H beam assembly machine

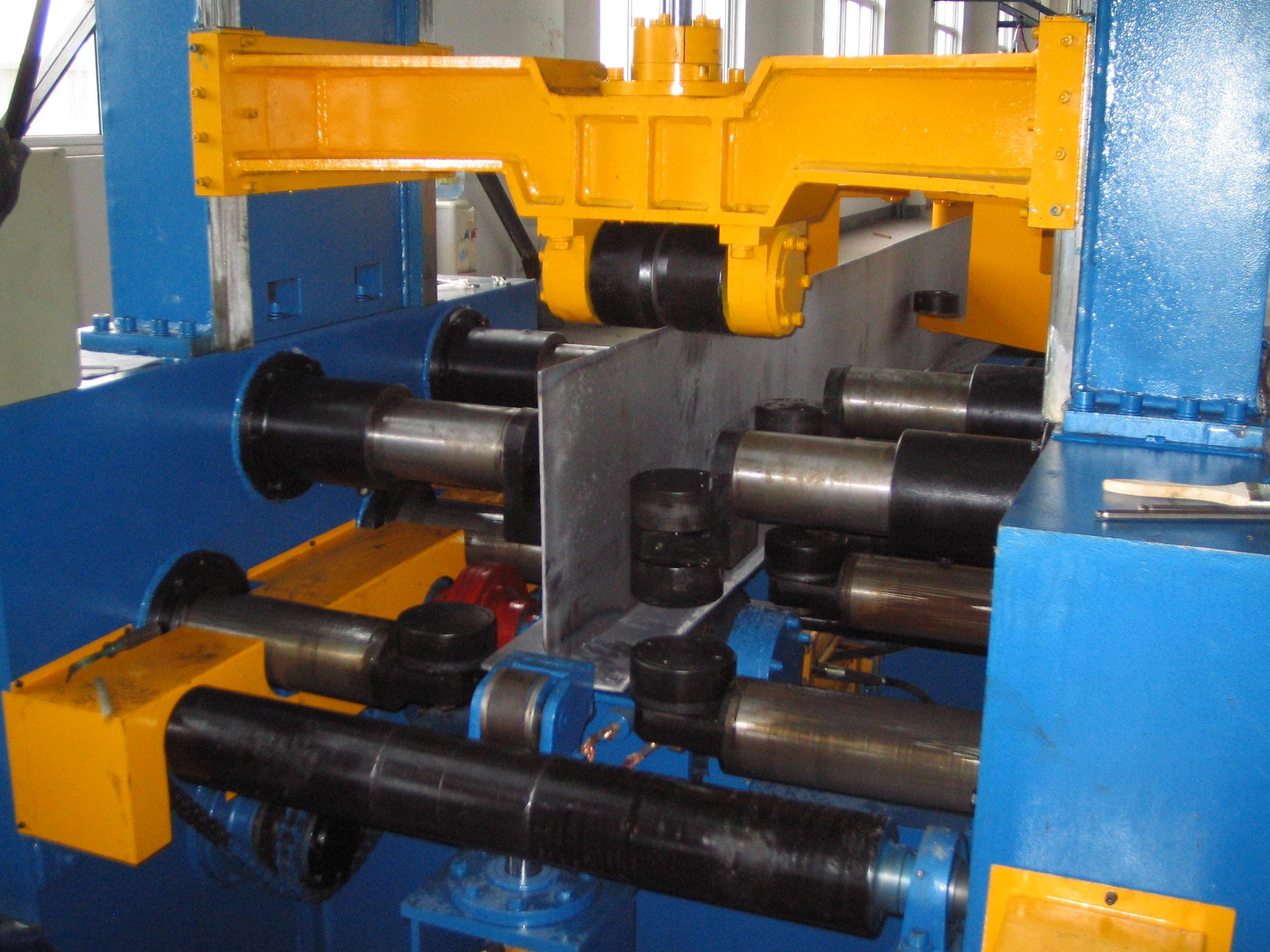

H beam assembly machine is composed of the main engine, trolley case, input roller table, output roller table, electric control box, operation box, hydraulic station, and other parts.

H beam assembly machine is composed of the main engine, trolley case, input roller table, output roller table, electric control box, operation box, hydraulic station, and other parts.

H beam assembly machine is composed of the main engine, trolley case, input roller table, output roller table, electric control box, operation box, hydraulic station, and other parts. In addition, the wing plate, web plate, clamping centering, positioning, automatic spot welding, and other processes of the assembling machine all adopt Japan's Mitsubishi programmable controller and AC frequency converter, so that the automatic control is more than double the efficiency of ordinary products. . The work is stable and reliable, and the welding torch is equipped with a tracking arc guide device, which can ensure the quality of spot welding.

H beam assembly machine is composed of the main engine, trolley case, input roller table, output roller table, electric control box, operation box, hydraulic station, and other parts. In addition, the wing plate, web plate, clamping centering, positioning, automatic spot welding, and other processes of the assembling machine all adopt Japan's Mitsubishi programmable controller and AC frequency converter, so that the automatic control is more than double the efficiency of ordinary products. . The work is stable and reliable, and the welding torch is equipped with a tracking arc guide device, which can ensure the quality of spot welding.

The H beam assembly machine is suitable for spot welding of symmetrical, asymmetrical, eccentric, variable cross-section H beam assembly. The machine adopts the internationally popular manual or electric linkage adjustment on one side, hydraulic pressing on one side, and different speeds for welding and idling. , effectively improve work efficiency. Assembly machine is mainly composed of gantry assembly, tie rod system assembly, hydraulic system assembly, input, and output raceway assembly, electronic control system, etc. Two additional CO2 gas shielded welding machines are used for automatic spot welding.

The main components of the H beam assembly machine are welded structural parts, which are strong and light in weight. Moreover, the important parts have been treated to relieve stress and are not easily deformed. The main transmission part of the erecting machine adopts the transmission mode of motor-cycloidal pinwheel reducer-active roller (the front and rear conveying rollers pass through the transition of the sprocket chain pair), and its linear speed, that is, the erecting speed, adopts AC frequency conversion speed regulation. The main drive roller and the main pressure roller are made of special steel and have undergone special processing, with good wear resistance and high precision. The positioning and centering action of the FENGWEI assembly machine is generally driven by the hydraulic system. First, the tie rod system is used for preliminary positioning and centering, and then the gantry assembly is used for precise centering and clamping.

Assembly machine function

1. Hydraulic motor and gear are used for the automatic centering of the web of the wing plate, which has high centering accuracy and good retention, and all are centrally operated by the electric control button table, which is easy, convenient, and accurate in positioning.

2. The main transmission part adopts a cycloidal pinwheel reducer and Taiwan Tai'an frequency converter, and its assembly speed can be selected within the range of 0.5-6M/min.

3. The synchronous clamping system is used to make the initial automatic centering of the wing plate and the web plate, which fundamentally slows down and avoids the tail swing phenomenon when the section steel is assembled.

4. It can be used as H beam with a variable section.

Advantages of medium-sized H beam assembly machine

1. Compact structure: The main drive system of the unit is built into the main engine, and the site layout is convenient and flexible.

2. The web and wing plate clamping systems are fully optimized: they are all driven by hydraulic motors, featuring high positioning accuracy, large clamping force, a wide clamping range, and convenient use and maintenance.

3. Standard web support module (models above 2000)