beam Assembling Welding Straightening Machine

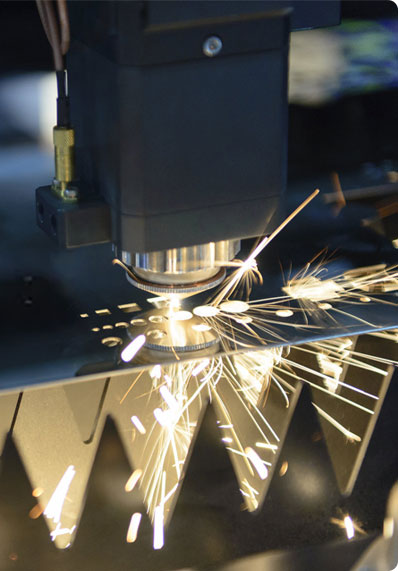

The beam Assembling Welding Straightening Machine is mainly used for the production of H-shaped steel. Different from the traditional split production line, this equipment integrates section steel assembly, welding machine, and straightening, with high production efficiency, small floor space, high plant utilization rate, and labor-saving. beam Assembling Welding Straightening Machine hydraulic correction function, suitable for section steel with wing plate thickness less than 40mm. There are two SAW submerged arc welding machines on the beam Assembling Welding Straightening Machine, and the two welds are welded at the same time. With web and wing plate automatic centering and clamping device to fix the section steel. The host is driven by an AC inverter, which is stable and reliable. The upper-pressure beam is guided by 4 left and right guide rails to ensure stable operation after long-term use.

-

Applicable beam

T、H、I、tapered

-

Optional

automatic spot welding or manual spot welding

The H-beam Assembling Welding Straightening Machine is an efficient equipment for the production of welded H-beams. It can simultaneously complete the precise assembly and assembly of H-beams, submerged arc welding, and correction of flange plate welding deformations on the same machine. The workpieces are welded in the "I" group, which is suitable for the production of H-shaped steel structures with the welding foot height below 12mm. The machine occupies a small area, eliminating the need for lifting and rotating between each process when a single machine is produced, and the efficiency is greatly improved. It is high-tech, economical, and practical production equipment.

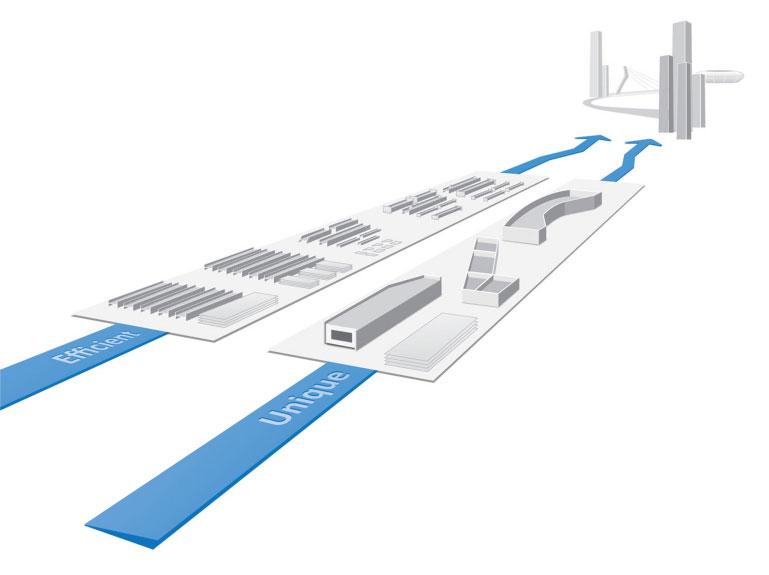

The beam Assembling Welding Straightening Machine integrates the three processes of H-beam assembling, welding, and straightening into one machine. It significantly improves production efficiency, reduces procurement costs, and saves two-thirds of the plant space. Advanced equipment for efficient production of H-beam and T-beam.

With the rapid growth of h beam manufacturers, Fengwei has continuously received orders for H-beam welding types of equipment recently. We’ve been recognized and appreciated by clients in the quality, appearance design, and manufacturing process of our products.

In these 20 years, Fengwei is not only in the pause of deskilling, but also to install over 15 sets of beam integrated welding and straightening machines per month in the domestic and overseas markets with 10% growth continuously. It helps clients reach mass production of over 600-800 tons per month with reduced labor but increased delivery rates.

The development of concrete structures has become quite mature with the rapid development of China and other countries, steel structure technology will become the mainstream of the construction industry in the future with high development. Meanwhile, the demand for beam integrated assembly, welding, and straightening machines is prominent with high requests on cost and workflow efficiency.

Nowadays a large number of steel structure buildings appear in China, and the consumption of steel structures in construction is in an increasing proportion of the yearly output of steel. A large amount of steel is used to meet the needs of architectural modeling and structural design in the area of super high-rise buildings and long-span buildings.

Fengwei Machinery is composed of three business segments: steel structure production line, welding auxiliary machine, and CNC cutting machine. Our intelligent equipment such as light steel production line, heavy steel production line, box beam production line, integrated welding and leveling machine, horizontal production line are well reputation among domestic and abroad clients.

Features of integrated welding and leveling machine

ØIntelligent operation - High degree of automation, one-key start, automatic assembly line operation

ØSaving manpower and material - Reducing the number of normal production line operators by more than 2 times, and 2 workers can guarantee production

ØImproving output efficiency - Reducing the flow of the work-piece, shorten the production and grinding time of the work-piece, and improving the output efficiency

ØEconomic space occupation - Covering a small area, saving installation space, and increasing the output of site area

H beam production line

-

H beam assembly machine suppliers & manufacturers

H beam assembly machine is composed of the main engine, trolley case, input roller table, output roller table, electric control box, operation box, hydraulic station, and other parts.

H beam assembly machine -

Heavy beam Assembling Machine

Heavy beam Assembling Machine consists of the main engine, trolley case, input roller table, output roller table, electric control box, operation box, hydraulic station, and other departments composition.

Heavy beam Assembling Machine