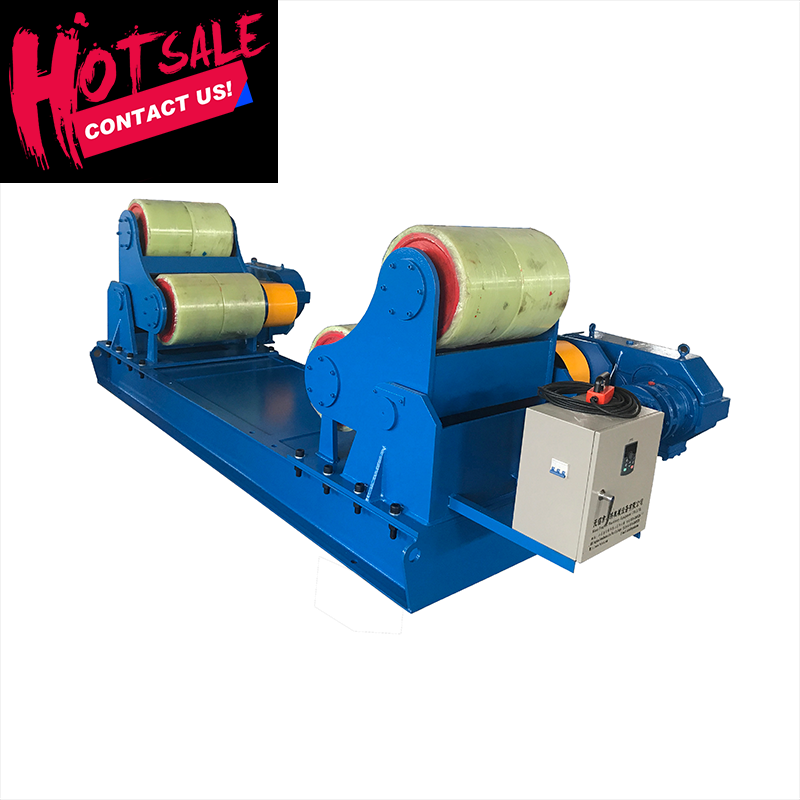

self-adjusting welding rotator

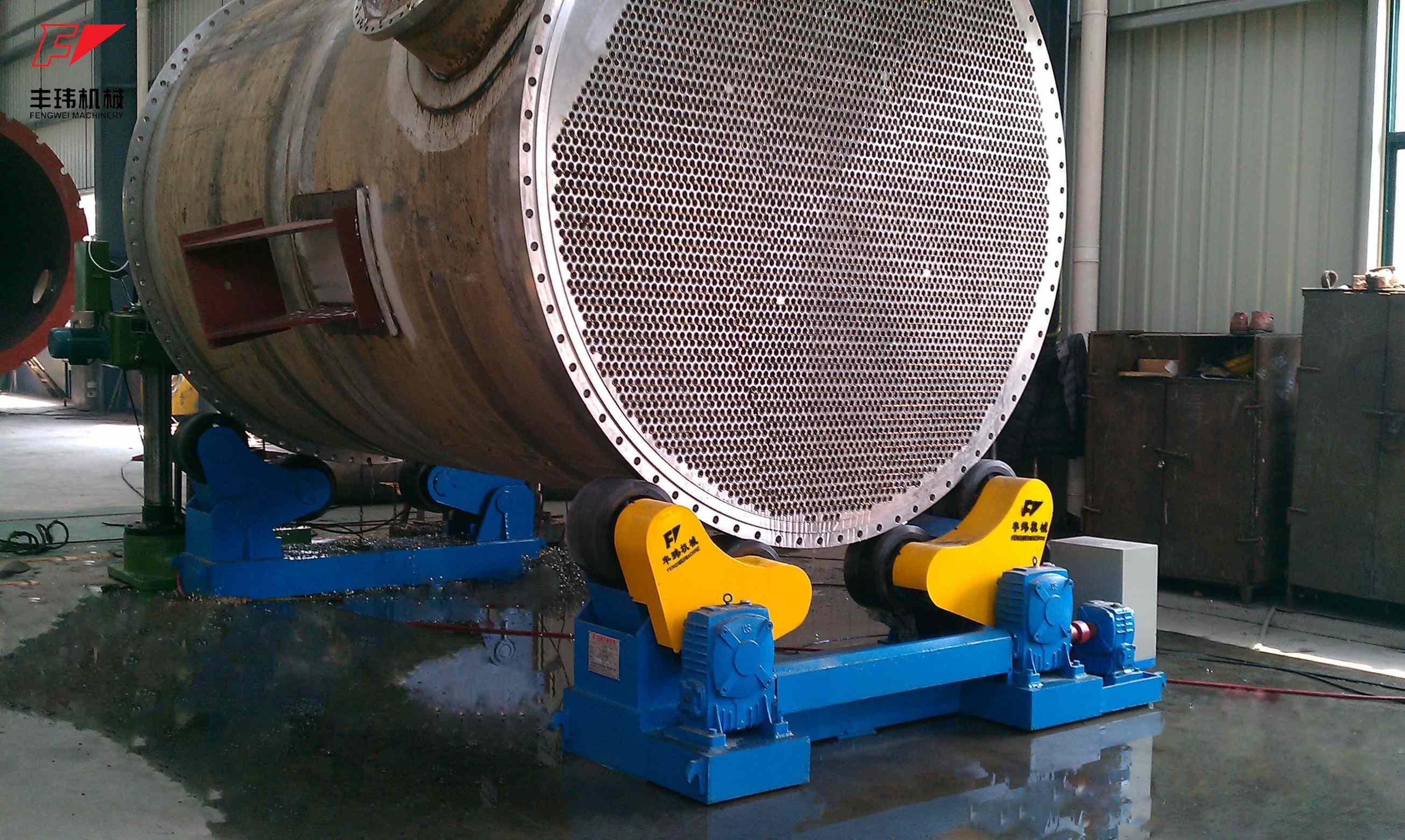

Fengwei has 20 years of experience in the design and development of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world.

Fengwei has 20 years of experience in the design and development of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world.

Fengwei has 20 years of experience in the design and development of types of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world. In pipeline welding, boilers, containers, and other industries, also play a crucial role in the welding of some irregular welding parts. However, when the welder is operated, accidents are often prone to occur, due to improper operation of the welder. Or the placement is not good, resulting in many unnecessary dangers. Next, let's talk about how to avoid the dangers of welding, that is, the operation safety guide.

Fengwei has 20 years of experience in the design and development of types of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world. In pipeline welding, boilers, containers, and other industries, also play a crucial role in the welding of some irregular welding parts. However, when the welder is operated, accidents are often prone to occur, due to improper operation of the welder. Or the placement is not good, resulting in many unnecessary dangers. Next, let's talk about how to avoid the dangers of welding, that is, the operation safety guide.

Position of self-adjusting welding rotator and workpiece

1. The self-adjusting welding rotator should be installed in a sturdy, ventilated, rainproof, moisture-proof, dust-proof place, and away from severe vibration and bumps.

2. Keep away from and strictly prohibit corrosive liquids from being sprayed on the equipment. When the main and driven rollers are installed at the same time, it must be ensured that the main and driven frames are level and the same height, and the centerline is on the same straight line.

3. Requirements for placing the workpiece: The diameter and weight of the workpiece should be strictly implemented in accordance with the design regulations, otherwise safety accidents are likely to occur. According to the length of the equipment, the distance between the main and auxiliary wheels should be adjusted appropriately.

Operating Requirements for Welding rotator Rollers

1. The rubber roller of the welding rotator is gradually replaced by the polyurethane roller. The ordinary type of rubber roller is only suitable for working at room temperature. Possible wheel damage. The polyurethane roller has the characteristics of high strength, compression resistance, wear resistance, oil resistance, acid and alkali resistance, corrosion resistance, tear resistance, impact resistance, a wide range of hardness, firm adhesion to metal, and no degumming. Polyurethane has good properties such as high load-bearing, shock absorption, and buffering, has good adhesion with metals, and has a wide range of hardness. However, paying attention to maintenance can increase the service life of the machine.

