"

Fengwei is a good business partner. their team are not only professional

but also efficient. We have ordered three batches of roller bed and

welding positioner for light poles. Delivered the equipment with satisfied

quality and quantity. In addition, every time we encounter problems,

their technicians can make on-site debugging and provide technical

support for the problems in the first time.

"

- Ms. Bianca

Steel tower poles is the most common supporting structure of overhead transmission lines, and it is an important component of the infrastructure in the fields of electric power, communication and transportation, mainly as steel structure, replacing wood structure or reinforced concrete structure. With the rapid development of Chinese economy and the continuous expansion of the scale of infrastructure construction, the tower industry is developing rapidly, and the scale of relative enterprises have also been increasing with the market demand.

The electricity steel rod is made of polygonal steel pipe or round steel pipe, and treated with anti-corrosion coating on the surface of hot-dip galvanized or hot-spray zinc (and zinc alloy) steel pipe. Ordinary power pole tower, with the characteristics of material saving and large bearing capacity, is eligible under the national macro policy of resource saving and environmental protection, and will be widely used in the future uHV engineering construction. In addition, some special electric poles, such as anti-corrosion poles, wireless communication base station poles, oil field poles, wind power poles, photovoltaic power generation foundation poles and railway poles, will also be widely used in the future.

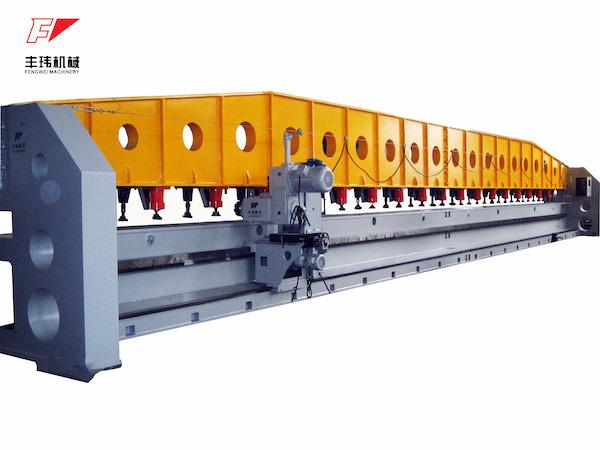

In recent years, the application of tower is more and more extensive. With the rapid increase of demand, tower installation companies have come up with higher requirements on the quality and function of tower production equipment. Fengwei Machinery has years of experience in the field of automatic welding, and has developed and produced automatic welding equipment for tower bar products, including intersecting line cutting machine, internal seam welding equipment, external seam welding equipment, cantilever welding machine, roller frame and displacement machine, etc.

The application of automatic welding and cutting equipment in the manufacturing process of steel tube tower can thoroughly optimize and upgrade the original production process. The traditional production mode adopts the operation of lifting semi-finished products, which requires a special person to be responsible for the lifting and operation of semi-finished products. It has high requirements on the environment and working space, which not only requires a lot of manpower and material input, but also has high labor intensity with low production efficiency. Different from the traditional production mode, the automatic cutting equipment integrates online monitoring, automatic upload and offload raw materials and other automatic functions, can reduce the workload of workers and work intensity, thus greatly improving the production efficiency. The production lines of cutting, pairing and welding can cover each area of the workshop, which can be operated as a whole or independently in each area.

Automation for Power Tower Pole Fabrication

1.Intersecting line cutting machine

It is mainly used for cutting the intersecting line of various lamps and piping systems. Suitable workpiece material: low carbon steel (copper nickel tube, stainless steel tube needs plasma cutting). The machine has beautiful shape, low center of gravity and smooth operation.

Ø System features

Ø The system has comprehensive functions, high stability and strong anti-interference, and is suitable for all kinds of plasma power supply at home and abroad

Ø High cost performance

Ø With digital control function

Ø It can cut multiple cylindrical intersecting line holes in different directions and diameters on the main pipe

Note: Can be customized according to user's specific requirements

2.Circumferential seam welding machine for power pole

Circumferential seam welding machine includes gantry main frame, lateral pressure wheel assembly and welding trolley. The gantry main frame is provided with a floating device, including a lifting driving device and a first pressing plate. One side of the first pressing plate is provided with a sliding block which can slide along the length direction of the first pressing plate, and one side of the sliding block is provided with a welding gun; The bottom of the sliding block is provided with a guide wheel that can rotate along the running direction of the welding trolley, which can ensure that the welding gun can float freely with the height of the pipe fitting in the vertical direction, and keep the welding gun consistent with the weld in the horizontal direction, so that the weld can be tracked automatically without manual intervention. Not only the working efficiency is high, but also the weld forming is beautiful. It can realize single-sided welding and double-sided forming, with high welding strength.

3.Power rod gantry welding machine

Gantry welding machine for power rod is an ideal equipment for automatic submerged arc welding of assembled power rod. Place the workpiece on the welding roller rack and adjust it to the best welding position. The front end of the welding arm is provided with a head fine-adjustment device, which can make the welding arm equipped with submerged arc welding head move horizontally and up and down on the transverse arm of the gantry, align the welding nozzle on the head with the weld, and then the gantry walks in a straight line on the rail to carry out automatic welding. The machine is equipped with automatic flux laying, recovery and processing devices.

In view of the complex process and welding difficulties in the power rod tower industry, FCM has researched and developed a special automatic cutting equipment for the power rod tower/lighthouse industry, as well as assisting clients to plan their whole production process according to the actual production needs of clients.

As pioneering manufacturer of advanced welding automation, Fengwei Machinery also offers variety of machines for Environmental Industry, Petrochemical Industry and Steel structure, with options of welding auxiliary machines and beam welding lines, i.e. welding rotators, welding positioners and welding manipulators.

Call us for free technical proposal, we will offer you a customized layout design with professional services.