T/H beam assembly machine

Series Z18 of beam assembly machine is used for assembling T/H and other shaped steel structure, with high degree of automation and good precision, which greatly reduces the labor intensity.

-

Design method

segmented

-

Optional

automatic spot welding or manual spot welding

-

Applicable beam

T、H、I、tapered

The beam assembly machine has the option to equip with either automatic spot welding or manual spot welding. When using automatic spot welding, the operator can adjust the speed rhythm of automatic spot welding as needed, and the rhythm of automatic spot welding is adjusted by the main roller conveying speed and spot welding interval. If manual spot welding, the operator needs to prepare gas shielded welding equipment on your own.

Before puchasing, you may have a few questions about the machine and us. Check below if answer your concerns.

Is Beam Asssembly Machine a fully-automatic machine?

Before going through assembly procedure, the operator needs to load heavy structural parts to the conveyor rollers by using overhead cranes with safety and efficiency. Once loaded both flange and web on the feeder rolls, you can leave the rest job to the beam assembly machine by operating the control panel.

The conveyors of this machine adopts a segmented design and is divided into 6 sections, with 3 sections in the front and another 3 sections on the rear (1 main and 2 passive). The driving roller is connected with the main machine through the chain to realize the synchronization. There are adjustable height stand at the bottom of the conveyor, which can easily adjust the height of the conveyor.

What are the steps to assemble a h beam by a beam assembly machine?

There are 2 main parts divided into 6 mic-steps handled by the beam assembly machine to joint the flange and web.

Part 1: T-shaped assembly

1) Load the finished flange and web sections from CNC Cutter onto the input conveyor by the overhead crane, and start the trolley box at the same time to make them initially aligned.

2) Start the driver roller out of 3 sections, and transport the initially aligned flange and web forward until the end faces are aligned with the stopper, and manually lift the stopper to align the ends of the flange and web.

3) Once aligned, the upper wheel presses the edge of the web through the upper pressing cylinder.

4) Then the flange is pressed to the web by that hydraulic jacking roller lifts the jacking roller through the hydraulic cylinder, to closely combine the flange and the web.

5) At this time, start manual spot welding or automatic spot welding while continuously transfering the T beam forward until all spot welding is completed.

Part 2: H-beam assembly

Return the assembled T-shaped steel to the input conveyor and place another flange plate, repeat steps on part 1. After all the spot welding is completed, the assembly of the H-beam is also completed so far.

What types of beam can be assembled by the beam assembly machine?

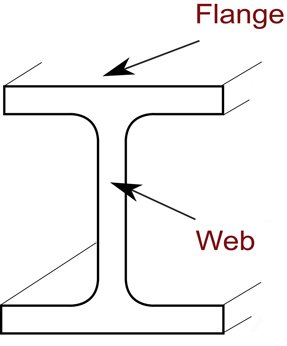

T Beam: T beam is a specially designed load-bearing structure of reinfored concrete or metal, widely used in construction. It is assembled by one flange section and a web section, as the first step to assemble h beam.

H Beam: H beam has a symmetrical shape with same sized flange attached on the side of web. Repeated the same assembly step as joint T beam to complete the other side of flange joint.

Tapered Beam: Tapered beam has two unequal-sized flange sections linked by a web section. One flange is shorter than the other-sided flange. This type of dissymetrical h beam has high stiffness-to-mass ratio, and is also applicable to be assembled by the beam assembly machine.

I Beam: I beam has shorter flange than that of h beam but similar shape. So assembly I beam has the same assembly procedure as H beam.

What are the others related machines to group as a full automatic beam production line ?

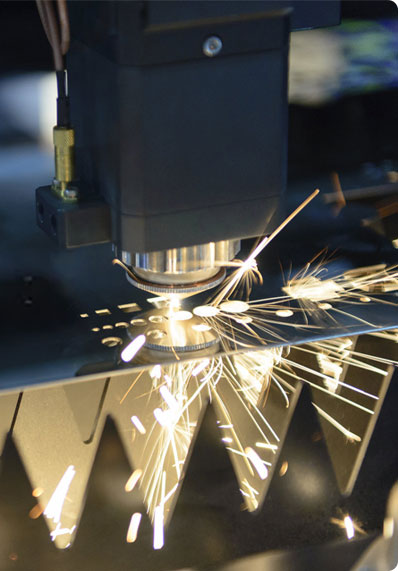

CNC Flame or Plasma Cutter: cut metal sheets to individual flange and web sections

Beam Assembly Machine: used to assembly flange with web.

Beam Welding Machine: weld the seam between flange and web after spot weldment.

Beam Flange Straightening Machine: straighten the heat deformation of flange sections after weldment.

|

Model |

Z18 |

|

|

Web Size |

Height (mm) |

200-1800 |

|

Thickness (mm) |

6-32 |

|

|

Length (mm) |

2000-15000 |

|

|

Flange Plate Size |

Width (mm) |

200-800 |

|

Thickness (mm) |

6-40 |

|

|

Length (mm) |

4000-15000 |

|

|

Assembling Speed |

(m/min) |

0.5-6 |

H beam production line

-

H-beam production line-horizontal

The traditional H-beam production line is mainly vertical, while horizontal production greatly improves the production of lightweight H-beam. It also has the characteristics of small welding deformation.

H-beam production line -

Welding instructions for H-beam production line

Relevant instructions for the H-beam production line, including: production process, main welding automation equipment, production specifications, process characteristics of the production line, etc.

H-beam production line -

Welding automation equipment required for H-beam production

for H-beams, the casting process requires multiple steps, and each step requires welding automation equipment. So what is needed?

H-beams -

FengWei H-beam production line

H-beam steel is the most used steel structure for the installation and configuration of steel structures. So what machines are needed to produce H-beam steel?

h-beam production line