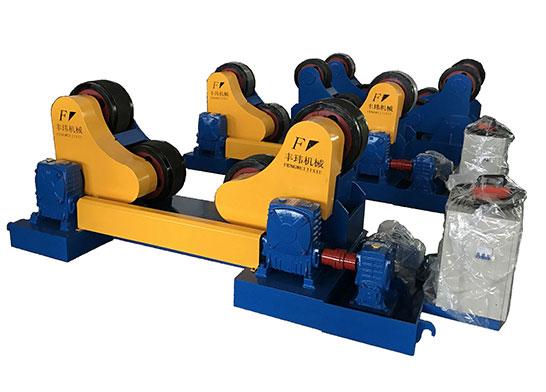

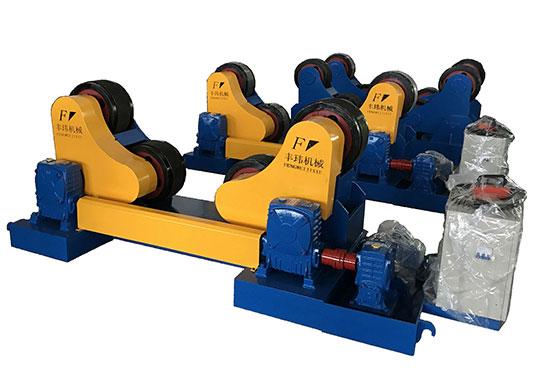

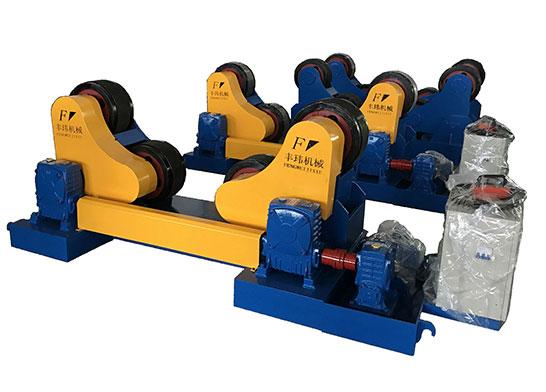

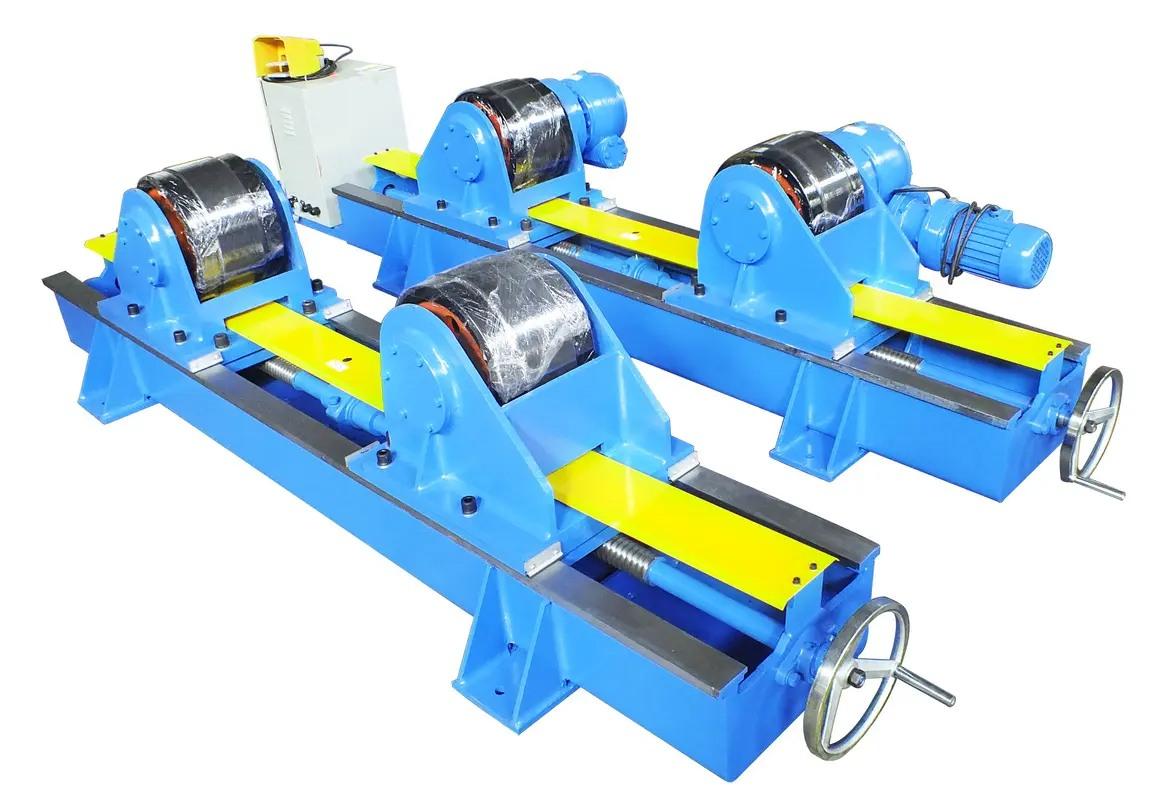

Welding Rotator

Model:Adjustable、Self-aligned、Fit up、Growing line

Loading Capacity (kg):1,000 - 3,000,000 above

Diameter Range (mm):200 - 7,500 above

Roller Material:PU or Metal

Wheel Linear Velocity (m\h):6-60 (per request)

Motor Power (kw):0.18-11 above

The welding rotator is mainly used for the assembly and welding of the cylindrical shape; if the height of the main and driven rollers is properly adjusted, the assembly and welding of the vertebral body and the unequal segmented rotary body can also be carried out; for some non-circular elongated If the weldment is installed in a special ring clamp, the welding operation can also be carried out on the welding rotator; there are many specifications of the welding rotator, and it can also be used with manual welding as a device for detecting and assembling cylindrical workpieces . The use of welding rotator can greatly improve the quality of welding seam, reduce labor intensity and improve work efficiency.

-

Turning roller

A turning roller refers to a device that drives the cylindrical weldment to rotate by means of the friction between the weldment and the driving roller. The Turning roller series consists of self-adjusting, adjustable, flat car, tiltable, anti-axial movem

-

80T walking welding rotator

The 80T walking welding rotator is developed according to the technical requirements stipulated in JB/T9187-1999 "Welding Rotator".

