Welding Positioner

Model:ZHB

Loading Capacity (kg):20 - 20,000 above

Rotation Speed (rpm):0.2-2 (per request)

Overturning Speed (rpm)):0 - 1.1 (per request)

Worktable Diameter (mm):400-2,000 (per request)

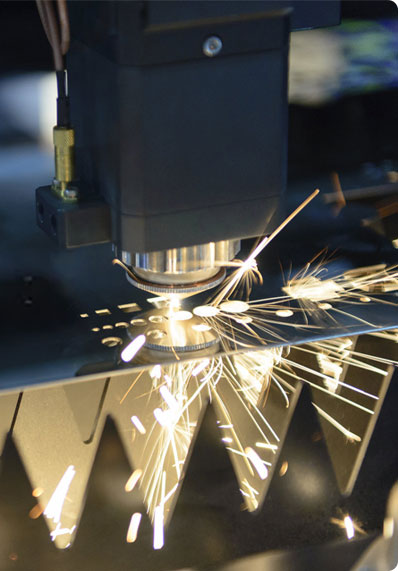

Application:Welding, Grinding, Sputter

-

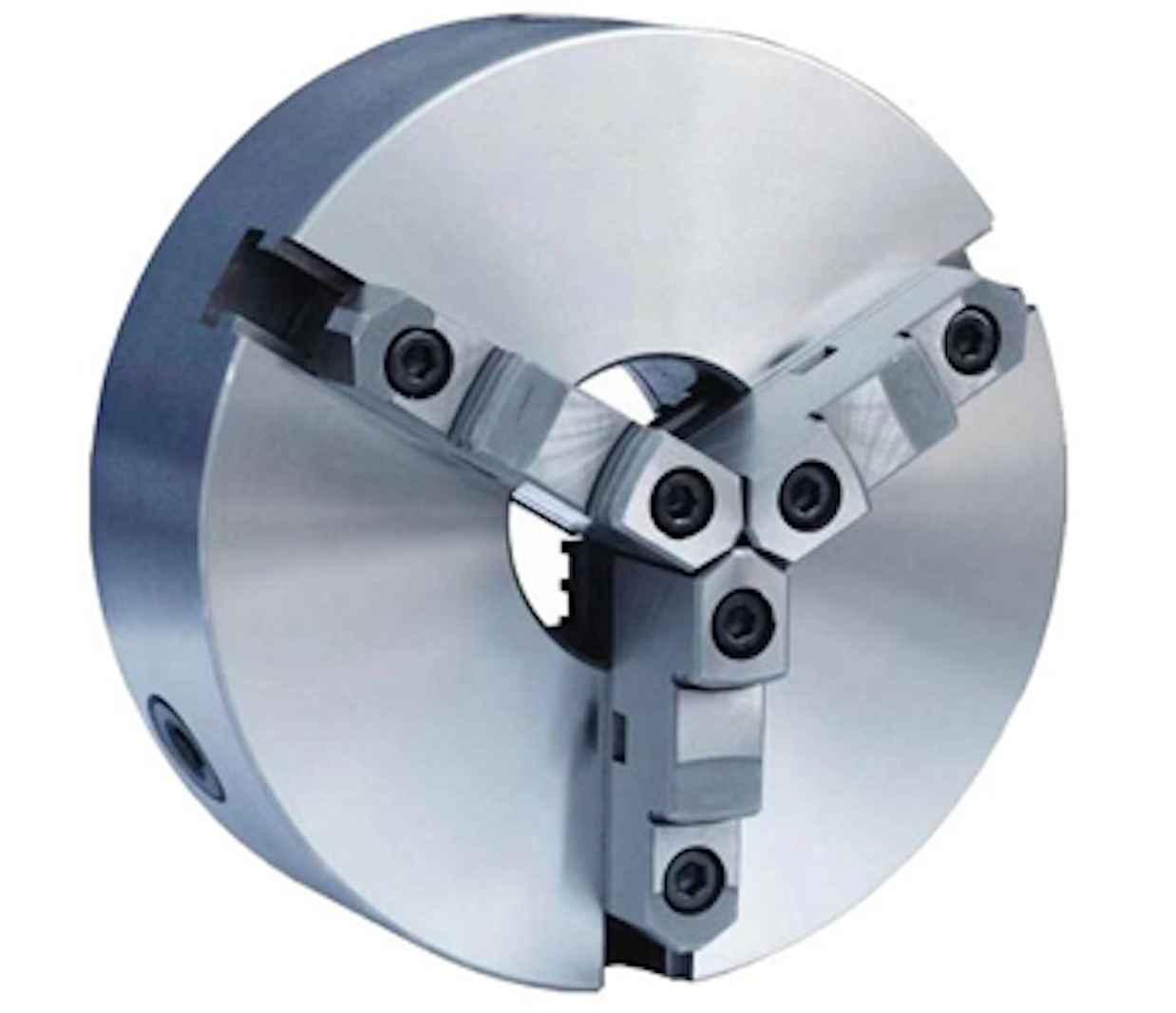

3 Jaw Chuck

Fengwei mainly supplies a full range of manual 3-jaw self centering chucks as one of standard accessories for all types of welding positioners.

