Pipe Welding Positioner

A pipe welding positioner is a mechanical component of the system that holds and rotates a workpiece so that a welder can paint at the correct angle and on a level surface. Even while carrying a lot of weight, it can spin quickly. The welder may robotically trade its function to an orientation that allows the complete extraction into weld joints, from a more relaxed position, since the device holds it securely in a flat function.

-

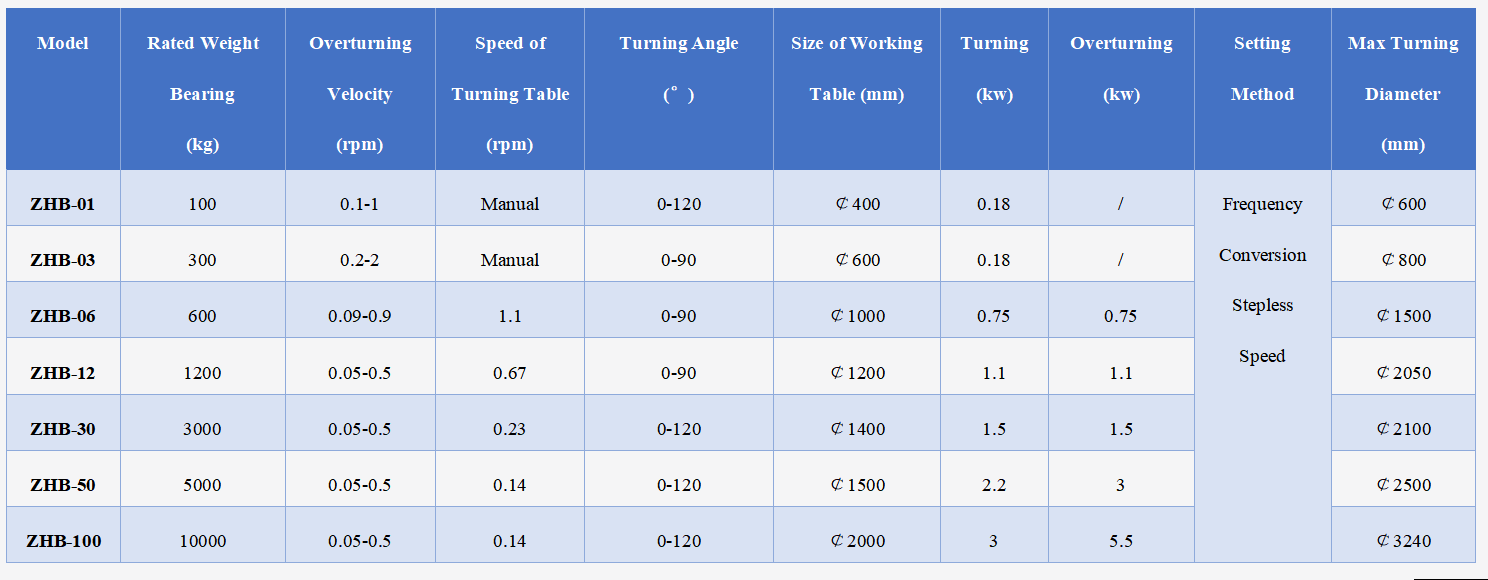

Loading Capacity (kg)

20 - 20,000 above

-

Rotation Speed (rpm)

0.2-2 (per request)

-

Application

Welding, Grinding, Sputter

A pipe welding positioner is a mechanical component of the system that holds and rotates a workpiece so that a welder can paint at the correct angle and on a level surface. Even while carrying a lot of weight, it can spin quickly. The welder may robotically trade its function to an orientation that allows the complete extraction into weld joints, from a more relaxed position, since the device holds it securely in a flat function. Sub assemblies or components can be provided without an interruption in the process and without the need for complicated welding torch maintenance procedures. The main purpose of a pipe welding positioner is to guarantee that the workpiece is always in the best welding position.

Beneficial Features Of pipe welding positioners

pipe welding positioners: The multitude of helpful capabilities that Fengwei weld placement devices offer has made them popular in most sectors. The following are some of the heavy greatest duty's striking capabilities.

Expanded Productivity: Employee motion for wearing out the welding process is significantly reduced with this device. As a result, even with the employment of this weld placement device, no fatigue is caused. This allows for an increase in overall productivity.

Reduced Exertions Cost: pipe welding positioners aid in improving production while requiring less effort. This method allows for single-exceeded activity manipulation and welding, which helps to save labour costs.

Decreased Defects & Superior Great: Because this gadget is so simple to use, even lead labour can use it effectively. This improves weld quality while lowering the likelihood of flaws and rejection.

Extremely Good Adaptability: These weld placement devices are very adaptable to both guided and automated welding.

To Be Had In Distinct Capacities: Weld positioning devices are available in a variety of capacities, including 500 kilogrammes, 800 pounds, and 1200 pounds.

