"

Fengwei is a big factory, also effecient.

Delivery is on time, solution is ideal.

We have replaced 6 to 7 people

by Fengwei's automation solution,

and arrange to other tasks.

We are satisfied with quality,

and aftersales service.

Linda solves my questions quickly. good!

"

- Mr.Kalyana

The petrochemical industry plays a crucial role in enhancing the growth and economy of the world. Additionally, petroleum products produced in offshore and onshore exploration, refining, and oil production have also increased, resulting in increasingly complex waste production. This industry is a vital source of inorganic toxic and organic materials.

For the run of the industries present worldwide the top-quality equipment is mandatory. Several types of machinery producing industries are present worldwide but choosing the right one is a little confusing. Don't worry; we are here for your help. Giving the right solutions and shipments to your industry is our duty.

Here are 3 must haves of welding automations for the fabrication process in the petrochemical industry:

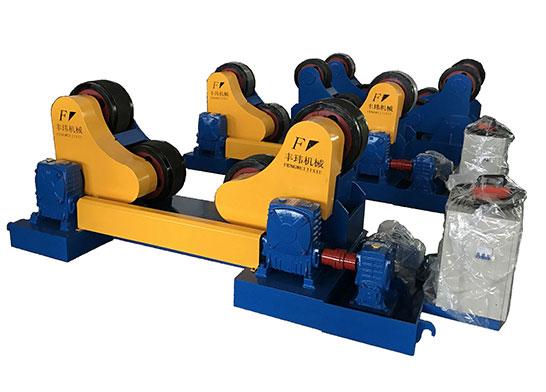

1) Conventional welding rotators

What does our industry produce for you?

Our company manufactures a range of equipment for the petrochemical industry, including stationary and process equipment for the refining, filtration, vacuum drying, and mixing techniques, always meeting the rigorous excellence standards this industry needs.

The responsibility of producing oil and natural gas is treated and transformed by the petrochemical industry. In addition to supplying our welding automation equipment especially welding rotators to various clients, many of whom use our welding rotators in the manufacturing process of pressure vessels. Different chemical processes are used in petrochemical plants to obtain various derivative commodities for use in the chemical, food, plastic, pharmaceutical, fertilizer, and textile industries. We help these industries produce the best way of material by using the best equipment and solutions served by us.

Following are some shipments that are sold by us. We have a wide range of equipment for every industrial use. Some information would help you to get comfortable with the equipment and services we provide.

What types of equipment are made for the petrochemical industry?

There are several shipments used in several industries. Some commonly used shipments by petrochemical and other industries are listed below. The function and information about the equipment listed below would enable you to understand its use and purpose in the industrial sector. Other than these, we have numerous kinds of solutions for every problem.

