"

All the automatic welding machines that we order from Fengwei are

very efficient and reliable. Comparing to other wind tower processing

equipment manufacturers, Fengwei is more durable. We ordered our

first welding machine from fengwei five years ago, and every time when

we expend our production, we select Fengwei as our equipment supplier

because of it professional technical team and satisfied after-sales

services.

"

- Mr.Shariq

In the present world, the environmental industry is given much priority by many counties. It is to make use of a renewable source of energy and environmental protection. The developed economies in Europe and the USA have implemented them. These countries are free from environmental pollution, save perishable fuels and save on building plants and machinery. When it comes to the environmental sector, its allied service industries are helping a lot in building sewage-related infrastructure, wind power towers. Here, such infrastructures are robust due to the advanced welding technology. Here, we have discussed a few of them.

Wind Power and Allied Ancillary Services

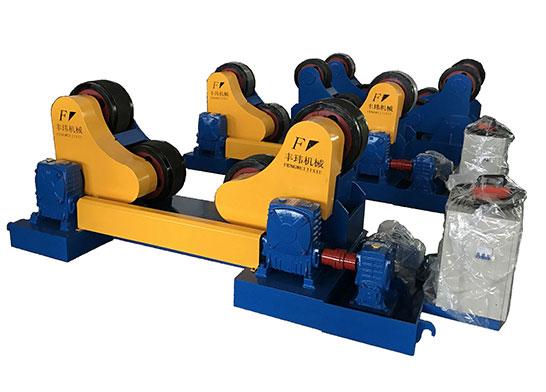

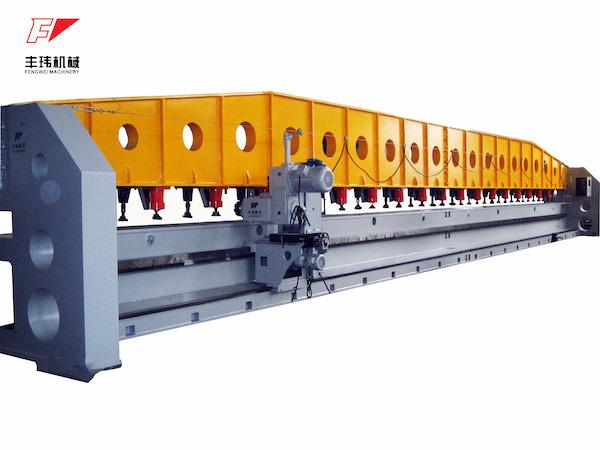

Wind towers have saved 30% of nonrenewable energy while producing electricity. Today, there are hundreds of wind farms and sea areas are having thousands of wind towers. They hold the generator or dynamo blades, which are tones of weight. These wind power infrastructures are standing strong due to the use of welding rotators, welding manipulator, and welding positioners to be a tank assembly line. Experts in technology and engineering make them.

Welding Technology for Wind Power Manufacturer

Wind towers are the need for developing economies today. Yet, they lack technology such that they are unable to manufacture within their countries limit. Today, it is easy to buy the latest wind power production line welding equipment and accessories online. The only need to import is the turbine. The rest of the parts can be manufactured internally. Thus, a wind tower must be strong enough to withstand heavy winds. It is advisable to follow the best practice in labor safety, environmental sector best practices, and people’s safety.

Wind tower assembling needs many welding areas to fix by the tones of steel in precision.

Advanced welding machines for wind towers are the only solution to assemble them as per environment industry standards.

Wind towers will last long any catastrophic events if assembled with certified welders, welding equipment, and accessories.

Assembling such a colossal tower needs manual and semiautomatic welding from the base to the top of the wind tower.

Industrial welding machines and equipment are necessary apart from high-grade screws and bolts.

The developed countries like the USA and UK have already made many wind power towers in farms and high wind flowing areas. They use the power source to provide electricity to households, farms, and small-scale industries. They produce in Megawatts such that wind power farms are the best to supply current to a whole community in the future. The developing countries must follow this environmental concern and make environment-friendly power sources. Here, the wind towers contribute as a one-time investment and long-term energy and savings for people and the nation.

Increasing numbers of wind tower manufacturers reached us for automatic welding machine consultation of assembly line. We helped to offer the customized field machine layout from first step of single tank fabrication to the end of all tanks’ alignment. For a quick note, In which, conventional welding rotator and welding manipulator is a good partner to automatically complete the weldment of circumferential seam. Fit up welding rotator, also known as hydraulic welding rotator, is a must have in the wind tower production line to assist on aligning the seams between adjacent cylinders. When the length of tanks after weldment is increasing, the fit up welding rotator also helps to transfer tanks to other sets of welding rotator and automatically move away to leave the space of alignment.

Energy from wind or renewable energy is the future for all economies in the future. It is advisable to implement them today for a better tomorrow. It is how the developed countries have saved a lot on energy production.

Nuclear Energy and Production Line

A hydro generation nuclear reactor reduces a lot of pollution while producing electricity. Thus, it is an environmental-friendly technology, which is the need of the hour for every country in this world. Such manufacturing units need welding rotators, welding manipulator, and an advanced welding system, which is CNC, controlled.

Today, the production of such reactors is limited to developing countries. It is due to the lack of welding technology and the availability of ancillary parts. Thus, they can import technology and assemble it in their country. It is the best way to build a hydro generation nuclear reactor in your country. It will produce megawatts of electricity and save the environment from air pollution caused due to other forms of power generation plants like thermal power plants.

It needs a strong steel pipeline to carry water, gasses, and oil. Thus, high precision and strong welding are necessary for pipelines and oxygen storage tanks. When in the process of fabrication, welding rotator and welding manipulator significantly help to increase the quality of seam weldment and boost the efficiency of production output. The environmental industry is focusing on environmental safety for the workers working in such reactors. Thus, they do take utmost care in the environment where they are present. This sector gives importance to safety first, security, and economy for running such plants. When it comes to manufacturing this machinery, it is advisable to use the environment industry-approved welding machines, tools, and accessories.

Waste Control and Infrastructure Facilities

A sewage tank and the septic tank are essential for every economy. The developed countries use tanks made of metals for longevity and protection from sewage leakages. Thus, it will not pollute the groundwater and air. The developed countries use metal-based tanks, which are assembled through heavy-duty welding technology and equipment, especially fit-up welding rotators and welding manipulators.

Metal tanks need strong welding on all sides such that no leakage will happen in the future.

Metal tanks needs high-grade welders and a welding machine.

A semiautomatic welding technology is the best for manufacturing in bulk quantities.

Certified welders can import welding technology after getting proper training and certification locally.

The developing economies must build such civic infrastructure to save the environment. Thus, they need to import advanced welding rotators and welding manipulators. It comprises welding equipment, devices, and accessories.

The use of metal sewage and septic tanks is healthier than conventional tanks in homes and commercial places. They are easy to connect with any type of piping materials, fixtures, and accessories. They are affordable than the building of the traditional tank. You can keep them under the ground and over the ground. They do not emit bad smell when over the ground. It will be much convenient to dispose of them by using a carriage. Some models of welding rotator and welding manipulator are also very applicable and must have for the process of fabricating sewage tanks.

The environmental industry is developing to curb pollution, save energy and reduce the cost of nonrenewable energy productions. Thus, the advancement in welding technology has made the environment sector make new plants, machinery, and infrastructure last long due to its welding bonding. Today, welding technology is the need of the hour to build such infrastructure for the public and related industries. So now you have grabed a lot more information. Thus, you can import welding machinery, equipment, welding accessories, and tools in your country by online purchase.