Tank rotator - Wind Tower Production Line

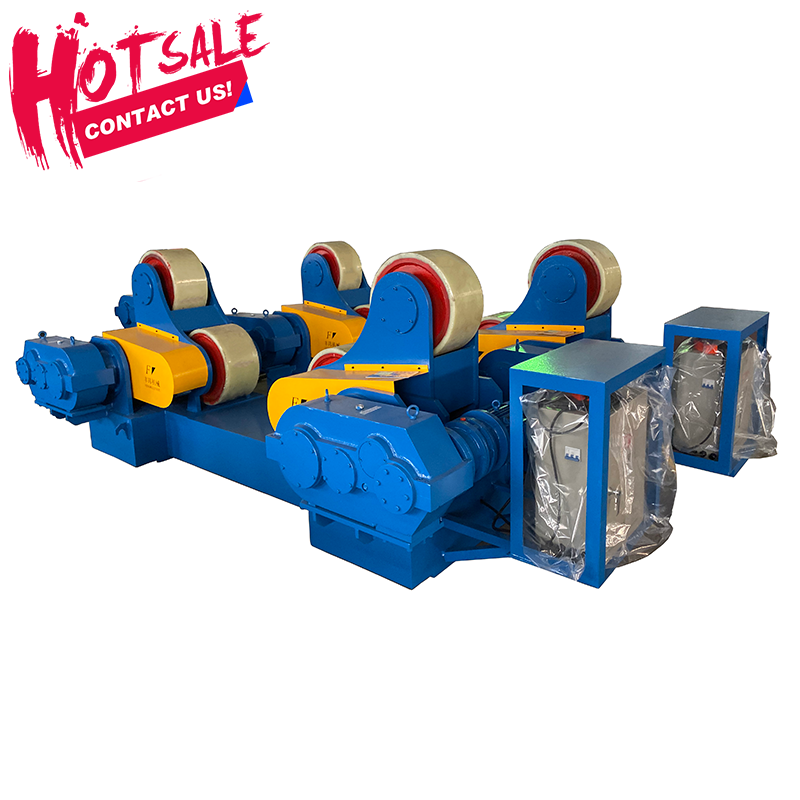

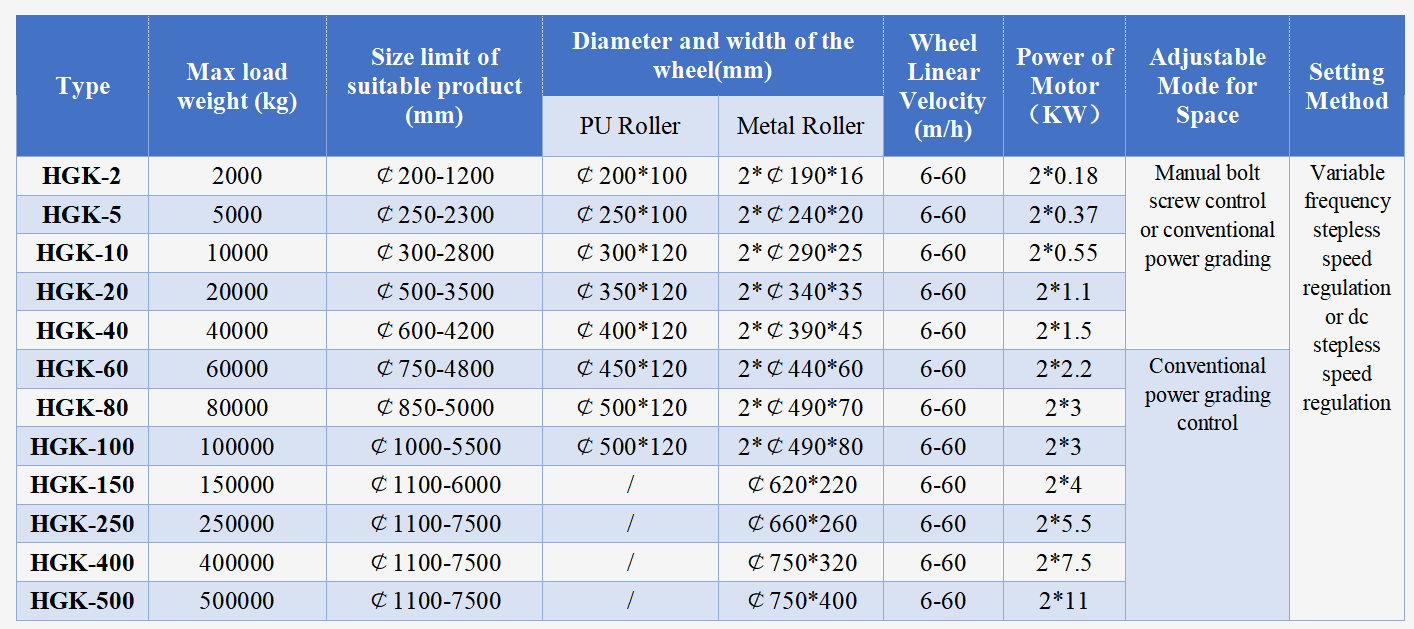

Tank rotator, also known as welding rotator, is mainly used for welding, assembling, and painting large welding workpieces. It can be used in some difficult-to-weld positions, such as circumferential welding: TIG, MIG, SAW, some complex and irregular cylindrical workpieces and its characteristics can be used to complete welding and assembly operations. Different specifications of the tank rotator also have different effects. For specific parameters, please refer to the following content, or you can directly contact Fengwei to obtain the best solution.

-

Model

Adjustable\Self-aligned\Fit up\Growing line

