Beam Welding Machine

The H-shaped steel welding equipment is suitable for the design, selection, production and acceptance of all kinds of welded H-shaped steel components. The welded h-shaped steel is also suitable for steel structure rods, beams, piles, industrial frames and other components. So beam welding machine is widely used in the steel structure construction industry. If with limited space, integrated assembly, welding and straightening machine is more recommended.

-

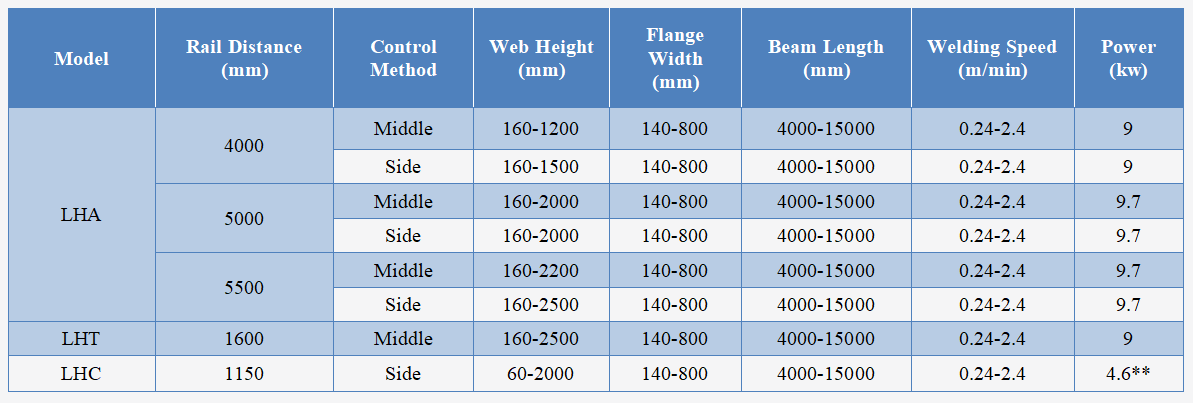

Type

LHA gantry type,LHT beam,LHC cantilever type

The H-shaped steel welding equipment is named after the H-shaped section due to the welding process. Beam welding machine designed by Fengwei Machinery consists of 3 categories: LHA gantry type beam welding machine, LHT beam welding machine with double column and LHC cantilever type beam welding machine.

All of beam welding machine adopts A.C. variable frequency control to realize back and forth movement. All 3 models of beam welding machine have stable and reliable operation, as shown below in picture.

LHA Gantry-type Beam Welding Machine

LHT Beam Welding Machine with Double Column

LHC Cantilever Beam Welding Machine

The welding methods equipped with beam welding machine include submerged arc welding of h-shaped steel and high-frequency welding of h-shaped steel. Through a continuously high-speed production and mechanical automation by beam welding machine, H-shaped steel is realized with high rigidity of section moment, section coefficient and pressure resistance, as well as higher load-bearing capacity than those of hot-rolled steel with the same unit weight.

Beam welding machine is used to weld steel plates into h-shaped structure, and has the ability to continuously weld and assembly H-shaped steel if paring with other beam production line such as beam assembly and beam straightening machine. The mechanical structure of beam welding machine is as following:

Ø There are multiple sets of web support positioning devices installed in the main body of the beam welding machine, and flange pressing rollers are installed on both sides of frame. Such structure design effectively ensures the centering accuracy and stability of the web and flange in welding.

Ø There is a welding seam tracking device adopts in the beam welding machine, with electric up and down adjustment and positioning mode. No need to adjust welding wire angle with convenient positioning of wire.

Ø If grouping light weighted h-shaped steel beam, using single-arc double-wire welding in submerged arc welding can realize high-speed flat-angle welding.

Ø The operation buttons and the control box of the welding machine are integrated on the welding operation panel to realize overall easy operation.

Ø Multi-point grounding method of electricity effectively guarantees the stable current during welding.

Ø The conveying and welding speed can be switched arbitrarily, which greatly improves the production efficiency of H-shaped steel.

Ø The high-power flux recovery machine can effectively recover and recycle the flux after welding.

Ø The above is the one of configuration for your reference, the final version will be customized according to the workpiece parameters. Beam welding machine can be processed, designed and combined arbitrarily with the project, and special specifications can be manufactured to meet the actual needs of special projects.