welding-manipulator

You might be dealing with welding manipulators in the automated welding line of production if you are dealing in the manufacture of the pipes, large metal workpieces, or pressure vessels.

You might be dealing with welding manipulators in the automated welding line of production if you are dealing in the manufacture of the pipes, large metal workpieces, or pressure vessels.

You might be dealing with welding manipulators in the automated welding line of production if you are dealing in the manufacture of the pipes, large metal workpieces, or pressure vessels.

welding-manipulator

welding-manipulator

Including the MIG welding, submerged arc welding, and TIG welding, the welding manipulator you are selecting can easily undergo various welding processes here; it can effectively help you to get a better welding quality here. For welding the long straight seams, here is where they can be used. These manipulators can be used by blending them well with the welding roller frame to get the long straight seams here. The pipe welding manipulator can be invested in for a complete manipulating system for the welds to get help in terms of recovering quickly through the costs with the increase in the productivity as well as the improved quality here.

It is also very vital to have a complete understanding of every possible welding production while purchasing a standard column along with the boom welding manipulator. These are the factors that would be determining the options that result in the best for you.

welding manipulator batch equipment

welding manipulator batch equipment

The following are the points of consideration in terms of welding out the pipes with the help of the manipulator:

1.Does the welding manipulator need to be moved?

2.Do they have to be able to weld through the long straight seams as well as the circular seams here?

3.Does the base of the manipulator need to be rotated along with the multiple stations for welding?

Compared to the stroke of the welding manipulator consists of the long straight seam of the pipeline here? It is, however, essential to install the trolley for welding with the guide on to the rail device over the base of the welding manipulator here in this case. The welding manipulator can easily move along this pipeline here through the guided rail with the long straight seam located outside of the pipeline can be welded here smoothly with the application of a constant speed in this manner.

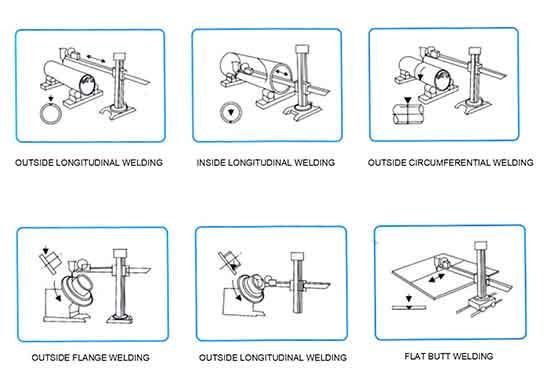

Schematic diagram of welding manipulator

Schematic diagram of welding manipulator

The manipulator here has to be long enough in terms of extending through the pipe for welding inside all along the straight seams here. It can easily control the travel speed of this robotic arm of the welding manipulator for sale as the arm of the manipulator is quite a long one. There should be a variable frequency drive here in terms of making sure. The linear bearings also form a great choice for making sure of the smoother movement along with the repeated positioning of the head of the weld here.

Power of welding

It completely depends on the method of welding you are selecting, defined through its material and thickness.

It can surely offer a single control point for every variable eliminating the chaos of the several welding manipulator controlling boxes irrespective of whether it has an integrated digital control system with the human-machining interface screening. The HMI can be installed easily at one end of the welding arm that lies on the ground, as it all depends on the size of the particulars here.

Supporting auxiliary equipment

You would also require a few of the auxiliary equipment that includes the welding roller too if you are producing relatively larger pipes. The welding of the circular welds can be effectively completed here. The special welding roller frame can also easily drag off the workpiece forward or even backward as it needs the manufacturer to have rich experience in terms of manufacturing, as a matter of fact, with the help of the welding manipulators.

It is not similar to that of purchasing a separate weld manipulator here in terms of buying a welding manipulator. It is considered to be integrated through the automated welding systems here. Whether every component is selected in the proper way or not is what shall be determined here as you need to make some pretty wise choices.

Welding manipulator at work

Welding manipulator at work

Types of pipes used for welding

The welders and even the pipe fitter today are working with the different kinds of pipes here these days. A few of the pipes here need to have the use of specialized techniques and even the equipment. It basically depends on the objective that your project has along with the industry to which it is related in terms of determining the ones that are the best. One of the unique sets of talents that are included here is the ability of skilled welders to help distinguish between the varied kinds of alloys and metals that can be used within the pipes here.

Copper Pipes

A considerable amount of skill would be required in terms of welding the copper pipes. Copper, however, remains one of the well-known metals due to its resistance to corrosion as well as malleability. The widespread popularity in terms of plumbing in many different homes in the past has been enjoyed by the copper pipes here. However, the expensive nature of the copper here has resulted in the reduced use of the copper in several of the plumbing systems here.

Stainless Steel

There are even greater capacities for the robust stainless steel pipes ranging from its production of high-quality pharmaceutical products and even the processed foods to that of the pillars under the girding ocean oil rigs here. It is the best material that suits the underwater projects the best as they are resistant to corrosions. The welders, however, needs the approaches over the stainless steel pipes very correctly, with even the other types of metals that are welded through the weld manipulators.

Cast Iron

It generally occurs through the time being in terms of the cast iron welding. This kind of metal here has gained wide recognition in terms of its usage during these former generations, while at times, the welders has to be welding with it these days. The capable welders have achieved in terms of making some big welds with this sort of pipe through the manual welding that makes use of the MMA process, although they are tough to weld.

Welding manipulator display

Welding manipulator display

Conclusion

The welders can easily work on different types of pipes when they are equipped with the right kind of welding manipulators offered by reputed companies like Fengwei. There are, however, a few of the materials along with the applications that are suited the best in terms of the manual welding processes.