-

Small Welding Positioner

The small welding positioner is a welding automation equipment that Fengwei is selling. It is suitable for welding and assembling some small welding workpieces.

-

300kg welding positioner

The welding positioner is widely equipped with welding manipulator to be a welding center, which achieves linkage work accordingly.

-

Pipe Welding Positioner

A pipe welding positioner is a mechanical component of the system that holds and rotates a workpiece so that a welder can paint at the correct angle and on a level surface.

-

L type welding positioner

L-type welding positioner, also known as welding turntable. Positioner is an indispensable equipment in the manufacturing industry, categorized as one of three welding auxiliary machines in the welding field.

-

Welding turntable

Welding turntable plays a vital role in welding auxiliary equipment. Welding and assembly of large objects cannot do without its help. It is widely used in pressure vessels, tank reactors, wind towers, iron towers, etc.

-

Elevating welding positioner

What is a Elevating welding positioner? It can adjust the height of the worktable by adjusting the position or electric height, Elevating the welding changer, and it is used to be very wide.

-

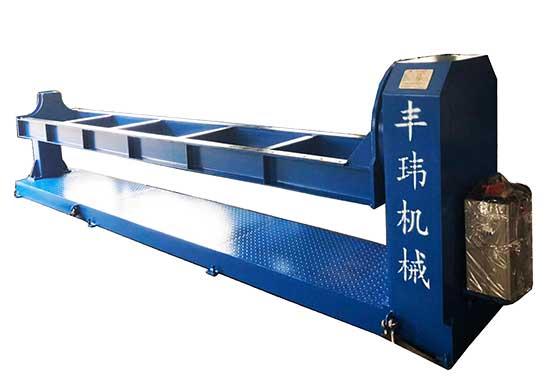

Head And Tail Stock Welding Positioner

Head and tail stock welding positioner is widely used in the fabrication field of wagons, carbody or metal frames. This type of welding positioner consists of 2 body sets on each side, which is a crab likewise to clamp the heavy-duty frame works between.

-

Benchtop Positioner

This equipment is specialized and is intended primarily to be used for pipe welding and details. Positioners can perform many operations with tube stock as part of their mission. Positioners are capable of performing all types of manual and automatic weld

-

Welding Positioner

Fengwei Machinery has a wide variety of welding positioner for your choice, most of which are customized, including: benchtop rotary table, head and tail stock positioner, U-shaped welding positioner, L-type double-rotary welding positioner and fixed weld

Welding Positioner

Learn more Welding Positioner

> Welding Positioner: High Efficiency & Cost-Saving

> Welding Positioner&Turntable|L type, C type, and H type

> Welding positioner chuck maintenance

The welding positioner is mainly used to assist welding. The workpiece to be welded is passed through the rotating platform of the welding positioner to achieve the best welding position. There are many types of welding positioners. Among them, the most common ones are cantilever welding positioners, seat welding positioners, and two-seat welding positioners, and their forms are more L-shaped, U-shaped, and so on.

Fengwei welding equipment has deep experience in the production and research and development of welding positioners. After more than 20 years of accumulation, Fengwei welding positioners have been upgraded many times for all fields of demand. It can be perfectly suitable for racks, The turning, displacement, and welding of non-long workpieces such as machine bases, flanges, and heads can also be used for assembly, cutting, inspection, etc. There are many welding positioners under Fengwei Machinery. The most common ones are Elevating welding positioner, Head And Tail Stock Welding Positioner, L-shaped welding positioner, U-shaped welding positioner, hydraulic welding positioner, and special welding. Displacement and so on.

Elevating welding positioner

Elevating welding positioner can adjust the position of the entire welding table by manual or electric two methods. And the application range of this welding displacement is extremely wide, it can be applied to the welding of almost all workpieces, and the tiltable angle can reach 135 degrees, and it can also achieve higher. The height of the worktable can be adjusted by manually adjusting the pin position, hydraulic lifting, or electric screw height adjusting to adapt to different types of workpieces.