-

1 Ton Adjustable Welding Rotator

There are two main types of 1 ton adjustable welding rotator, one is conventional welding rotator and the other is screw welding rotator.

-

Pipe Rotator For Welding

FENGWEI pipe rotator is a tool that makes welding pipes and other circular items easier. By integrating two rolling metal pieces, pipe rotator can work with small or huge sizes while saving time.

-

30ton lead screw welding rotator

Lead screw welding rotator is composed of 1 power and 1 idle roller, i.e. 1 set including driver and idler). 30 ton is one of popular lead screw models selected by clients to fabricate cylindrical objects.

-

40 ton self aligning welding rotator

40 ton welding rotator is one of models among Fengwei made self aligning turning rolls. Likewise, the model consists of 1 power and 1 idler, each can load 20 ton of cylindrical objects respectively.

-

Welding Turning Roll

If you are dealing with welding and fabrication work regularly, Pipe Welding Rotator is the best tool for your company to move any cylindrical workpiece for the purpose of welding.

-

10 Ton Welding Rotator

A set of 10 ton welding rotator is composed of 1 power + 1 idler. Each one can load maximum 5 ton respectively.

-

100T self-aligning welding rotator

As a kind of welding rotator, a self-aligning welding rotator plays a vital role in the welding and assembly of workpieces. When facing large objects, it is necessary to prescribe the right medicine and choose a larger configuration welding rotator.

