Capacity (kg)

1,000 - 3,000,000 above

Lead screw welding rotator includes motors, reducers, an electric control box, screw adjusting mechanisms, screw nut blocks, rollers, roller bed, and a base. Where in the base is a box; the screw adjusting mechanism includes a screw rod and a control hand wheel; the control handwheel is installed at one end of the screw rod and located on the side of lead screw welding rotator; the base is settled with a sliding rail for the roller bed to move along; the roller bed is installed on the slide rail and can move horizontally on the base; the roller is fixed on the roller bed through a rotating shaft; the nut block is fixed to the bottom of the roller seat; the nut block It is provided with a thread matched with the screw, the screw is matched with the nut block and installed in the box of the base; the output shaft of the motor is connected with the reducer; wherein; the motor, the reducer, and the electric control box are installed inside the box body of the base for safety.

Welding rotators are widely used for assisting in rotating cylindrical workpieces, welding longitudinal and circumferential seam of pressure vessels, circumferential welding of disc-shaped working ends and shells, circumferential welding of pipes, and flanges, and butt welding of large-diameter pipelines. Welding rotators are also applied for the assembly, cutting, heating, polishing, rubber lining, and painting of tanks, boxes, pipelines, pressure vessels, etc.

With vigorous investment in the 5G industry the worldwide, power pole industry is developing rapidly, and there is a large demand for signal power poles. The power signal pole has a small diameter but a long length which is not easy to hoist. The conventional welding rotator can only meet the 250 mm minimum diameter of the cylinder. Therefore, Fengwei Machinery was devoted to research and develop a lead screw welding rotator, which effectively met the power pole industry’s request.

A conventional welding rotator normally mounts the motor and the reducer on the side of the roller bed. During the operation, the motor, reducer, and electric control box are often damaged due to improper operation, causing economic losses to users and reducing production efficiency. lead screw welding rotator is designed to install the motor, the reducer, and the electric control box underneath, so as to reduce the risk of damage.

Welding Rotator

The whole welding rotator has strong rigidity and stability, beautiful appearance, reliable performance, simple maintenance and long service life. Learn more about the details and types of welding rotators.

-

Self-adjusting Welding rotator|Safety Operation Guide

Fengwei has 20 years of experience in the design and development of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world.

self-adjusting welding rotator -

welding rotator|US hot sale

Fengwei is a professional in the manufacture and research and development of welding rotators. Various types of welding rotators have been recognized in the welding application fields of various large-scale equipment in the United States.

welding rotators -

Welding Roller | Welding rotator manufacturer

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators.

Welding rollers -

The Best Quality Self Adjusting Welding Rotator From China

Self-adjusting welding rotator is a kind of equipment used with a welding manipulator, which is used to support or drive rotation when welding straight seams and circumferential seams of pressure vessels and large-diameter pipes.

Self-adjusting welding rotator -

Improve Weld Quality|Welding Rotator

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding.

welding rotator -

Adjustable Welding Rotator - Explosion-Proof & Anti-Channeling

The adjustable welding rotator consists of a driving frame and a driven frame as a set and generally does not need to make an installation foundation.

welding rotator