(1) The load works smoothly and reliably and can be braked at any position.

(2) Anti-interference electric control system, remote control technology of hand control box.

L-type welding positioner

The L-shaped welding positioner is also one of the popular products in the welding positioner series. It is mainly composed of a base, a column, a motor box, an L-shaped support arm, and a rotary table, and the structure of the L-shaped welding positioner is also very simple:

- The column is fixed on the base

- The motor box is installed on the top of the column

- The L-shaped support arm is installed on the upper part of the fixed plate at the front of the motor box

- The turntable is installed on the top of the front end of the L-shaped support arm.

The L-type welding positioner has many advantages. Compared with the traditional welding positioner, it has very high flexibility and the overall design structure is relatively simple. After many user feedbacks, Fengwei has received feedback from many small partners: Fengwei's equipment has a high degree of freedom and reliable carrying capacity; once the factory is purchased, it only needs to simply install the workpiece and pass it The pre-set program operation can complete the welding operation of the entire workpiece, which greatly improves the production efficiency.

U type welding positioner

The structure of the U-shaped welding positioner is relatively simple, mainly including a base, two uprights, an overturning pillar, a rotating material table, and an electric shock box.

- A first column and a second column are respectively provided on both sides of the base, and a turning support column is provided between the two columns

- Both sides of the flip support column are rotatably connected with the first and second columns through the first drive structure

- A rotating material table is set on the top of the flip support column

- The rotating material table is connected with the turning support column through the second drive mechanism.

By placing the material on the rotating material table of the U-shaped welding positioner, and by turning the support column and the rotating table, the adjustment of the material in two directions can be realized, and the structure is simple and the assembly is convenient.

There are many styles of welding positioner designed by Fengwei Machinery, almost from a single model to the entire production line, from a single industry to a multi-industry refinement, to meet the needs of various industries.

PDF documents related to FENGWEI welding positioner:

More about welding positioner

Welding Positioner: High Efficiency & Cost-Saving

The welding positioner produced by Fengwei is widely used in the machinery industry due to its advantages of high efficiency and saving labor costs. Through simple operability, it only takes a short time to allow the operator to work proficiently, but for beginners In terms of operation, some aspects are still needed. What maintenance measures need to be taken after the welding positioner has problems?

After years of iteration, the welding positioner currently plays a vital role in the assembly and welding of large pipes. Usually, the welding positioner can complete the automatic and mechanized welding device by changing the position of the welding machine, welding, and welder. If the equipment is used to complete the work, the entire auxiliary welding time can be quickly shortened and labor production can be improved. efficiency, and improve the quality of welding, to a large extent to play the effectiveness of different welding methods.

Under the international call, the popularity of new energy and environmental protection equipment, the demand for welding positioners in these industries continues to increase, and many manufacturers have begun to serialize the production of welding positioners, of which every year there will be many The mechanical parts of automobiles, engineering, locomotives and medium-sized single-sided slewing are put into use, and the control system and drive also use relatively advanced AC motor frequency conversion speed regulation, DC motor to debug the thyristor, servo The motor and drive system, as well as the microcomputer and industrial computer to control, etc., which makes the welding positioner more and more users, but at the same time will encounter many problems in the process of use.

1. There are many reasons for the overturning motor of the worktable. We analyze the following one by one:

(1) The contact of the contactor is not in good contact, the phase is missing, and the coil is faulty. This way the contactor contacts can be handled and the contactor replaced if necessary.

(2) The thermal relay fails or malfunctions. Just replace the thermal relay or reset it.

(3) If the button fails, repair or replace the button.

(4) The motor holding brake is not opened or the motor load terminal is loose, and the contact is not good: check the motor holding brake device and fasten the load terminal.

2. After pressing the button, if there is no lifting action or one-way action, it may be because the limit machine is stuck or the contact is faulty, so it is good to replace the limit. It may also be that the contact of the button is not good or the return spring of the button is damaged. It is good to repair it. If it cannot be repaired, replace the button. It is also possible that the thermal relay setting current is small and malfunctioning or the thermal relay is faulty. You can adjust the setting current or replace the thermal relay. If the motor does not move, there is a buzzing sound, the contactor is out of phase, and the load terminals are not in good contact. If such a situation occurs, check the contactor and replace the contactor if necessary, and tighten the load terminals.

3. The rotary table of the welding positioner does not move.

(1) If the speed regulating potentiometer of the remote control switch fails, the speed regulating potentiometer can be replaced.

