Polyurethane Roller

Polyurethane Roller(PU Roller) is used in various industries for its high wear resistance, high bearing capacity, and excellent tear resistance. Equipped with our welding rotator, imported polyurethane material is officially used to coat the roller. Polyurethane roller has the characteristics of high strength, compression resistance, wear resistance, oil resistance, acid and alkali resistance, corrosion resistance, tear resistance, impact resistance, a wide range of hardness, firm adhesion with metal, and no degumming.

Polyurethane Roller(PU Roller) is used in various industries for its high wear resistance, high bearing capacity, and excellent tear resistance. Equipped with our welding rotator, imported polyurethane material is officially used to coat the roller. Polyurethane roller has the characteristics of high strength, compression resistance, wear resistance, oil resistance, acid and alkali resistance, corrosion resistance, tear resistance, impact resistance, a wide range of hardness, firm adhesion with metal, and no degumming. Polyurethane has good properties such as high load-bearing, shock absorption, and cushioning, can have good adhesion with metal, and has a wide hardness range. Therefore, the rubber roller is gradually replaced by a polyurethane roller and is widely used in welding rotators.

How is the polyurethane roller of the welding rotator manufactured?

Polyurethane rollers are generally made of vulcanized natural rubber, synthetic rubber, gelatin, polyurethane, and other polymers. When making, it is necessary to ensure the composition percentage and heat degree to stabilize the hardness and components. The colloid is uniform and free of impurities through filtration. This is particularly important for polyurethane rollers. In high-speed operation, the force is uniform and the energy transfer is uniform. When expansion or contraction is caused by various factors, it can still be uniform. In this way, only adjustment can reduce or avoid adverse effects.

By heating, pressurizing, and vulcanizing, it is stabilized to reduce the shrinkage of rubber to a smaller extent under external force. The soft and malleable compound is turned into a solid material with a certain softness, which is more suitable for the transmission and transfer of ink.

The key to determining the dimensional accuracy and surface area of cots is especially the radian treatment of alcohol-water roller. The rubber surface looks smooth, but there are many small bulges and depressions under the high-power magnifying glass. These convex and concave parts increase the surface area of the cot, making it have superior ink transfer and transfer performance.

How to install polyurethane on the roller of the welding rotator?

Press the roller of the welding rotator together with the tension bearing and drive it through the friction between the two rollers. If the belt needs to be replaced, the operator can hold the handle above the eccentric wheel, rotate the shaft, rotate the wheel, and push the connecting rod roller to rotate, so as to separate the roller of the roller carrier from the polyurethane and successfully replace the new ribbon roller.

As the polyurethane roller of the welding rotator, industry glue is the key factor of the production process. If there is no formula, the rubber material itself and its formula should be very clear. In the production process, it is difficult to have some quality problems affecting the whole production process. Therefore, on the production side, we must first be familiar with the materials used in polyurethane and their mixed formula, Therefore, in the general production process, the rolling process of the roller frame is very high, and some rollers with different properties and materials can be produced.

Fengwei Machinery provides complete customized solutions.

The construction, selection, and manufacture of welding rotators and rollers of various specifications comply with CE standards. Regularly check all production steps and use only certified materials and accessories, first-class motors, and reducers to ensure the best quality standards of our products. High-grade manufacturing accuracy.