Incredible Weld: The overhead or vertical runs are avoided when using such desktop weld positioners. This makes it easier to achieve excellent weld uniformity.

Smooth Positioning: Weld Positioners can readily put in typically shaped or difficult-to-form tasks so that down hand welding may be done.

Wonderful Flexibility: As a result of pipe welding positioners' job principle, you receive the maximum amount of flexibility.

pipe welding positioners have the same operating principle regardless of the size of the assignment. Using clamps or bolts, the operator secures the base product or workpiece to the pipe welding positioner. The welder may robotically trade its function to an orientation that allows the complete extraction into weld joints, from a more relaxed position, since the device holds it securely in a flat function. Sub assemblies or components can be provided without an interruption in the process and without the need for complicated welding torch maintenance procedures.

Varieties Of pipe welding positioners

FENGWEI offers a variety of welding automation equipment, such as pipe welding positioners, for sale, rental, and hiring. Weld positioning devices are divided into four types:

Manual: To carry the weld inside the specified course at the correct velocity, these machines can be controlled using manual hand cranks or shift paddles.

Semi-Automatic: A pipe welding positioner that works in conjunction with other equipment to boost production. Accessories such as a torch stand, for example, can be attached to the positioner to allow welding to be done with a stationary torch.

Computerized: Weld Positioners can employ robotics for applications that need greater weld precision and reproducibility. Automated welding stations are ideal for supplying large quantities of weldments. Well-known pipe welding positioners are devices that allow for complete 360-degree rotation of workpieces for welding.

Rotary pipe welding positioners: Operators utilise rotary weld positioners for precise welding packages on circular devices. You may adjust the right velocity using a variable speed management field and an optionally accessible variable-pace pedal.

The Right Use Of A pipe welding positioner

When utilising a welding turntable, whether it's a ground or benchtop weld positioner, safety must always be the main priority. The welding workstation must be secured to a firm floor in order to maintain its horizontal position. Nice tack welds give some pressure, oppose weld tensions, and prevent the rims of the joints from being moved in addition to gripping the workpiece. To an adjustable clamp, the fixed torch must remain constant.

To avoid damaging the electrical components during the welding process, the weld positioning device must be linked to a floor modern-day. It is critical to use the pipe welding positioners according to the manufacturer's instructions. Before beginning welding operations, review spec sheets and manuals regarding the size, weight, and velocity requirements, as well as which activities they can handle.

Need For pipe welding positioners And Their Usage In Industries

pipe welding positioners allow a welder to stay in one position while painting on a level surface. This reduces employee fatigue and boosts production by eliminating the need for the welder to continually travel across the workpiece to finish the weld.

Because there are no overhead or vertical runs, this kind of workpiece presentation also tends to ensure consistently beautiful welds.

In various sectors, “pipe welding positioners” are used to shorten the route necessary to reach and get access to components while also reducing the number of times a part must be physically moved.

Because it rotates the workpiece at a controlled rate and speed to maintain a non-stop, penetrative weld, a "pipe welding positioner" addresses numerous weld issues.

FENGWEI pipe welding positioners may be used for circular welding, strip cladding, down hand role welding, and more. They can also be utilised to lay the work up for easy access to difficult assemblies.

With the use of a weld positioners and your website, you may significantly improve the quality of your welds. The above-mentioned weld holders are among the best on the market and are certain to serve you for many years to come. Keep an eye out for features like rotation in line with the minute and ease of operation, since these contribute significantly to the overall unity of hose weld positioners.

Now that you've learned everything there is to know about the primary products, it's up to you to pick the one that best matches your welding needs.

Welding Positioner

-

Fengwei new welding positioner|pipe positioner manufacturer

The welding positioner is generally composed of the welding turntable. The welding turntable can choose autorotation and autorotation according to different welding lifting directions, so that the fixed workpiece can achieve the required electric welding,

welding positioner -

Welding Positioner&Turntable|L type, C type, and H type

The welding positioner mainly makes the workpiece in a suitable welding position through the lifting, turning, and other movements of the worktable.

Welding Positioner -

Welding Positioner: High Efficiency & Cost-Saving

The welding positioner produced by Fengwei is widely used in the machinery industry due to its advantages of high efficiency and saving labor costs.

welding positioner -

Choice of Welding Positioner|Welding turntable manufacturer from China

The basic shapes of commonly used welding positioners are outrigger type, tipping rotary type, and double column single rotary type.

welding positioners -

FENGWEI Welding Equipment-Welding Positioner

The composition and application of the welding positioner are mainly to make the workpiece in the best welding position through the lifting, turning, turning, and other movements of the worktable.

Welding Positioner -

High-quality welding positioner from China

The welding positioner is a special welding auxiliary equipment, which is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed.

welding positioner