-

Polyurethane Roller

Polyurethane Roller(PU Roller) is used in various industries for its high wear resistance, high bearing capacity, and excellent tear resistance.

-

welding rollers

Welding rollers, also called welding rotators, play an auxiliary role in welding large-scale equipment. There are many types of welding roller racks, including self-adjusting, adjustable, flat-car, tiltable, anti-moving, and explosion-proof.

-

Welding rotator with walking

Mechanism of Welding rotator with walking,Two sets of driving devices are installed on the driving roller. The driving device consists of the motor and reduce.

Welding Rotator

The whole welding rotator has strong rigidity and stability, beautiful appearance, reliable performance, simple maintenance and long service life. Learn more about the details and types of welding rotators.

Learn more Welding Rotator

> Adjustable Welding Rotator - Explosion-Proof & Anti-Channeling

> Improve Weld Quality|Welding Rotator

> Performance characteristics of FENGWEI self-adjusting welding rotator

If you are dealing with the welding process regularly, welding rotators play an essential part in your welding industry. By using them, you can deal with large cylindrical objects in order to do the welding process effortlessly. They are liable to weld the outer as well as the inner part of the object at ease.

Welding rotators help in rotating the object with the necessary friction between the roller and the welding object to rotate it. For rotation of the object, they contain a base, power driving tool, rollers, and other outer structures. This equipment is the best solution to save time and reduce labor costs, and they can perform even light or heavy-duty tasks quickly and effectively.

There are different types of welding rotators available in the market with a bit different features. If you want to know about them for increasing the productivity of the company, you can find them below:

Fit-up rotator

You can find this fit-up rotator best as it comprises four independent fill-up rollers, and the work of rollers is to lift the process that is supported by the cylinders. Welding Rotator is used to assemble the section pipes such as tank application, wind tower, etc. These are great options to reduce the labor cost and help you to enhance the work performance that leads to your company with an increased conversion ratio.

Pipe Fit Up Turning Rolls

The 20 Tons conventional turning rollers

These conventional rotators are eligible to load the 20 tons loads with a suitable workpiece of 500-3500mm. It contains a rubber wheel of 350*1290 mm along with a metal wheel. You can adjust the distance of the wheel manually with screws or bolts provided with the roller separately. The power of the motor is 2X1.1 KW, and that is the best to handle a large workpiece with minimum effort. Further, these rollers are used in pressure vessels, chemical equipment, oil and gas, and many other workpieces. So, you can adopt them also to give a boost to your overall work performance.

20 Tons conventional turning rollers

The 10 Tons conventional roller

These 10 tons conventional rotators are liable to load the 10 tons of loads efficiently with the suitable workpiece range of 320-2800 mm. The wheel can be easily adjusted by the bolts and screws that are given separately by the company. The overall dimension of this welding rotator is 2440X610X550mm with a net weight of 1.6T. You can use this roller to handle pressure vessels, boiler, chemical tools, storage tanks, and many other workpieces. These are also very suitable for your work if you have a high workload. You can rely on them to work fast and with adequate efficacy.

10 Tons conventional roller

The 60 Tons self-aligned roller

These self-aligned rollers are suitable for large cylindrical objects as they can easily handle 60 tons loads adequately along with a 750-4800mm workpiece. As its name itself says, you can adjust its wheel space via self-alignment. Also, welding rotators are widely used in boilers, chemical tools, oil and gases, shipyards, wind energy, and a lot more other workpieces. These are the best welding rollers for heavy-duty work activities.

60 ton conventional welding rotator

Conventional rotator

These conventional rotators are used in pressure vessels, boilers, and other essential workpieces. It has a variable rotation speed of the rollers from 100 to 1000 mm per minute. The wheels of rollers are covered with heavy and durable rubber that makes this machine more stable and sturdy. In these rotations, you can find the remote control box with a 12 m span that allows the adjustment in the speed of the rollers while on the go. So, with so many good things, rotators are the best option for your industry to reduce your hard work.