-

Loading Capacity (kg)

1,000 - 3,000,000 above

-

Roller Material

PU or Metal

There are many types of tank rotators, the common ones are screw adjustable rotator (adjustable one), self-aligning rotator, adjustable rotator, conventional welding rotator, small welding roller frame, and so on. The tank rotator sold by Fengwei will have different adaptation schemes according to different industries:

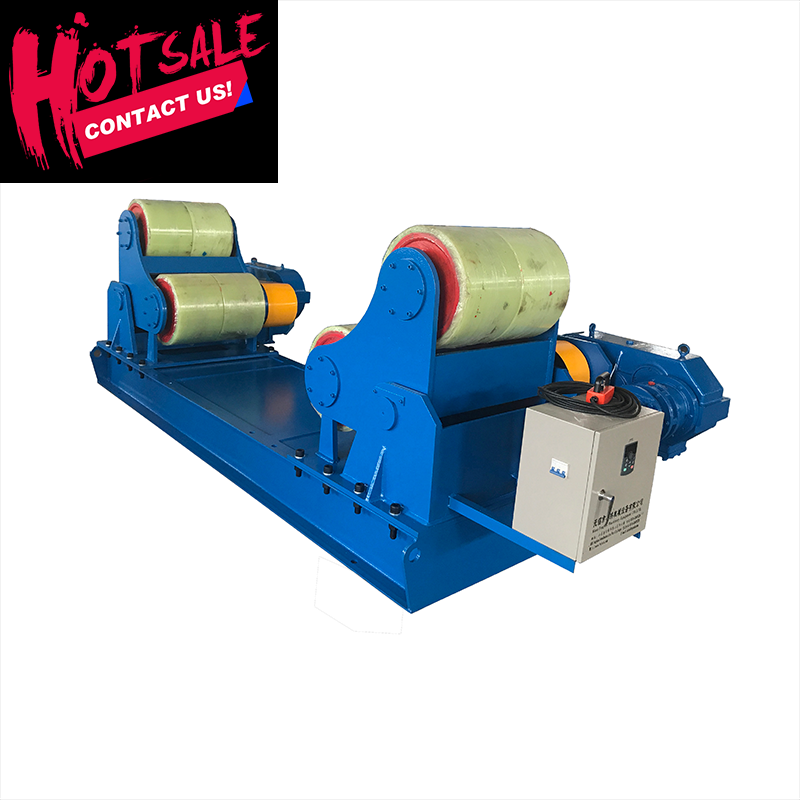

The adjustable welding rotator is mainly composed of a powered rotator, an idler, a drive and deceleration system, and a control system. And this type of rotator has two types: traditional type or adjustable screw type, which can provide choices for various industry needs to a large extent.

