Welding rollers

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators.

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators.

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators. Usually, welding rotators are mainly used in large The welding of such workpieces has certain risks, so we have to pay attention to the welding rollers.

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators. Usually, welding rotators are mainly used in large The welding of such workpieces has certain risks, so we have to pay attention to the welding rollers.

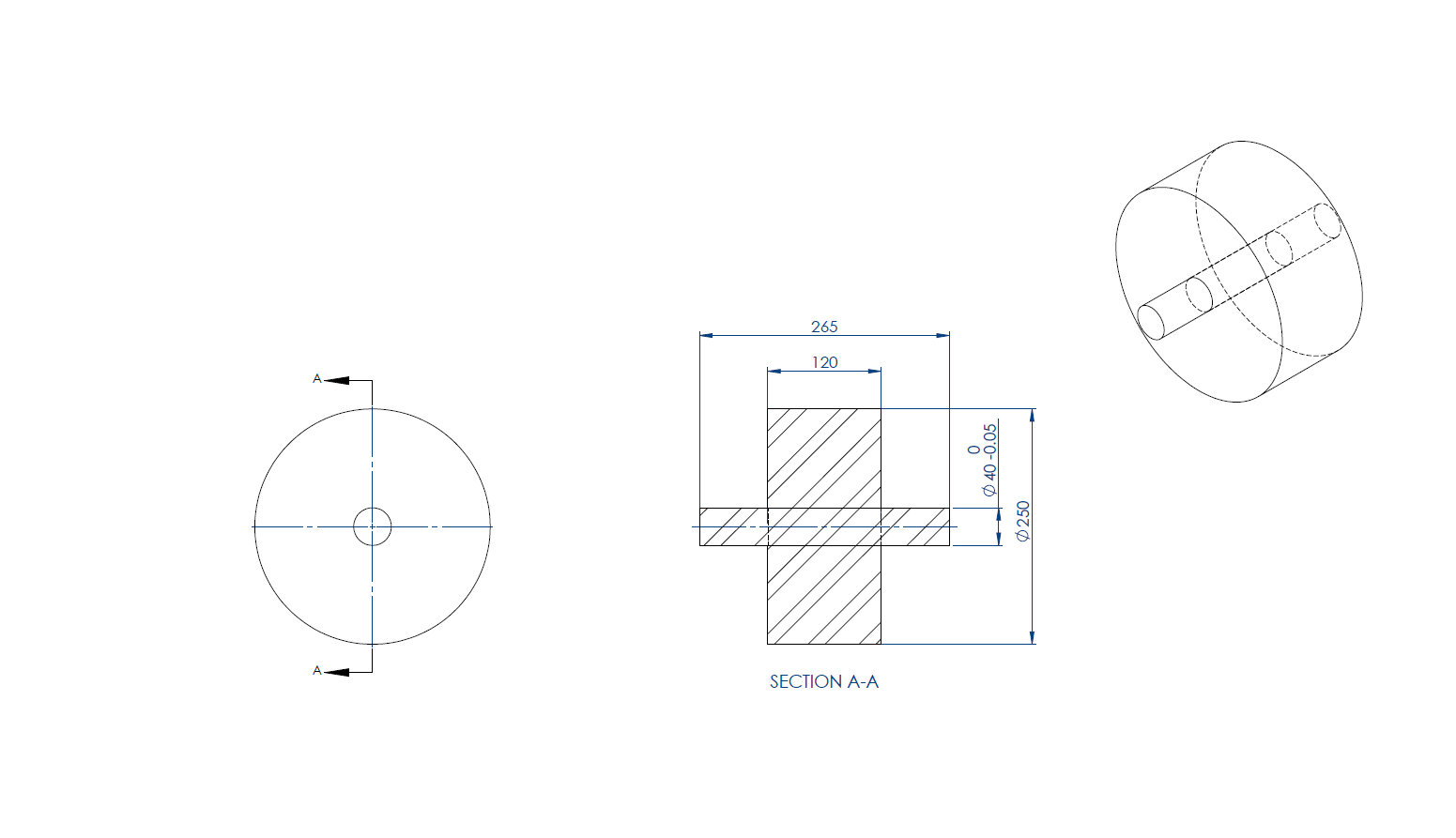

The anti-skid welded rotator roller used in real life mainly includes the core wheel, the core of the flat surface wheel, and the layers on the surface of the outer shell layer, all of which have a specific mesh pattern and a new type of roller device. Before the production of rollers, the most important thing is the design of the mold used to mold the roller. The mold generally has a cylindrical cavity, usually in a hard cavity, with a smooth cavity with a texture. By adopting a structure that moves the roller on the surface, the new type of equipment can accurately remove the sliding phenomenon on the traveling device.

The current practical mechanism welded rotator roller includes a support plate and a vertical moving part, and also includes a clamping assembly, a motor, a vertical moving part, a motor and a clamping part which are mounted on the support plate, the cam translation part and the cam horizontal The moving part, which is mounted on the motor shaft and the shaft, is crossed immediately by the belt passing through the support plate, and is connected to the hub motor output, the vertical and horizontal moving parts of the assembly are cam mechanisms, the vertical moving part and the horizontal moving part are additionally connected to A gripping member is provided, and the gripping end of the gripping member is provided with a gripper.

The new roller device is designed with a mechanism for manually holding the rollers in the new processing steps, which can improve the labor intensity of workers, for welding rotator rollers, the rubber composition is a particularly critical part, only the formulation is used in the production process of the less efficient method so that it can be more suitable for the application, perhaps to ensure that it can be used to ensure that, in full use, professional manufacturers must be intuitive and familiar with the preparation process.

In recent years, with the improvement of the technical level, the welding rotator roller has gradually matured in the development process, which has a great impact on the manufacturing and service life, so everyone can better apply it in the future. The benefits of iron wheel rubber on product quality cannot be ignored.

As a manufacturer and supplier specializing in the upgrading and manufacturing of welding rotators, Fengwei is also paying more attention to welding rollers. For welding rollers, we mainly use polyurethane rollers, and we can also use polyurethane rollers according to different industries. , Customize the required roller material, if you are looking for a suitable welding roller or welding rotator manufacturer, you can contact us at any time, and our engineers will provide you with the most suitable solution.