Conventional rotator

Pipe rotators for welding

These pipe rotators are specially designed to reduce labor costs by enhancing the overall productivity of your company. In these types of rotators, the welding head is fixed, and the piping spool moves with a particular speed. Thus, you can blindly count on these rotators for easy operation and reliable work performance while handling the workpieces.

Pipe rotators for welding

Self-aligning rotator

You can find the rotators an innovative welding tool as it contains the well-researched advanced technology on which you can mainly handle pipes, containers, boilers, pressure vessels, and many other cylindrical objects smoothly. In addition, welding rollers feature compact structure, small cubage, attractive shape, lightweight, etc. These self-aligned rollers enhance the quality of welding by improving the productivity of the company. Ultimately, you can get them for your industry to boost work performance.

Self-aligning rotator

These are all the welding rotators that can be used in any industry to enhance productivity and lead the company to a better profit ratio. You can find several companies that deal in them, and you can choose any one rotator according to the needs of the company workload.

For this purpose, Fengwei is the best company that provides all types of welding rotators and other equipment necessary for any company to grow with better productivity. In this company, 3200 plus machines are available, and more than 30 countries rely on this company to get their desired roller machines.

welding rotator

Also, the company offers all the machines with innovative technology that are made of the best quality. You can find these tools durable and sturdy that stay with your life.

Conclusion: As we know, rotators contain sturdy rollers that can rotate any cylindrical object in order to weld it perfectly. This Welding Rotator can be used to handle both tasks, whether it is light or heavy-duty. Also, they are used in boilers, containers, and many other cylindrical objects. You can use the rollers to handle large objects with more comfort and ease in order to make your rotating tasks smooth.

You can find many types in them, and you can get any rotator that suits your work profile. Many companies offer them and assure better quality and durability of the equipment. Hence, rollers are the best choice for any fabrication company to increase the productivity of the company so that you can enhance its conversion ratio comfortably.

PDF documents related to FENGWEI welding rotator:![]()

More about welding rotator

Adjustable Welding Rotator - Explosion-Proof & Anti-Channeling

The adjustable welding rotator consists of a driving frame and a driven frame as a set and generally does not need to make an installation foundation. The main and driven frames are made of steel plate structure brackets, and the main parts such as load-bearing shafts are made of high-quality steel, which has been quenched and tempered before being processed.

The mainframe and the driven frame each have two rollers, and the two rollers on the active frame are both synchronous driving wheels. The rollers are installed in the bearing housing assembly. The roller adopts the structure of the integral roller. The rubber roller adopts a polyurethane roller, which has a high bearing capacity and wears resistance and is not suitable for aging and degumming. It can be used for a long time without replacing the roller, which reduces maintenance costs and maintenance time, and has good performance.

The adjustable welding rotator adopts a manual screw to adjust the center distance of the rollers to meet the requirements of workpieces with different diameters and adapts to the rolling requirements of different diameter workpieces on the adjustable welding rotator. The parallelism of each axis of the main and driven frames is good, and the amount of movement is small. Installed in the roller assembly is a high-quality spherical roller bearing produced by a well-known domestic manufacturer. Using this bearing has a strong bearing capacity, and its self-aligning performance can reduce some elastic deformation during the bearing process, so that adjustable welding The rotator has a long service life, reduces maintenance costs and maintenance time, and has better performance. The grease used in the bearing is lithium-based grease, which has a good lubricating performance.

The imported Danfoss AV series inverter is used for step-less speed regulation, each parameter can be preset and digitally displayed, the speed regulation range is wide, the operation is stable, and it has multiple protections for overvoltage, overcurrent, overload, and overheating.