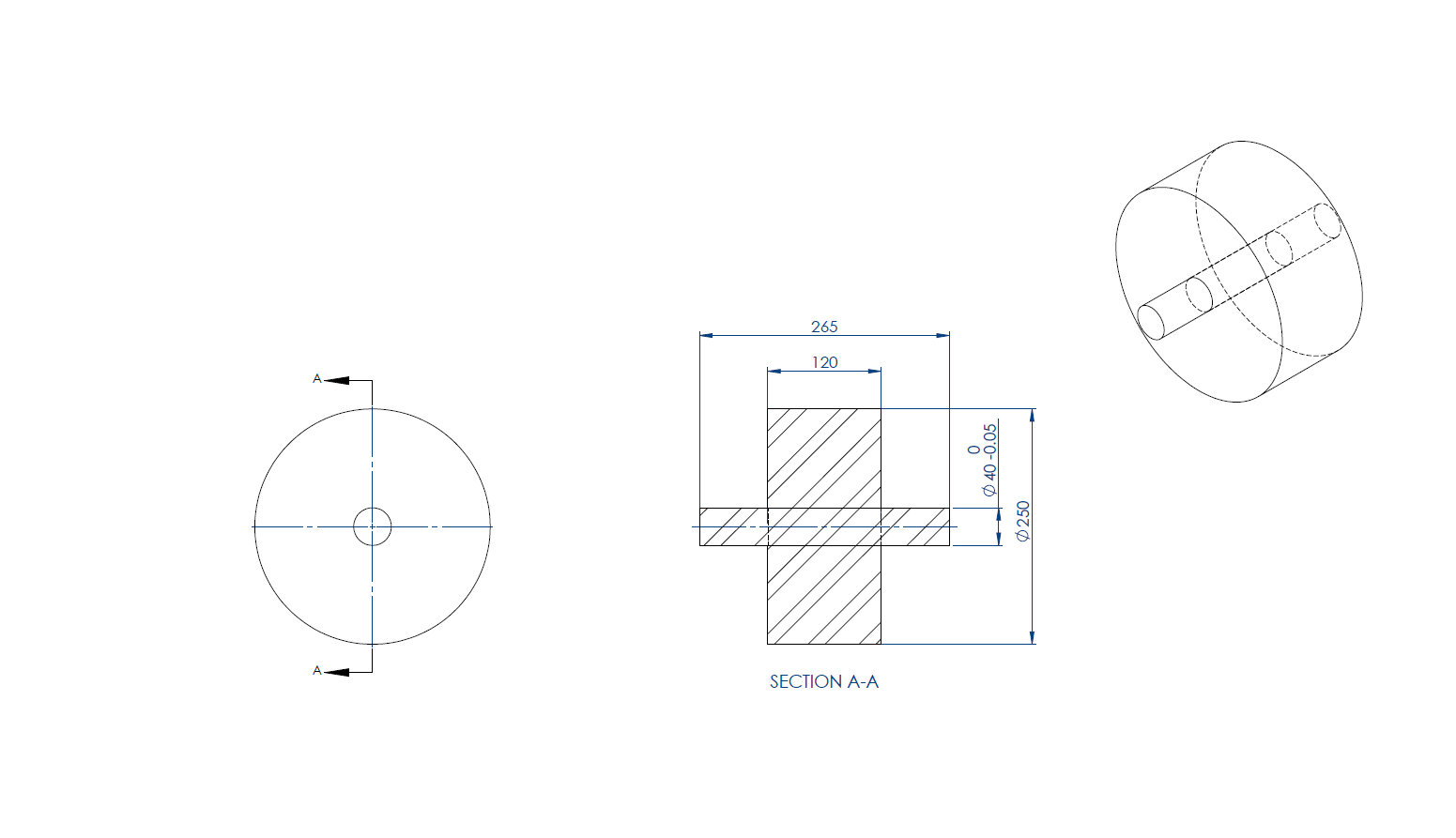

Please kindly measure LETTER MARKED data for precise quotation, which are?

- A = roller width with protruding length

- B = roller width

- C = internal circle diamter

- D = roller diamter

- Amounts of shafts, if needed

- Dimension of shaft

- Optional for rubber or PU coating welding rotator, or metal roller.

Once received, we will offer quotation and roller layout for confirmation.

|

Type |

Max load weight(kg) |

Diameter and width of the wheel(mm) |

|

PU rollers(mm) |

||

|

HGK-2 |

2000 |

Ф200×Ф40×100 |

|

HGK-5 |

5000 |

Ф250×Ф50×120 |

|

HGK-10 |

10000 |

Ф300×Ф60×130 |

|

HGK-20 |

20000 |

Ф350×Ф70×180 |

|

HGK-40 |

40000 |

Ф400×Ф70×220 |

|

HGK-60 |

60000 |

Ф450×Ф80×280 |

|

HGK-80 |

80000 |

Ф500×Ф100×180×2 |

|

HGK-100 |

100000 |

Ф500×Ф100×200×2 |

|

Type |

Max load weight(kg) |

Diameter and width of the wheel(mm) |

|

PU rollers(mm) |

||

|

HGZ-2 |

2000 |

Ф200×Ф40×80 |

|

HGZ-5 |

5000 |

Ф250×Ф40×100 |

|

HGZ-10 |

10000 |

Ф300×Ф50×120 |

|

HGZ-20 |

20000 |

Ф350×Ф60×150 |

|

HGZ-40 |

40000 |

Ф400×Ф70×160 |

|

HGZ-60 |

60000 |

Ф450×Ф80×180 |

|

HGZ-80 |

80000 |

Ф500×Ф100×200 |

|

HGZ-100 |

100000 |

Ф500×Ф100×240 |

Welding Rotator

The whole welding rotator has strong rigidity and stability, beautiful appearance, reliable performance, simple maintenance and long service life. Learn more about the details and types of welding rotators.

-

Self-adjusting Welding rotator|Safety Operation Guide

Fengwei has 20 years of experience in the design and development of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world.

self-adjusting welding rotator -

welding rotator|US hot sale

Fengwei is a professional in the manufacture and research and development of welding rotators. Various types of welding rotators have been recognized in the welding application fields of various large-scale equipment in the United States.

welding rotators -

Welding Roller | Welding rotator manufacturer

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators.

Welding rollers -

The Best Quality Self Adjusting Welding Rotator From China

Self-adjusting welding rotator is a kind of equipment used with a welding manipulator, which is used to support or drive rotation when welding straight seams and circumferential seams of pressure vessels and large-diameter pipes.

Self-adjusting welding rotator -

Improve Weld Quality|Welding Rotator

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding.

welding rotator -

Adjustable Welding Rotator - Explosion-Proof & Anti-Channeling

The adjustable welding rotator consists of a driving frame and a driven frame as a set and generally does not need to make an installation foundation.

welding rotator