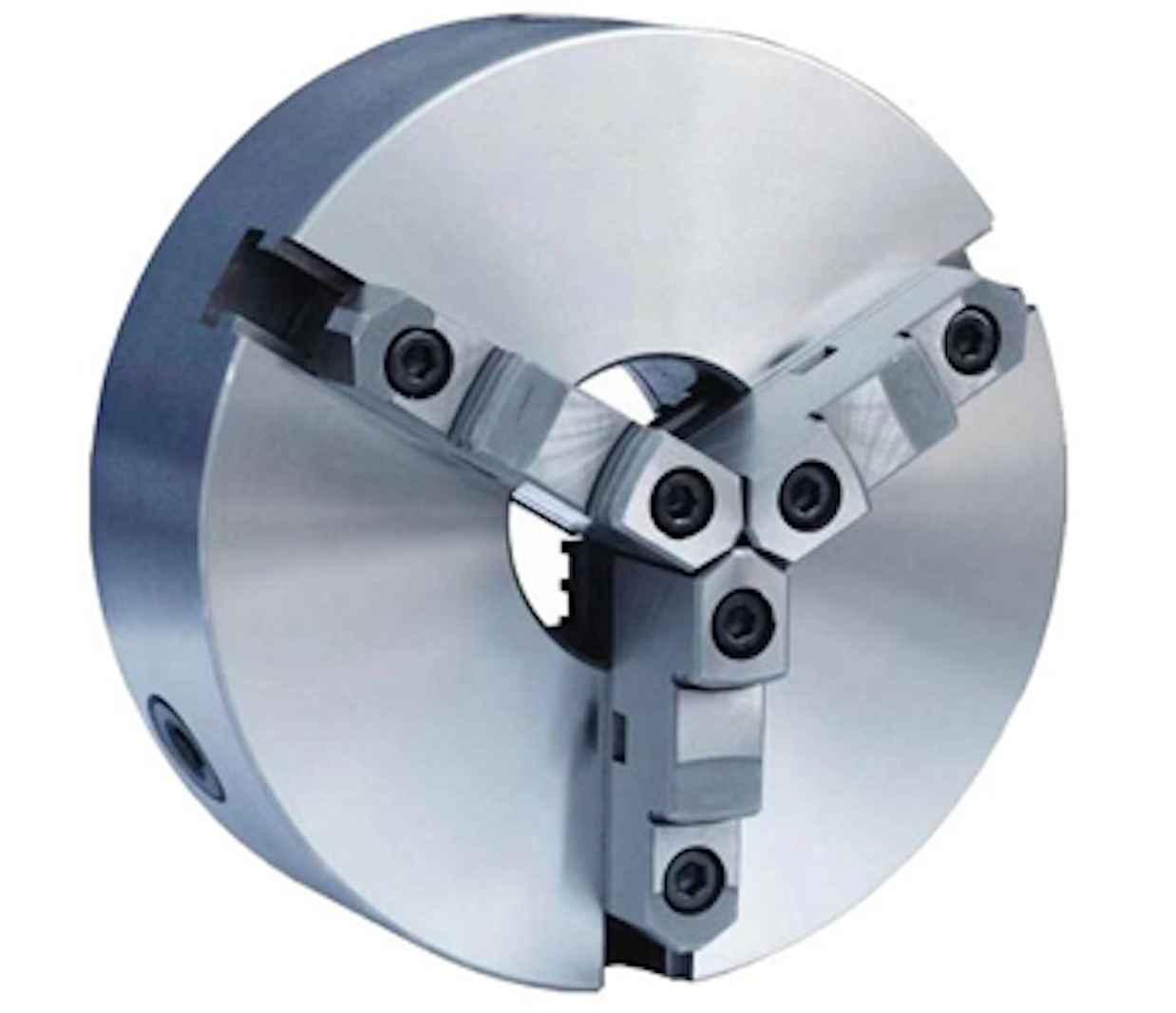

We manufacture welding automations to process Autoclave that is required in big industries including petrochemicals. The autoclave machines, which are welding rotators offer efficient results, simple operation, and minimal maintenance when it comes to general sterilization and special sterilization requirements. Our company is dedicated to making welding rotators with easier operation on processing sterilizers that are effective in sterilizing and that meet or surpass the minimum requirements of the sterilization industry. We manufacture welding rotators and welding positioners to fabricate autoclaves based on customer specifications as well as pre-engineered standard models. We can also add optional accessories for added flexibility to the operation of the machine.

The pipeline infrastructure is the vital function of the petrochemical industry for transporting the raw materials from the field to the industry or the service. As this task can have an immense harmful effect, there is a need for an expert to produce and implement useful welding automations to fabricate oil pipeline for your industry. Our most exemplary employees and mechanisms work for making assistant equipment. We have years of experience on welding rotators to fabricate pipes for the petrochemical industry and manufacturing its piping systems and accessories. Our company's engineers have the in-depth technical skills to design, develop layouts, build piping infrastructure and procedures, and develop integrated processes.

A liquid vacuum system is typically used to remove liquid from an area and put it into a holding tank for removal; therefore, vacuum tanks are usually portable. Many different liquids can be handled with vacuum tanks, such as water, sewage, oil, and molten metal. The capacity of vacuum tanks varies greatly depending on the application and is typically measured in gallons. We make tanks properly to perfection. As they need to be thoroughly cleaned between storing or processing, the interior walls must be smooth and free of grooves and imperfections. Steel, stainless steel, or aluminum are the most corrosion-resistant materials used for these tanks. In this case, due to its non-metallurgical material type, PU roller of welding rotator is a must rather than metal roller, otherwise the surface of vacuum tanks will be scratched.

Transport tanks are one of the primary sources for transporting the product to the customers. We understand that the chemical industries produce several types of substances, which are chemical bases, and sometimes it becomes difficult to transport these materials with proper safety measures. So the transport tanks are highly qualitative and fine for transporting for final use. Our solutions serve you the best cost-effective work flow of fabricating transport tanks for your client’s use. With taking all measures of safety and durability, these welding automations are excellently made under the eye of experienced engineers, and significantly help you produce a highly precised transport tank.

The vehicle-mounted tanks are a durable way of transporting your chemicals through roads. Industries like petrochemicals produce hazardous chemicals which need to be transported with care and proper safety. So in this field, clients require for non-corrosion, smooth, or aluminum tanks for vehicles. Similar to the fabrication request on vacuum tanks, your selected welding rotator must have a PU typed roller instead of metal roller. One one hand, it helps to avoid any scratch from the surface of tanks in the process of weldment and blasting. On the other hand, we specially design anti-drifted welding rotators to ensure the safety while fabricating such heavy-duty and large dimensional cylinder objects.

We manufacture several types of welding rotators to fabricate pressure vessels for a vast range of applications. Our clients who make pressure vessels, also make sugar tanks, blowdown tanks, filter vessels, and more. With advanced techniques and intelligent engineers, we have designed the best welding automation for making pressure vessel, in terms of cost effective and efficient work flow.

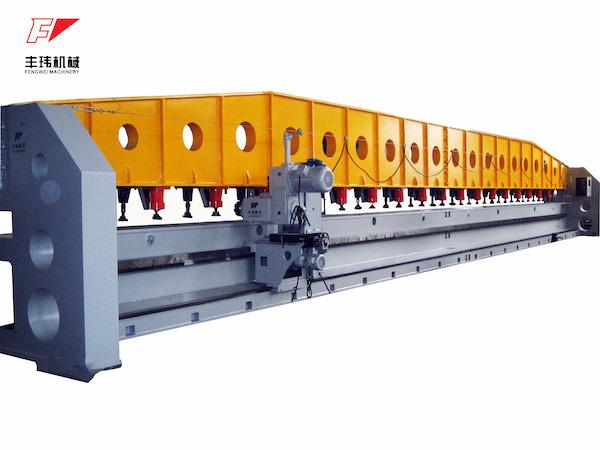

Industry requires steam, so big percentage of our clients are professional at manufacturing boilers. With higher demands of steam boilers, more stem boiler producers come to us for an automatic production process. Again, we suggested to use welding manipulators and equipped with welding rotators. These welding automations are easy to uphold and cost-effective too. We try to make your system in a systematic way.

Our first property is to give good service to the customer. We deliver our service on time. Our equipment is always pre-tested and delivered to you with all safety measures. Our team always stands first for maintaining the equipment with our ironclad guarantee. Thus, we can assist and have experience in several industries, whether you are looking for ways to enhance productivity, boost the quality of welds, reduce fatigue, improve health and safety, or whatever you are trying to accomplish.

Conclusion: We provide the best service to you with our well-qualified staff. To satisfy our customers, we take every single step with the thought of your goodness and profit. With cost-effective and durable equipment, we serve you. Reach out to us for beneficial service.