All the roller components on the master and driven adjustable welding rotator are symmetrically distributed to both sides according to the axis line of the roller bracket, and the heights of each roller are the same, to ensure the normal operation of the workpiece on the adjustable welding rotator. run. It is also equipped with a hoisting hook to easily hoist the adjustable welding rotator. The base is a box-type structure with a strong bearing capacity. Equipped with a long-distance hand-held operation box, which is simple and convenient to use, and can also be used with a manipulator to realize online operation.

The whole adjustable welding rotator has strong rigidity and stability, beautiful appearance, stable and reliable performance, simple maintenance, long service life, and low maintenance cost. The design and manufacture of the welding rotator are completely by the relevant provisions of the national "JB/T9187-1999" welding rotator industry technical standard and are designed and manufactured. In the manufacturing process, we strictly abide by the relevant standards in the quality assurance system of our company for production to ensure the production quality of the products.

Among the adjustable welding rotators, the anti-channeling adjustable welding rotator is sought after by various application industries. The main function of the anti-channeling adjustable welding rotator is to carry the workpiece and drive the workpiece to rotate for welding motion. The anti-channeling adjustable welding rotator adopts manual detection of the axial movement of the workpiece on the welding rotator and adopts two sets of manual lifting devices on the driven roller frame to adjust the workpiece offset by the roller lifting adjustment method. When it is detected that the axial movement of the workpiece exceeds the tracking range, the axial movement of the workpiece is adjusted by adjusting the lifting and lowering of the roller, so that the workpiece is in the correct working position.

Main features of anti-channeling adjustable welding rotator

1. The anti-channeling adjustable welding rotator consists of a driving wheel and a driven wheel, one main and one pair can carry the rated tonnage.

2. According to the different diameters of the workpieces, move the roller set, adjust the center distance of the rollers, and adapt to the diameter changes of the workpieces; the rollers are made of forged steel wheels, which have the large bearing capacity and strong driving ability to ensure normal use;

3. Welding parts are used for the base of the welding rotator, and the structural parts are annealed and reprocessed after welding to ensure long-term performance and service life; thus ensuring the strength of the base and overcoming the welding stress after long-term use. deformation.

4. The sliding surface of the base is finished, and the mounting and fixing holes of the wheel frame are designed. The holes at different positions are used to fix the wheel frame, and the center distance of the rollers is changed to adapt to the use requirements of different workpieces. Ensure that the wrapping angle of the two rollers to the cylinder is greater than 45 degrees, less than 110 degrees;

5. The positioning key with the base is designed on the wheel frame, and the positioning of the wheel frame is more accurate and reliable; after the center distance of the large-tonnage roller is adjusted in place, the key positioning is adopted, and the keyway processing adopts the simultaneous processing of the active and passive base to ensure that the center distance of the roller is accurate and at the same time. Safe to use.

Improve Weld Quality|Welding Rotator

A welding rotator is a kind of welding equipment that changes the position of the barrel weldment to complete mechanized and automatic welding. Sanding, painting, etc.

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding. It can be used in conjunction with automatic welding equipment to effectively improve weld quality, reduce labor intensity, and maximize work efficiency. It can also be used with manual welding. Use with other equipment.

Its outstanding feature is that in the whole welding process, only need to apply pressure, no need to fill any material, all welding methods do not need melting, so alloy elements will not burn like fusion welding, or harmful objects invade, welding rotator simplifies the whole welding process to maximize the hygiene of the welding environment.

The use of a welding rotator can maximize the quality of the welding seam, reduce the overall labor intensity and improve work efficiency.

The machine makes the welding seam in the most ideal position for welding through the rotating motion of the working wheel, and can be used together with the operating machine, welding power source, etc. to form an automatic welding center, which greatly improves the welding seam quality, reduces the labor intensity of the welder, and improves the Labor productivity, it is ideal equipment for welding various shafts, discs, simplified and other rotating parts.

Our company mass-produces welding rotators of various specifications, with reasonable design, convenient operation, and reliable quality, and undertakes the design and manufacture of special welding rotators.

