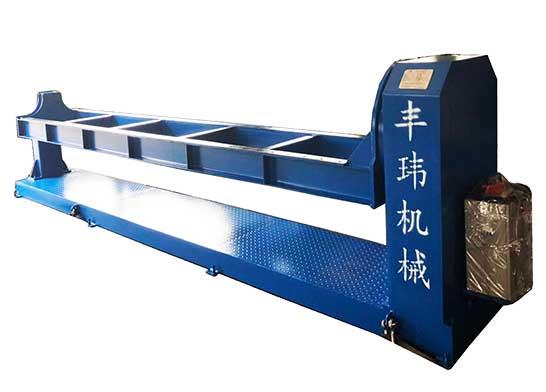

Head And Tail Stock Welding Positioner

Head and tail stock welding positioner is widely used in the fabrication field of wagons, carbody or metal frames. This type of welding positioner consists of 2 body sets on each side, which is a crab likewise to clamp the heavy-duty frame works between, fixed with clamping tools and ready to rotate in 360 degrees. In addition, you are free to add extra automation features. For instance, head and tail stock positioner is able to automtically elevate the position of work pieces in case too large or too high for fabrication. If the work frame is too long or too short, the welding positioner is also able to electrically walk along with rails and adjust the adjacent distance, which save manhour of adjustment between 2 body sets .

-

Loading Capacity (kg)

20 - 20,000 above

-

Application

Welding, Grinding, Sputter

The use of automation in welding allows for more incredible speed and precision while producing excellent welds. They also reduce the risk of making mistakes or producing inconsistent welds. This helps companies become more environmentally friendly and eliminate the need for jobs to be sent overseas.

There are several options for companies with limited budgets to rent or lease different types of welding equipment. Welding can be one of the most challenging in manufacturing processes. Both automated and manual welding offer distinct advantages. For many assemblies, manual fusion is still an ideal option. When quality is crucial, however, we recommend welding automation. It can also be used when soldering on multiple parts is required.

There are two types:

Semi-automatic and Fully-automatic welding automation.

Semi-automatic soldering is where parts are loaded into the soldering fixture manually. A welding control keeps the torch moving and the parts still at predetermined parameters. Once the fuse has been completed, the operator takes out the assembled parts and starts the next step. A Head and tail stock welding positioner machine or series of machines can load the workpiece, place it or torch it, and then complete the soldering process. The machine monitors the quality and unloads welded products. You can also design a series of quality checks into the machine. Semi-automatic systems can be beneficial for small companies that assemble products in small quantities but need to make sure welds are correct.

Automation is a great way to save time and money on welding.

Welding automation provides four distinct benefits. These include higher quality, greater productivity, lower labor costs, and reduced wastage. The combination of the mechanized torch, part motions, and electronic recall of parameters can improve quality. Automated soldering systems can outperform manual soldering with their high speed and quick setup times.

Positioners are the consequent portion of the automation system and literally have numerous uses in manufacturing companies.

- Welders should be protected at all costs

- Reduce fatigue

- Enhance the quality and productivity of your welders

- Different Positioner

Multiple weld positioning tools find practical usage in various sorts of industries. This robotic positioning equipment is some of the most popular in welding.

Manipulators: For extensive efficiency and fast delivery in welding tasks.

Turning Rolls – Used for stunning rotation of tanks, pressure vessels, and pipes.

You can save a lot of time by installing bed rollers.

Growing line systems - To activate vast diameter production, particularly in the wind tower manufacturing processes.

Welding Positioners

Individuals and companies often purchase a new welding station or rent one. This depends on the needs and budget of each individual. It doesn't matter if you rent or buy a Head and tail stock welding positioner; it is essential to consider these critical factors before spending money on the best.

When choosing welder positioners, COG (center of gravity) is crucial. It equally balances the welding on all axes. Because the welder applies more torque to the positioner, the COG can change due to the changing distances of the weldments. Other factors that can affect the COG include the addition of parts or materials to the positioner.

- The process of merging fixtures and welding with perfection varies depending upon your needs.

- The usage of Turning rolls are mainly for cylindrical products.

- Make sure that the equipment is mounted correctly to avoid tipping.

- We are wrapping ground current with welding positioners.

