Growing Line-Turning Roller Production Line

Combination equipment:Welding Positioner,Welding Manipulator...

-

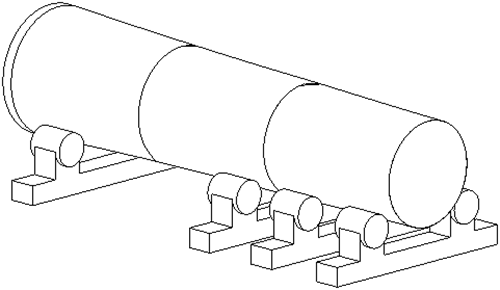

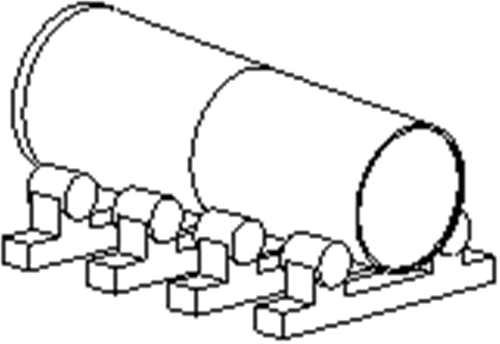

Pipe rotator

Welding turning rolls have very strong advantages for the welding of pipes. Many large metal workpieces are also inseparable from the pipe rotator in welding, polishing, painting, assembly, etc.