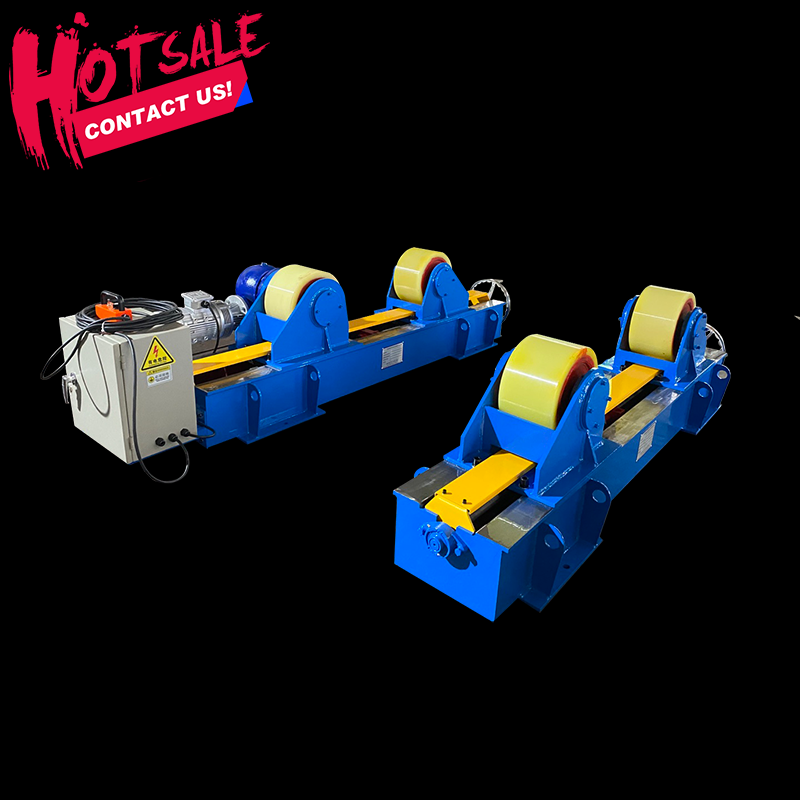

The self-aligning rotator has the function of self-adjustment, and the machine is composed of a set of driving wheels and a set of passive wheels. The driving wheel realizes step-less speed change through the interaction of the motor and the motor gear.

tank rotator applicable industries

Due to the different types of tank rotators, they can be applied to a wide range of industries.

1. Various types of tank welding

2. Wind tower welding and assembly

3. Welding and assembly of ships

4. Pressure vessels and boilers

5. Storage tanks for oil and gas

Matching components of tank rotator

Each component of the tank rotator is designed with the most top and most popular, including design rollers, motors, control systems, etc.

1. Using polyurethane roller (PU roller)

2. Adopt the most popular step-less speed regulation

3. With the controller, the operation can be completed by remote control, and the safety of the work process can be ensured.

Fengwei Machinery provides complete tank rotator customized solutions

The tank rotator is constructed, selected, and manufactured to CE standards. Regular inspection of all steps of production, the use of only certified materials and accessories, first-class motors and reducers, ensures the best quality standards of our products and high manufacturing precision.

Wind Tower Production Line

-

Self-adjusting Welding rotator|Safety Operation Guide

Fengwei has 20 years of experience in the design and development of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world.

self-adjusting welding rotator -

welding rotator|US hot sale

Fengwei is a professional in the manufacture and research and development of welding rotators. Various types of welding rotators have been recognized in the welding application fields of various large-scale equipment in the United States.

welding rotators -

Welding Roller | Welding rotator manufacturer

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators.

Welding rollers -

The Best Quality Self Adjusting Welding Rotator From China

Self-adjusting welding rotator is a kind of equipment used with a welding manipulator, which is used to support or drive rotation when welding straight seams and circumferential seams of pressure vessels and large-diameter pipes.

Self-adjusting welding rotator -

Improve Weld Quality|Welding Rotator

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding.

welding rotator -

Adjustable Welding Rotator - Explosion-Proof & Anti-Channeling

The adjustable welding rotator consists of a driving frame and a driven frame as a set and generally does not need to make an installation foundation.

welding rotator