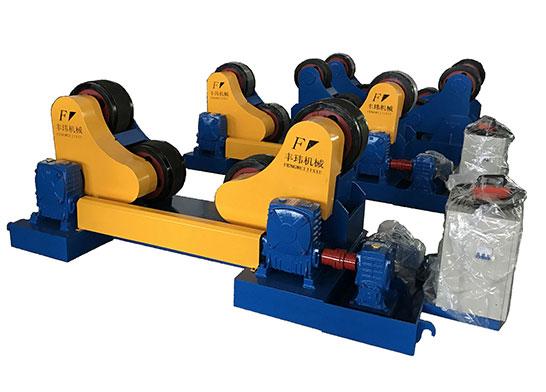

Self Aligning Turning Rolls

Self aligned turning rolls are mainly composed of: base, driving rollers (aka driver), idle rollers (aka idler), driving mechanism, and control system, which is ready to use once delivered, with no installation required. Self aligned turning rolls adopt the friction mechanisms between the roller and the workpiece to lead rotation. The distance between rollers can adapt automatically based on different workpiece diameters, which is different from the mechanism of adjustable turning rolls.

-

Model

Adjustable\Self-aligned\Fit up\Growing line

-

Loading Capacity (kg)

1,000 - 3,000,000 above

-

Roller Material

PU or Metal

The driver and idler frames are made of steel plate structure brackets; main accessories like bearing shafts are made of high-quality steel. They are all quenched and tempered before being processed. Such assembled Self aligned turning rolls can realize the strong rigidity, good performance and high loading capacity.

Each of driver and idler unit has four wheels on the set of Self aligned turning rolls, and four wheels on the driver rotate synchronously. The roller adopts an integral roller structure. PU covered wheels are made of high-quality polyurethane, which has high load-bearing capacity and wearing resistance. Such design avoids aging and degumming, with advantages of high performance and low replacing and maintenance costs.

Swing arm on the Self aligned turning rolls automatically adapts to the requirements of different diameter workpieces. The rotating shaft of the clamp frame on the Self aligned turning rolls assembly has strong rigidity. When the workpiece is placed on the Self aligned turning rolls, the gap between the rotating shaft and the shaft hole can ensure that the clamp frame opens at a suitable angle to adapt the diameter request of workpieces. An oil groove is designed and made on the rotary shaft, which can be filled with grease frequently to ensure good lubrication.

The self aligned turning rolls is widely used for assembly and welding of heavy cylindrical workpieces such as pipelines, pressure vessels, industry boilers, autocalves, and transport tanks, etc. Industry boilers are used to produce hot water or steams, which is made by welding thick steel plates. Autoclaves are commonly used for the sterilization of glass and metal containers, generally in the food industry, with high hermetic standard in production. So assisted by welding manipulator, self aligned turning rolls can be used to weld the inner and outer longitudinal seams or the inner and outer circumferential seams of the tanks to ensure meeting hermetic condition and standards of food industry.

Fengwei Machinery offers a complete custom-built solution.

Construction and selection and manufacture of Self aligned turning rolls are according to CE Standards. Regular examination of all steps of production, using only certified materials and accessories, first-class motor and reducers, guarantees an optimal quality standard of our product. High grade manufacturing precision.

Self aligned turning rolls are pre-assembled to give a compact ready-to-use product. The complete wiring and adjustment at out testing stand avoids trouble at site.

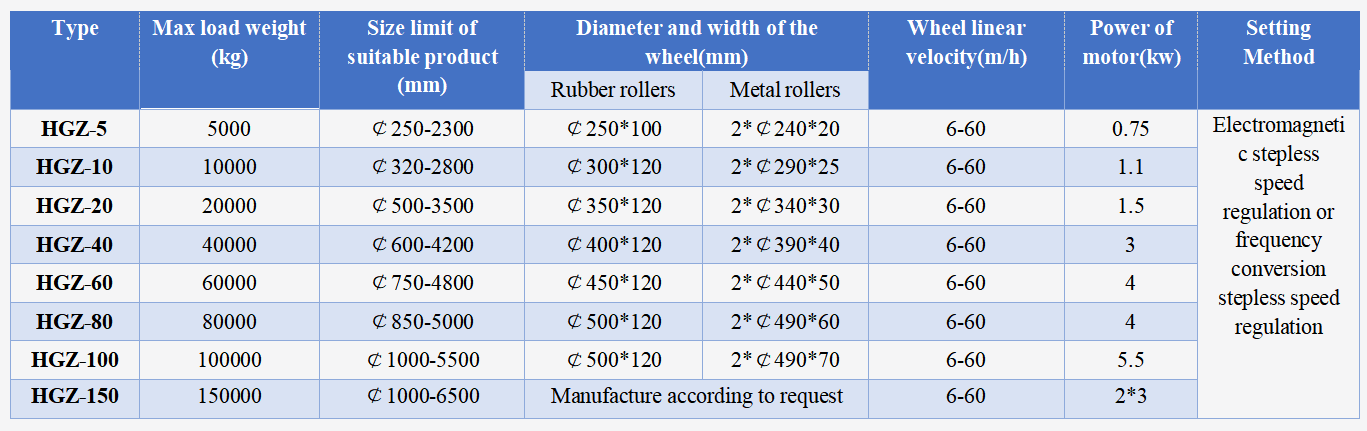

Welding Rotator

The whole welding rotator has strong rigidity and stability, beautiful appearance, reliable performance, simple maintenance and long service life. Learn more about the details and types of welding rotators.