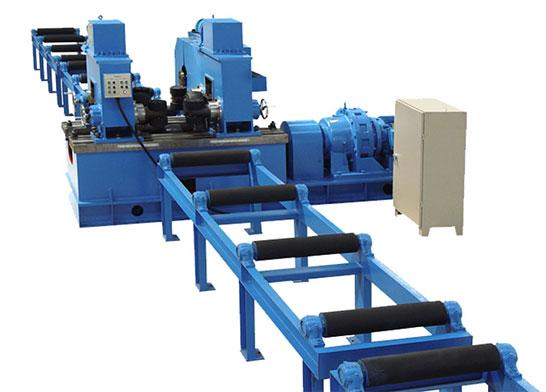

Beam Flange Straightening Machine

Compared with the traditional way of manual grinding and correction, this h-beam straightening machine effectively saves at least 50% of the labor cost and improves the work efficiency by at least 70%. There are 2 types of straitening which are Mechanical and Hydraulic for choice. How many times to go through the beam straightening machine is determined by the thickness of flange and the degree of the deformation. Normally, it takes about 3 to 5 passes. If the steel plate is thick and the deformation is small, the number of correction passes is less. If the steel plate is thin and the deformation is large, there will be more correction passes.

-

Applicable type:

H beams or i beams

Fengwei Machinery has developed and produced beam straightening machine over 20 years, providing customized straightening equipment for reshaping H beams or i beams after welding.

Why need beam straightening machine?

After beams are assembled and welded, they are often deformed and bent. In order to obtain a straight beam flange, h beams and i beams need to be leveled by a straightening machine.

H-Beam Flange Straitening Machine Features

- The main driving conveyor of beam straightening machine is driven by the motor through the cycloid pinwheel reducer. The cycloid reducer drives the main rotating wheel, thereby driving the beams to continuously complete the correction of the full length of flange.

- The main drive roller of beam straightening machine is made of 40Cr high-quality alloy steel, and the upper pressure roller is made of 35CrMo. The metal surface of beam straightening machine is subjected to high-frequency quenching and grinding, with a result of highly improved tolerance degree, wear resistance, and prolonged service life.

- Hydraulic pump station of beam straightening machine is an independent system Fengwei cooperates with well-known brands and assures superior quality.

H-Beam Flange Straitening Machine Application

Beam straightening machine is a special equipment for correcting the flange plate, with easy operation and high efficiency. It is widely used in metallurgical construction, steel structure for building construction, beam fabrication, hydraulic machinery and industrial installation industries.

H-Beam Flange Straitening Machine Maintenance:

1. Frequently check the joints of various moving parts and fixed parts of beam straightening machine. If any abnormal phenomena are found, tight it well.

2. Beam straightening machine can only correct the welding deformation of the flange plate, but cannot correct the verticality of the web and the flange plate.

3. During the operation of beam straightening machine, the pressing device must not be activated.

4. During the working process, no one should stand at the inlet and outlet of beam straightening machine to avoid H-beam collision.

5. The lifting and turning process of the work cannot be carried out on the track to prevent the beams from slipping and damaging the equipment.

6. The oil should be changed one month after the cycloid reducer is used for the first time. It will be replaced every six months in the future.

H beam production line

-

How to use the beam straightening machine?

The pressure frame of the beam straightening machine is a half-split structure, which can adjust the upper straightening roller set to compensate for the deformation of the upper frame and correct the wave shape of the steel plate.

beam straightening machine -

Manufacturing Process of Beam Straightening Machine

There are many process parameters of beam straightening machines, but most of the parameters related to mechanical design (such as roller diameter) are fixed and not adjustable.

beam straightening machine -

Powerful H-beam straightening machine

The H-beam straightening machine is used to straighten the deformed surface of the welded H-beam flange plate during the welding process.

H-beam straightening machine -

How To Adjust The Beam Straightening Machine?

The beam straightening machine changes the straightness by extruding rods, etc. Through straightening rollers. Generally, there are two rows of straightening rollers, and the number varies.

beam straightening machine -

The architecture of beam straightener machine

The frame of the beam straightening machine is a solid frame composite structure, which is a preloaded structure composed of a base, a column, an upper beam, a tie rod, and a nut.

Beam Straightening Machine -

Beam straightening machine manufacturer from China

The beam straightening machine is to change the straightness by extruding the bar on the straightening roller. A beam straightening machine is a kind of equipment for straightening pipes, wires, and metal profiles.

beam straightening machine