2. When the welder uses it, it should be ensured that the roller fully contacts the workpiece, and it is strictly forbidden for the welding seam or sharp parts to contact the roller of the welding rotator. At the same time, when the welder lifts the workpiece, it needs to be handled with care, and it is strictly forbidden to hit the roller to prevent the roller or other components from being damaged.

Instructions for use of the welding rotator

1. Debug the welding rotator: when starting, gradually adjust from low speed to high speed; when changing the direction, the conversion can only be carried out after the motor stops, otherwise, it is easy to cause the motor to burn; when running, it is strictly forbidden to separate the man-machine, and the workpiece is strictly prohibited within the radius of rotation stand man.

2. In order to ensure the performance of the equipment, each transmission part should be filled with lubricating oil before use, and the equipment should fill in the daily inspection and maintenance record form. After the whole machine has been used for a period of time, it should be checked regularly, and the maintenance record form should be filled out.

3. The equipment uses a three-phase 380V AC power supply. The power supply line must pass through the air switch for safe operation. When debugging the equipment, turn on the power supply, press the start button, and observe the rotation of the driving wheel. Whether the speed adjustment is normal. The power should be cut off immediately, and the cause should be found. After the fault is eliminated, the power can be turned on again to test the machine.

4. Check and remove obstacles on the device before use, and special personnel is required to use and keep it. Welded spinner parts (rubber wheels or polyurethane rollers) should not come into contact with oil and sparks.

The function of Fengwei self-adjusting welding rotator

After twenty-five years of exploration and updates by Fengwei, the welding rotator has been constantly advancing and creating with the times, and its functions have been better improved. Among them, the self-adjusting welding rotator is a typical case. According to the needs of all walks of life, he has been recognized by many partners.

1. Not all welding workpieces are regular and the same size. However, the swing angle of the wheelset can be automatically adjusted according to the diameter of the workpiece, and automatic centering can be realized. When matched with a welding manipulator and a welding manipulator, it can also realize the welding of the inner and outer longitudinal seams and the inner and outer circumferential seams of the workpiece.

2. Our welding rotator also has the characteristics of low transmission noise and stable rotation of the workpiece. During operation, it can realize the welding, polishing, rubber lining, and assembly of the cylindrical cylinder. The roller speed of the welding rotator should be within the A smooth, uniform state. Crawling is not allowed.

3. It has the functions of overvoltage protection and self-protection, and also has fault display and storage functions, automatic air switch short-circuit protection and preset parameters.

4. Properly adjust the height of the main and driven rollers, and can also perform assembly and welding of cones and segments with unequal diameters.

5. For some non-circular elongated welding parts can be clamped in a special ring clamp, and the welding operation can also be carried out on the welding rotator.

6. The self-adjusting welding rotator adopts digital adjustment and display technology for the rotation speed of the rollers. The setting of the welding speed is very intuitive and accurate, which reduces the difficulty of operation for workers.

7. The manufacturing and assembly accuracy of the welding rotator should meet the requirements of the 8-level accuracy in the national standard. The welding rotator shall be made of high-quality steel. If a base of welded construction is used, a stress relief heat treatment must be performed after welding.

8. The welding rotator must be equipped with a reliable conductive device, and the welding current is not allowed to flow through the bearing of the welding rotator.

9. When the cylindrical workpiece is welded on the anti-axial movement welding rotator, the axial movement of the workpiece during the entire welding process should be ≤±3mm.

10. The center distance of each pair of rollers of the welding rotator must be adjusted according to the diameter of the cylindrical workpiece to ensure that the wrapping angle between the two rollers is 45° larger than 110°.

11. Equipped with 15m control cable, roller forward and reverse switch, near control, and remote control switch.

12. The roller is preferably made of polyurethane or shunning rubber. An adjustable welding rotator is a displacement machine that drives the weldment to rotate by means of the friction between the active roller and the weldment. Only one roller part of the adjustable welding rotator is the driving roller part and the other is the driven roller part. The drive device adopts a variable frequency speed regulation motor, which drives the roller parts through the reducer, and drives the welding parts for welding rotation. The adjustment of the distance between the roller parts in each welding rotator is done manually, according to the condition of the weldment, using the positioning bolts.