(2) If the worktable is in the forward direction and the reverse direction of the relays CR1 and CR2, you can check whether the wiring is loose and whether the relay is faulty. Tighten the wire or replace the relay.

(3) The contact of the inverter panel is not good, and the screws are loose. You can check the inverter and tighten the screws to make them in good contact.

(4) Check whether the contactor KM5 of the rotary brake of the worktable operates and whether the brake is open. You can check whether the brake wiring and the contactor are faulty, tighten the screws, solve the fault of the contractor, and replace the contactor if necessary.

(5) Check whether the near-control or remote-control switch is in place and whether the button is faulty, and whether the switch or button can be replaced.

(6) The rising limit switch connected to the inverter is faulty, and the limit switch can be replaced.

(7) Check whether the wiring of the circuit breaker on the front side of the main circuit of the inverter is firm and whether there is a phase loss. If the wiring is loose, tighten the wiring terminals to make them in good contact. If the circuit breaker is faulty, replace the circuit breaker.

(8) If the brake holding brake is not opened, check the brake device, first check whether there is any fault or damage, and replace it in time if there is any.

The maintenance of the welding positioner can increase the durability of the machine. As a senior manufacturer and supplier of welding positioners, Fengwei has carefully produced each machine, and we provide tailor-made products for different industries. Customized programs, if you are looking for a partner, you can contact us directly.

Welding Positioner&Turntable|L type, C type, and H type

The welding positioner mainly makes the workpiece in a suitable welding position through the lifting, turning, and other movements of the worktable. It can be matched with welding manipulators to form an automatic welding machine, and can also be matched with automatic welding equipment such as welding robots to realize automatic welding. At the same time, various special welding positioners can be designed and customized according to the user's workpiece and process requirements.

However, there are also three types of welding positioner structures. One is the single-turn type, which is widely used. To meet the needs of different workpiece clamping, there are also three basic types, a vertical type, a horizontal type, and a double-seat type. The double seat is also divided into two types: fixed tailstock and movable tailstock. There is also a double rotary type, which is mainly to adapt to the clamping needs of different workpieces and to consider the reasonable force of the structure. There are also three basic types, L type, C type, and H type. There is also a tip-and-turn type, which also has a different structural design.

Parts of welding positioner

The main structure of the welding positioner is a rotary head, a positioner, and a controller. The rotating speed of the rotary head can be adjusted by itself, with an independent speed control circuit, and the DIP switch can directly set the initial value of the weld length. The inclination angle can be adjusted according to the needs of the weldment, and the welding torch can also be lifted pneumatically. The motor of the welding positioner drives the multi-stage worm gear reducer to drive and realizes the rotation of the worktable through the main shaft. It has the characteristics of stable operation, and the rotation speed is 0.1 ~ 3r/min. The handwheel is driven by a worm and a worm wheel, thereby driving the worktable to turn bricks within a range of 120°. (displayed by the dial), the turning torque is large, the positioning is reliable, and it has a self-locking function.

Advantages of welding positioner

1. It uses full hydraulic pressure for transmission, has a highly integrated valve block, and has a large flow diameter to reduce system pressure deficit.

2. High sealing performance, it uses imported sealing components.

3. The oil temperature is well controlled, with ingenious ideas and special oil circuit preset, which can make the hydraulic system in good condition, and can be easily competent even when working under long-term heavy-load working conditions.

4. The combination of the cycloid gear motor and the involute speed reducer successfully realizes the step-less speed change of the cart and the rotation of the gantry. There is also a special clamping mechanism with accumulator pressure compensation to make the clamping firm.

5. Its three-level linkage, because the structure makes the jaws rise and fall in parallel, the jaws tilt, rotate 360 degrees, and rotate freely and flexibly in the three-degree space.

6. The power input of the whole machine is more than 70% energy-saving compared with similar positioners.

7. The shape of the manipulator of the welding positioner is very good, the structure is compact and close, and the movements are flexible. It can particularly well complete the actions that the positioner cannot complete so that the operator has a feeling of man-machine integration.

8. The equipment is equipped with an industrial semi-automatic control input port, which can provide convenient conditions for your facility to upgrade so that its quality is always at the forefront of similar models.

Welding positioner chuck maintenance

The use of the welding positioner is mainly suitable for the processing of some large factories. The welding work is inseparable from the use of the positioner. It is called a welding auxiliary machine, so it can be widely used and can always perform well when used. use effect.

