H-beam production line

The traditional H-beam production line is mainly vertical, while horizontal production greatly improves the production of lightweight H-beam. It also has the characteristics of small welding deformation.

The traditional H-beam production line is mainly vertical, while horizontal production greatly improves the production of lightweight H-beam. It also has the characteristics of small welding deformation.

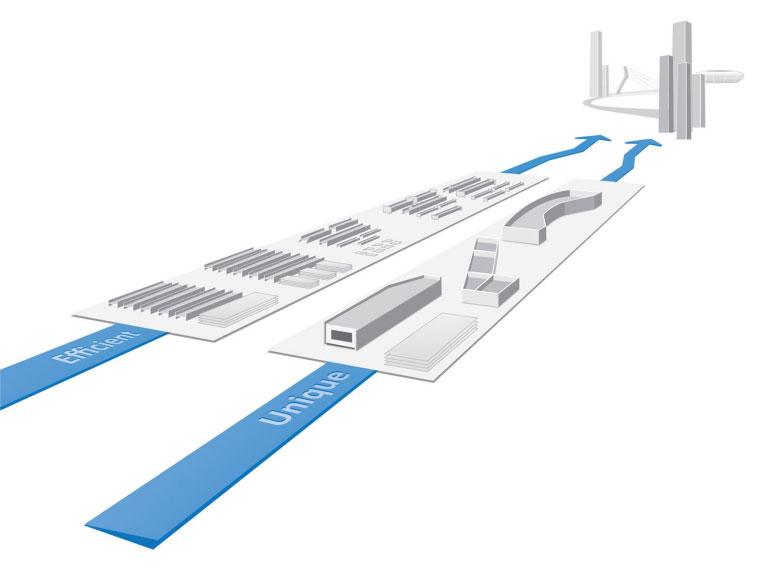

The production efficiency of H-beam has always been one of the focuses of the factory, especially for some conventional or ordinary production equipment, the upgrade of equipment is indispensable, and with the needs of a large number of factories, horizontal H-beam production lines It has become the main force of the new generation. Under the effect of all welding automation production, it can be assembled into H-shaped steel after the steel plate is assembled, and a complete welding automation production line is formed under the action of the welding machine.

H-beam production lines

The traditional H-beam production line is mainly vertical, while horizontal production greatly improves the production of lightweight H-beam. It also has the characteristics of small welding deformation. It is widely used in steel structure and construction industries, and it is consistent. Won the praise of the industry. As an excellent manufacturer of welding automation equipment, Fengwei is specialized in the manufacture of horizontal H-beam production lines. It not only upgrades the original equipment and improves safety measures, but also increases diversity in terms of functions.

Assembling machine

Our horizontal H-beam production line adopts horizontal assembly and can weld two longitudinal seams at the same time. While using, the welder only needs to simply weld the front-end positions of the H-beam wing plate and web plate firmly. It can solve the problems of the assembly of H-section steel and the welding of two longitudinal seams at one time, which greatly improves the welding efficiency of the factory. Not only that, it can also weld some difficult problems, such as some oblique angles that are not high. On the other hand, it can be solved with ease.

The entire production line mainly adopts this high-efficiency single-arc double-wire welding process. In terms of welding speed, it perfectly solves the problem of slow forming speed, so that many factories in the industry pay more attention to it, breaking the original traditional ship-shaped welding. Disadvantages, so as to achieve flat-angle welding.

Production process of H-beam production line

1. The production line is a simple production process in which three steel plates pass through one assembly to form an H-shape and pass through the welding correction of two welds.

2. During the welding process, no auxiliary equipment such as crane hoisting, chain turning machine and conveying roller table are needed, and the welding is completely integrated and automated.

3. It only needs to be lifted by crane for cutting and blanking and wing plate correction, and no crane lifting is required for other aspects, and it can be completed after two weldings.

H-beam straightening machine

How good is the finished output of the H-beam production line? A single production line can produce nearly 10,000 tons within a year, so it can be said to be the leader of the H-beam production line.

Fengwei welding automation equipment manufacturer is a trustworthy partner. Based on the horizontal production line of the H-beam production line, we have carried out many upgrades and transformations. Not only the operation is simple in the production activities, the automation level is high, but also the perfect To ensure the quality of the workpiece. While the welder is operating the machine, it will also greatly avoid the harm caused by the entire welding process radiation to the welder, the performance is stable and long-lasting, and the maintenance is very simple.