1. The welding rotator can be combined arbitrarily according to the length and weight of the weldment, which is more flexible and convenient to use;

2. If it is within the specified range, the center distance of the roller can be adjusted automatically, which is more suitable for welding parts of various diameters, even the cylindrical welding parts are very stable;

3. It can drive DC electric power supply, complete the stepless speed regulation, and the welding speed range is large, the important thing is the speed stability;

4. The welding rotator has strong applicability and a wide range of overall use;

5. For the combined roller, the rubber is also wrapped outside the steel wheel, so the transmission is more stable, the friction force is greater, but the service life is longer;

6. The wheel pressure of the welding rotator is relatively small, which can avoid cold hardening of the working surface.

There are also high requirements when welding, and different effects need to be presented when welding different workpieces, to bring better effects to actual welding, and at the same time, it can also highlight more in actual welding. The advantages. Therefore, in this case, attention should be paid to the use of related equipment to make the welding effect better. For example, the use of a welding rotator is very good. This product can bring greater help to welding.

The welding rotator acts on the welding process of the workpiece, which can make the workpiece achieve better results during welding, and at the same time, it can also make the workpiece show a more efficient form during the welding process so that the workpiece can be welded. play a greater role. Therefore, the use of this product also needs to be viewed from many perspectives, especially the model of this product is also very important. If it does not meet the actual needs, it will also seriously affect the subsequent effects. It will also seriously affect the effect of subsequent welding.

At the same time, the use of a welding rotator should also master the relevant operation methods. This operation method is the most important. If the relevant methods are not mastered in the actual operation, it will also affect the daily use to a greater extent. Of course, this kind of product has already been done, as long as it is installed before use, and after installation, relevant debugging work must be done. This debugging is also very important, and good debugging can bring more benefits to subsequent use. Only good effects can play a greater role, which can also avoid the problems of subsequent use, so pay attention when using this product.

Performance characteristics of FENGWEI self-adjusting welding rotator

The welding rotator is suitable for the welding of circular cylinders. The distance between the rollers can be adjusted according to the size of the cylinder. There are various specifications of welding rotators for users to choose. Adjustable welding rotator has three types: manual screw adjustment, manual bolt shift and electric slide shift. By adjusting the center distance of the rollers, it is suitable for different diameter cylinders.

The driving frame and the driven frame respectively have four rollers, and the four rollers on the driving frame are synchronous driving wheels. The rollers are installed in the side panel assembly. The roller adopts an integral roller structure. The surface of the wheel is coated with high-quality rubber, which has high bearing capacity and wear resistance, and is not suitable for aging and degumming. It can be used for a long time without the need to replace the roller, which reduces the maintenance cost and time, and has good performance. The swing arm of the self-aligning roller frame adapts to the requirements of workpieces with different diameters. The clamping frame rotating shaft of the roller assembly has strong rigidity. When the workpiece is placed on the roller assembly, a good fit gap between the rotating shaft and its shaft hole can ensure that the fixture frame and the workpiece are opened at a suitable angle, so as to meet the rotation requirements of workpieces with different diameters. An oil groove is designed and manufactured on the rotating shaft, which can be frequently filled with grease to ensure its good lubrication.

Each shaft hole of the main and driven frame is processed by a card boring machine at one time, and the parallelism of each axis is good and the amount of movement is small. The roller assembly is installed with high-quality spherical roller bearings produced by domestic and international well-known enterprises and equipment manufacturers. The use of this bearing has an important bearing capacity and strong self-aligning performance. The elastic deformation in the welding rotator makes the welding rotator have a long service life, reduce the maintenance management cost and maintenance work time, and has a relatively good system performance. The grease used in the bearing is lithium-based grease, which has good lubricating performance.

The four rollers of the drive frame are fully meshed, and the drive gear is connected with the drive reducer with a "cross" coupling. All transmission gears are made of high-quality steel, with hardened tooth surfaces and lubricated with grease. It can be used for a long time without shifting. A gear cover is provided on the outside of the transmission gear.