- Go for Rental Positioners

Renting the right positioners for welders is wise if you work in an industry that caters to the different needs of customers. It allows you to produce with a higher level of efficiency and less investment. In the present economic downturn, its one of the cost saving techniques in every company. Renting positioners is still a more economical option than buying them.

Stunning features of Headstock and Tailstock

- For long rotating welding

- Capacity rage: 5,000- 240,000Lb

- Fixed Base, Adjustable Basis, or Geared Elevation Models

- Gear-Safe Design

- Zero Maintenance Grounding Systems

- Merits of Headstock Tailstock Positioner

There are many applications for welding tailstocks and headstocks. There are three options available: fixed height, centerline, or power elevating models for the precise placement of weldments. These machines can be used either as a stand-alone machine or as a combination of many extensions and options, including the application of rail systems and support roles. One is a standard machine that can hold 500 to 50 tones, and another option is customized to meet your needs.

Why choose a Tailstock/Headstock over a Rotator

The vertical axis is all that a rotator spins. A rotator has no access to the bottom of the part or its textured side. Rotating around the horizontal direction - when combined with a custom fixture, an HSTS gives transparent access to the top, bottom, and front of the piece. The operator must position the welds correctly, access the torch quickly, and angle the torch appropriately to achieve a better welding application.

Head and tail stock welding positioner is widely used in the fabrication field of wagons, carbody or metal frames. This type of welding positioner consists of 2 body sets on each side, which is a crab likewise to clamp the heavy-duty frame works between, fixed with clamping tools and ready to rotate in 360 degrees. In addition, you are free to add extra automation features. For instance, head and tail stock positioner is able to automtically elevate the position of work pieces in case too large or too high for fabrication. If the work frame is too long or too short, the welding positioner is also able to electrically walk along with rails and adjust the adjacent distance, which save manhour of adjustment between 2 body sets .

A rotator won't offer the same flexibility. For all applications [inspection and assembly, cleaning, etc.], the part is rotated into a worker's envelope. This helps reduce ergonomic concerns, increases productivity, and improves uptime.

Applications

- Heavy Welding

- Robotic designing process

- Production Welding

- Laser Applications [Welding and Cutting]

- Component Assembly

- Cleaning

- Wagon industry

They are used to weld.LPG and Gas welders are available with different engines. This allows you to combine AC/DC welding. It can be used as an auxiliary power source for grinders and lights.

Positioners and manipulators:

There are many options for welding manipulators and tailstock positioners that offer better efficiency and safety. Headstock positioners can handle large, time-consuming pieces along a horizontal centerline.

These generators are engine-driven and can be used with natural gas, diesel, or dual fuel. A variety of specialty equipment is helpful for many purposes. Induction systems are highly efficient. They work on heating without the need for contact.

Renting Welding Machines has its advantages

- Equipment and other welder tools at lower costs

- Minimize the costs of machine repair and maintenance.

- Reduced freight cost, storage, handling, and other requirements

- Business growth is made possible by the use of innovative technology and welding processes.

- You don't have to pay additional fees for licensing or taxes.

Positioner Benefits

No matter how large the weldment is, it can reduce welder fatigue, increase safety, improve weld quality and save on production floor space. Workers don't have to be forced into unsafe or uncomfortably positioned positions by moving the assembly or weldment.

Welding Positioner

-

Introduction to welding positioner technology and mechanical principle

At this stage, the welding positioner sold on the sales market is mainly defined according to different production processes.

welding positioner -

Fengwei Welding Positioner|Quality Inspection Method

The use of welding positioners has been despised from the beginning, but with the diversification of welding workpieces, welding positioners have begun to get With everyone's attention, welding equipment manufacturers have also begun to continuously upgra

welding positioner -

How to buy welding positioner?

Welding positioners are important auxiliary equipment to assist in welding and are often used in conjunction with welding manipulators and welding robots.

Welding positioners -

Best selling welding positioner

Fengwei has more than 20 years of experience in the manufacture and design of welding positioners. The basic shapes of our commonly used welding positioners include outrigger type, tipping rotary type, and double-column single-rotation type.

welding positioner -

How to judge the quality of welding positioner

The development of domestic welding positioners in China has been quite mature and perfect. o is the structure of the welding positioner we purchased reasonably?

welding positioner -

Choice of Welding Positioner|Welding turntable manufacturer from China

The basic shapes of commonly used welding positioners are outrigger type, tipping rotary type, and double column single rotary type.

welding positioners