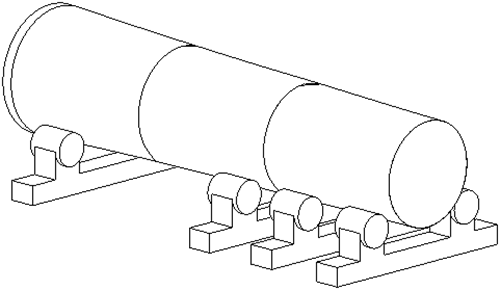

Growing Line-Turning Roller Production Line

Learn more Growing Line-Turning Roller Production Line

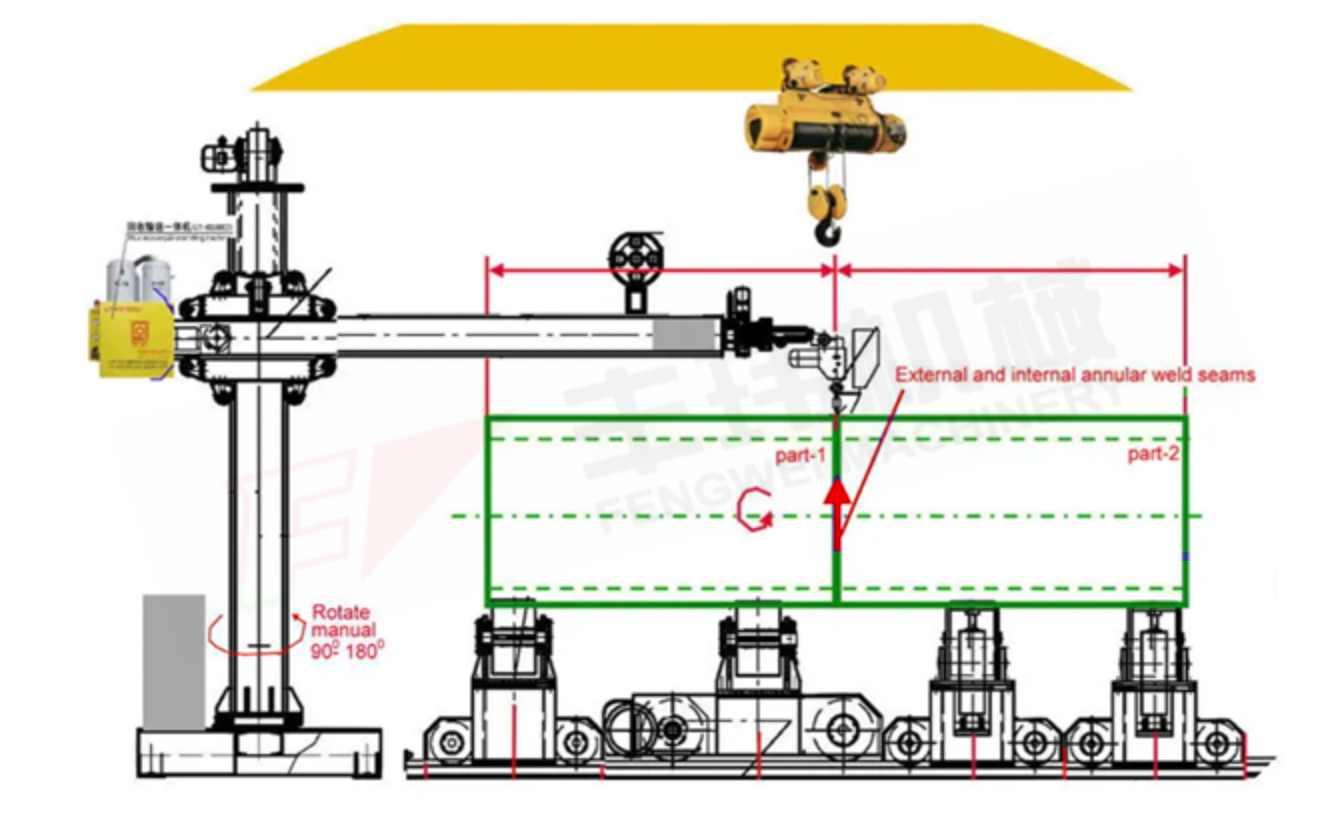

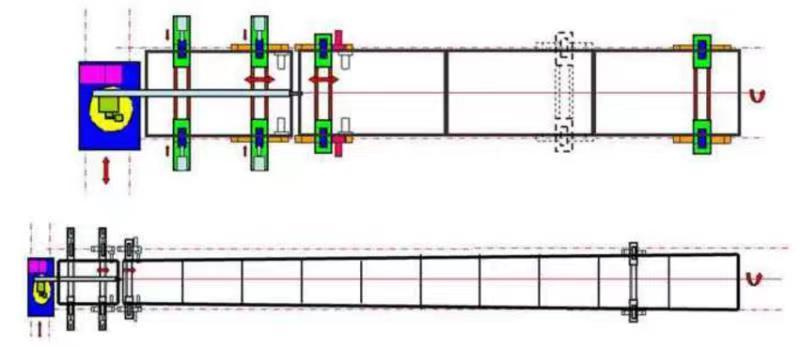

A standard growing line is grouped by a set of fit up welding rotator and a set of conventional welding rotator with trolley. Each wind tower is circularly jointed on the growing line to the targeted length as long as you wish, i.e. 100 meter, so the design of growing line is more ideal based on your targeted wind tower project length.It is free to pair the amount of sets of fit up welding rotators and conventional welding rotators in a line to meet at least 50% fabrication efficiency boost.

In the first section, the wind tower with flange is placed on the set of adjustable welding rotator, and the the other piece of wind tower is placed on on the fit up welding rotator. Moving up and down the position of the 2nd wind tower by fit up welding rotator, it helps 2 sections align togther and assit on weldment by rotating the rotator. The wind tower could be transfered along with rail by the travel welding rotator instead of cranes. In terms of weldment part, column and boom is the choice for circular and longitudinal seam welding. It is optional for fixed or travel model, according to the length of wind tower and space limitation.

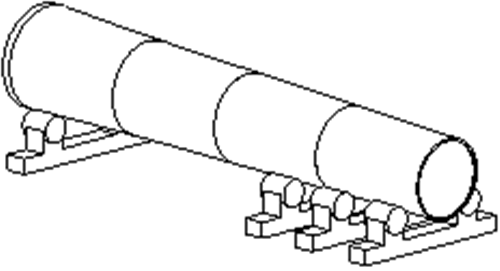

What is the normal procedure of a growing line operation? Please see below:

1st : Load the wind tower section with flange on one set of conventional welding rotator;

2nd: Put the second section on the fit up rotator which helps to adjust the alignment of circular seam between two sections, then do spot welding manually to fix the tanks;

3rd: Select appropriate model of welding manipulator, (right dimension, right configuration etc) to complete internal circular seam welding;

4th: Transfer aligned tanks along with rail by using walkable adjustable rotator;

5th: Put the third section of wind tower on the fit up rotator;

6th: Refer to step 2, and repeat the operation, do spot welding once aligned by fit up rotator.

7th: Welding manipulator assists on welding internal circular seam;

8th: The adjustable rotator move backwards together with the tower body.

9th: Put the fourth section on fit up rotator

10th: Spot welding done by adjusting fit up rotator;

11st: Repeat above steps until the last section with flange is fit up and aligned;

12st: The movable welding manipulator complete all external circular and longitudinal seam welding.

Guidelines For Growing Line-Turning Roller Production Line

A standard growing line is grouped by a set of fit up welding rotator and a set of conventional welding rotator with trolley.