Adopt imported inverter for stepless speed regulation, various parameters can be digitally preset and displayed, wide speed regulation range, stable operation, multiple protections for overvoltage, overcurrent, overload and overheating.

All the roller components on the master and driven welding rotator are distributed with symmetrical information from the axis line of the roller bracket to both sides at the same time, and the height development of each roller in the enterprise is consistent, so as to ensure that the workpiece can be processed normally on the welding rotator. operate efficiently. And equipped with a hoisting hook, the welding rotator can be easily hoisted as a whole.

The double cycloid reducer is used for double drive. The selected reducer and motor have relatively high synchronous system performance, so that the rollers on the welding rotator can run the enterprise synchronously. In addition, the use of cycloid reducer for innovative driving can prevent the impact of the reverse operation of the clamp frame on the reducer when students place a workpiece, and can effectively prevent the possible early damage of the reducer, so that the reducer and the motor can develop It has a long service life of the network. Large tonnage welding rotators generally use this type of transmission design.

Guidelines For Welding Rotator

Variety of welding rotator models is available for OEM. Conventional welding rotator,self aligning rotator,fit up welding rotator,sand blasting welding rotator for your choice. CE certified. Internationally recognized Fengwei Brand.

-

Features of various welding positioners

Through the rotation and flipping of the welding turntable, the workpiece welding seam is in the best welding position for welding or rotating welding with other equipment.

Welding Rotator -

How to choose Fengwei self-adjusting welding rotator?

The self-adjusting welding rotator is mainly composed of two sets of driving wheels and driven wheels. The rollers of the welding rotator adopt an internal iron core and external rubber structure, which have the characteristics of strong applicability, du

Welding Rotator -

Welding rotator speed setting method

For CNC cutting manufacturers, based on the research and development, manufacturing, and sales of welding rotator machinery and equipment for many years, it has been found that the setting of the initial heating speed for laser cutting has become a crucia

Welding Rotator -

How to use the welding rotator?

The welding rotator is mainly used in the equipment for the rotation of electric welding parts. It drives the welding parts to rotate by rotation.

Welding Rotator -

Welding rotator installation and maintenance guide

What is a welding rotator? It is a frictional ability achieved by the accessories, which can effectively ensure that the rollers are on the same axis for a long time.

Welding Rotator -

The welding process of the FENGWEI welding rotator

The welding process of the welding rotator must be checked one by one for the relevant steps in the welding process.

Welding Rotator -

Welding Rotator of Fengwei Ultra-high Technology

The welding rotator is mainly used for welding, polishing, lining, and assembling cylindrical cylinders. It can also be matched with another tooling, such as welding manipulators, welding positioners, etc. Assembly and welding of radial rotors.

Welding Rotator -

Pipe Welding Rotator

The pipe welding rotator consists of seven parts: machine base, driving device, column, cross arm, pressing device, column rotating mechanism, and remote control box. The cross arm can be lifted up and down electrically along the column guide rail and can

Welding Rotator -

Anti-channeling & explosion-proof welding rotator

The anti-channeling and explosion-proof welding rotator generally adopt two driving methods: DC speed regulation and AC frequency conversion speed regulation to achieve the smooth rotation of the weldment with step-less speed regulation.

Welding Rotator -

Welding rollers|self-adjusting, adjustable rotator

Welding rollers have a variety of styles, mainly to meet the welding needs of various specifications and irregular welding workpieces. The common ones are self-adjusting, adjustable, flat car, tiltable, and anti-axial movement.

Welding Rotator -

Turning Roller, rotator

The turning roller can drive the circular weldment to rotate through the friction between the weldment and the driving roller to complete the welding of the annular weld. The welding speed can be adjusted by the speed of the active roller on the Turning r

Welding Rotator -

Various types of welding rotator|Self-aligning, adjustable, anti-channeling

A welding rotator is a common electric welding auxiliary equipment, which is widely used in the welding process of various large cylinder equipment.

Welding Rotator