The development of welding positioners in the machine tool industry is developed with the application and development of the welding structure of machine tool products. The products of the machine tool industry are mainly metal cutting machine tool products, forging machinery products, foundry machinery products, woodworking machine tool products, and tools. Among them, metal cutting machine tools, forging machinery, and casting welding displacement machine products are the main fields of displacement machine application in the machine tool industry.

The welding positioner has gradually developed into the main technology of the machine tool industry, and its main performances are as follows.

(1) Some key enterprises have built welding factories or metal structure factories of a certain scale and established a complete welding management system. Absorb and digest the welding technical standards of imported products, implement professional standards, and formulate enterprise standards.

(2) Improve the welding process flow, and develop from single processing technology to a series of new comprehensive engineering technologies such as raw material pretreatment, cutting, forming, welding, post-welding inspection, and post-welding treatment.

(3) The application of numerical control cutting and computer programming routine technology has changed the blanking technology of traditional manual cutting and reduced mechanical processing.

(4) The new technology of promoting vibration aging is realized, the residual stress of the welded structure is reduced, the purpose of homogenization is achieved, the deformation of welded parts is reduced, and the accuracy is stabilized.

The welding positioner can ensure the smooth progress of the welding process when it is used. It can not only play a good auxiliary role in welding but also have a good effect in later use. This credit is mainly due to the welding positioner. When using, there is an important accessory---welding chuck. The application of the chuck can ensure the normal use of the welding positioner. Therefore, in the later maintenance, attention should not only be paid to the maintenance of the welding positioner, but also the maintenance of the chuck. maintain:

1. After the chuck is used, it is necessary to use tools such as air guns to clean the welding chuck body and slide the surface of the welding positioner. As a result, good accuracy can be ensured even after using the chuck for a long time, so regular lubrication of the chuck is important.

2. Apply molybdenum disulfide grease (black) at least once a day, and pump the grease into the grease nozzle of the welding chuck until the grease flows from the jaw surface or the inner hole of the welding chuck (the inner hole protective cover). and connecting nut) until it overflows.

3. To prevent rust inside the chuck, the clamping force will drop, and the workpiece cannot be clamped, so use cutting oil with anti-rust effect, and the use of cutting oil can prevent the inside of the chuck from rusting.

4. After the work is completed, it is necessary to clean the main body of the welding chuck and the slide surface with an air gun, etc.

5. The chuck should be removed and cleaned at least every 6 months, keep the bending surface of the chuck claw clean and lubricate it to prolong the life of the chuck.

6. Check all parts for cracks and wear, and clean the cast iron at least once every two months. If there is serious damage, it needs to be replaced with new products immediately.

7. Each workpiece needs to use different clamping methods, and using it to clamp irregular workpieces will damage the welding chuck.

8. In the case of abnormal chuck pressure, if the chuck is clamped with high pressure, the life of the chuck will be reduced. Therefore, if the gap of the chuck is found to be too large, it is necessary to replace the new chuck immediately.

When the chuck of the welding positioner is used, it is necessary to pay attention to regular maintenance to prevent the phenomenon that affects the overall quality. In the later maintenance, it is necessary to ensure that the quality of the chuck is not damaged, to ensure a good maintenance effect.

Guidelines For Welding Positioner

Free technical solution for welding positioner. Direct manufacturer of benchtop welding positioner, head and tailstock positioners and turntable for welding. Easy operation. Ready to use in delivery.

-

Features of various welding positioners

Through the rotation and flipping of the welding turntable, the workpiece welding seam is in the best welding position for welding or rotating welding with other equipment.

Welding Positioner -

Main degree of freedom full function of welding positioner

Considering the station design and stability, two or more welding positioners are combined and designed, so that there are a variety of station conversion and combined multi-degree-of-freedom welding positioner products.

Welding Positioner -

Best Price Welding Positioner - China Manufacturers and Suppliers

The welding positioner is a special welding auxiliary equipment, which is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed.

Welding Positioner -

Various types of welding positioners|Welding turntable

A welding positioner is a piece of auxiliary equipment for welding automation dedicated to welding. It is suitable for the welding position of rotary operation to obtain the ideal processing position and welding speed.

Welding Positioner -

Welding positioner with many advantages: Manufacturers & Suppliers

The FENGWEI welding positioner is generally composed of a table rotation mechanism and a turning mechanism. Through the lifting, turning, and rotation of the table, the workpiece fixed on the table can reach the required welding and assembly angle.

Welding Positioner -

More intelligent and functional welding turntable

The Welding Turntable is a special welding aid for reverse working welding offsets to achieve the desired machining position and welding speed.

Welding Positioner