Anti-Explosion Welding Rotator

Welding rotator with explosion-proof features, as its name suggests, is a special welding rotator designed with explosion-proof device. It is also one of popular welding automations. With same function of adjustable welding rotator and self-aligend welding rotator, anti-explosion welding rotator brings convenience and automation to the fabrication process of cylinder objects, expecially used as a special coating auxiliary equipment in the painting or coating process.

-

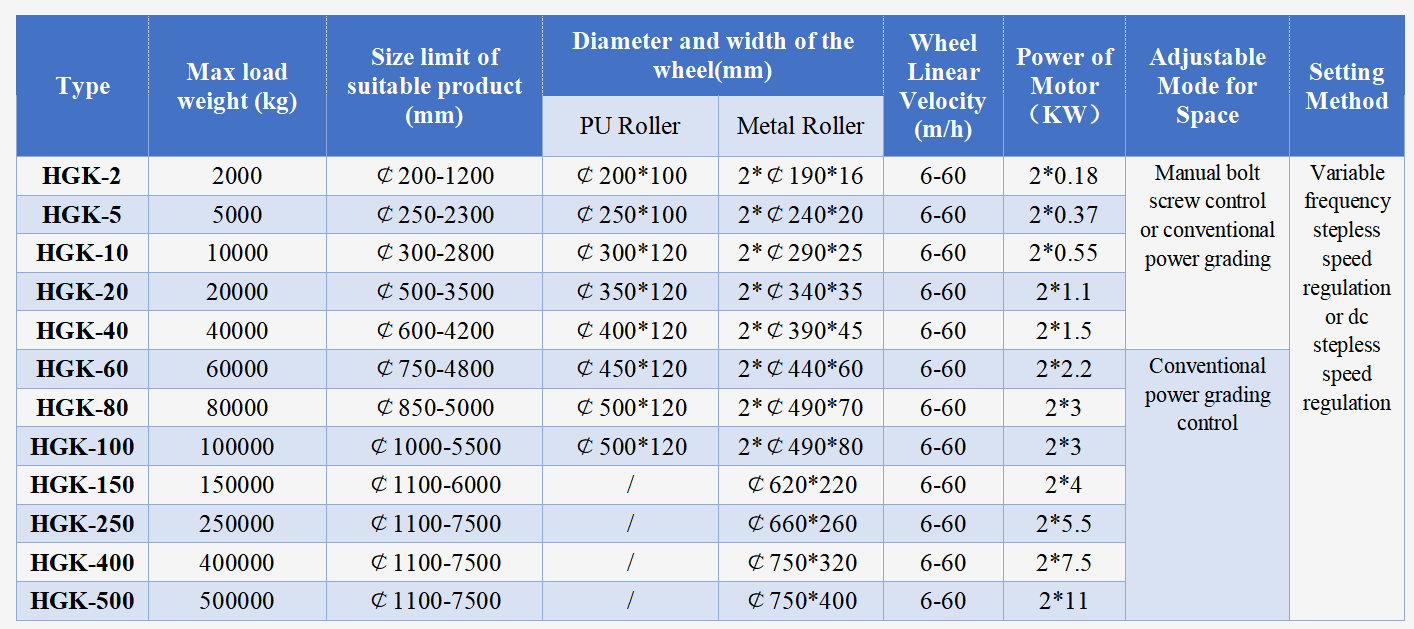

Model

Adjustable\Self-aligned\Fit up\Growing line

-

Loading Capacity (kg)

1,000 - 3,000,000 above

Why do I need to purchase an explosion-proof roller frame?

Clients who purchase explosion-proof welding rotator are mainly used in painting booths to automatically rotate the cylinder while painting by the staff . On the one hand, welding rotator with anti-explosion function increase time efficiency to move around tanks by using cranes and reduce labour quantity at least from 2 to 1 to complete the full range of paint spray flow alone.

More importantly, the explosion-proof welding rotator has a high level of safety, strong protection, and can adapt to special working environments. Usually the IP rating is above 54.

When spraying, whether it is powder spraying or painting, it must be atomized to ensure uniformity. The composition of the paint is all chemical substances, and the paint mist and other volatilized gases are flammable. The spraying job site is like a gasoline station, which is flammable and explosive. The welding rotator is electrically controlled, and if it is not properly protected, it will cause a fire and explosion.

Therefore, in spraying projects, international standards require to use explosion-proof welding rotator. The common application of explosion-proof welding rotator is also in spraying projects, so spray welding rotator are often named as explosion-proof welding rotator.

How to choose a suitable explosion-proof roller frame?

The explosion-proof welding rotator consists an explosion-proof motor, and an explosion-proof electric control box, etc., so that it can be used in a sensitive working field.

Fengwei has always used certified explosion-proof motors and electric control cabinet. If the welding rotator you buy is equipped with a general motor and electric cabinet, you may take price advantage but the safety is not guaranteed. Simple welding rotator will cause gas explosion or fire accidents in the flammable and explosive chemical gases and combustible dust particles. The explosion-proof welding rotator can effectively improve the safety and efficiency from the root, importantly save trouble cost in the future.

How to recognize the anti-explosion welding rotator?

Here is the feature of anti-explosion cabinet equipped in welding rotator. The cabinet has double-layer structure with 1.2mm high-quality cold-rolled steel plate, phosphating treatment, epoxy resin spraying, and high temperature curing. The bottom is designed with anti-leakage threshold, which can retain the leaking liquid. Both inside and outside of the cabinet are passivated by phosphoric acid, epoxy resin, to maintain a high finish and to minimize the effects of corrosion, moisture and ultraviolet rays.

The explosion-proof roller frame is mainly suitable for explosive and flammable environments, such as the spraying project of the barrel.Widely used in industries including wind power, pressure vessel, petrochemical, pipeline, steel structure, boiler, shipbuilding, welding repair industry and so on.

Welding Rotator

The whole welding rotator has strong rigidity and stability, beautiful appearance, reliable performance, simple maintenance and long service life. Learn more about the details and types of welding rotators.

-

Self-adjusting Welding rotator|Safety Operation Guide

Fengwei has 20 years of experience in the design and development of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world.

self-adjusting welding rotator -

welding rotator|US hot sale

Fengwei is a professional in the manufacture and research and development of welding rotators. Various types of welding rotators have been recognized in the welding application fields of various large-scale equipment in the United States.

welding rotators -

Welding Roller | Welding rotator manufacturer

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators.

Welding rollers -

The Best Quality Self Adjusting Welding Rotator From China

Self-adjusting welding rotator is a kind of equipment used with a welding manipulator, which is used to support or drive rotation when welding straight seams and circumferential seams of pressure vessels and large-diameter pipes.

Self-adjusting welding rotator -

Improve Weld Quality|Welding Rotator

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding.

welding rotator -

Adjustable Welding Rotator - Explosion-Proof & Anti-Channeling

The adjustable welding rotator consists of a driving frame and a driven frame as a set and generally does not need to make an installation foundation.

welding rotator