Pipe Rotator For Welding

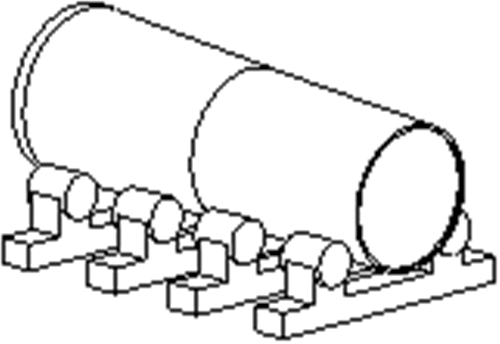

FENGWEI pipe rotator is a tool that makes welding pipes and other circular items easier. By integrating two rolling metal pieces, they may work with small or huge sizes while saving time. This frees up both hands to concentrate on welding. A base, a power driving device, a driving roller, and a driven roller make up the pipe rotator.

-

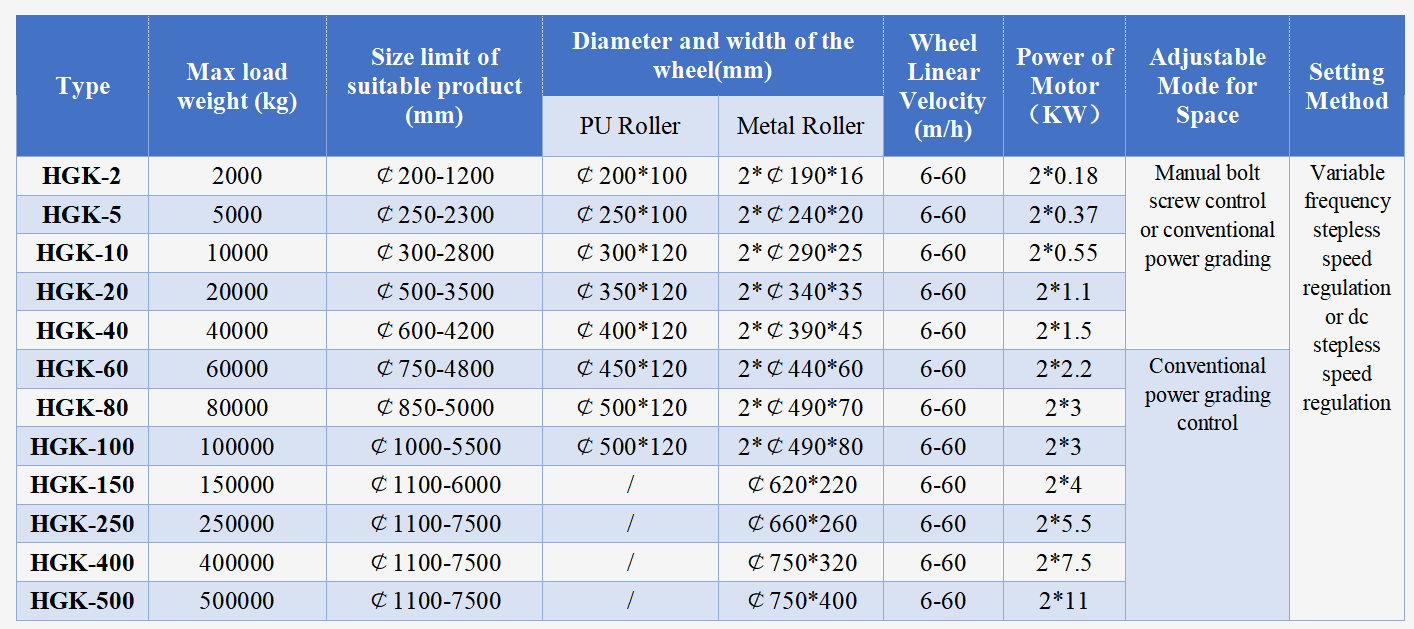

Model

Adjustable\Self-aligned\Fit up\Growing line

-

Loading Capacity (kg)

1,000 - 3,000,000 above

-

Roller Material

PU or Metal

The operating device controls the active rotator of the pipe rotator, and grafting happens between the active rotator and the cylindrical component. This friction force can primarily drive the workpiece's rotation, resulting in effective displacement. This will improve welding quality to the fullest extent possible and increase job efficiency significantly.

Working process of pipe rotator

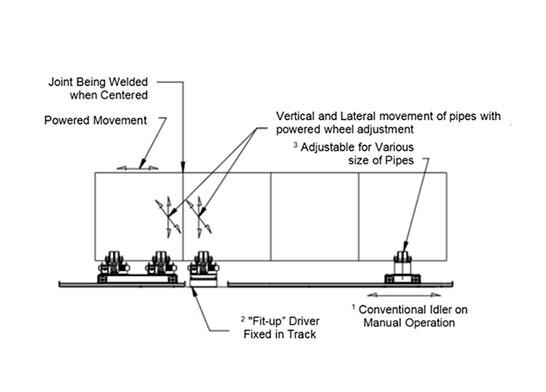

It pays to be able to fabricate identical objects quickly when doing so regularly. Being able to rotate a welded piece automatically is thus a fantastic idea. Engineers who develop machinery have already considered this. They have designed rotators that rotate the stock for a variety of uses. Two massive sections of metal tubing, for example, will make up a pipeline, and must frequently be welded together. The two massive pipes are put on the welding positioner's wheels to achieve this safely and swiftly. The wheels allow him to rotate the task while welding. It is possible that the pipes can be welded completely in one pass using this configuration.

The complexity of this tool

A rotator is scaled to execute a certain function because the objective is to automate a welding job. The rotator will most likely be simple if the job requires making little pieces repeatedly. If work requires sophisticated welds, the complexity of this tool will increase as well. Some rotators have become so sophisticated that computers must manage them. Some machines are numerically controlled by a computer tool. Rotators for welding have already reached this level of sophistication.

What causes the material to move when the pipe rotator is used?

When utilising a pipe rotator, ensure that the rotator and the weldment are both spherical, that the lengths are equal, and that the axes are aligned. The selection of the product on the roller frame may cause movement if one of the rollers in the roller frame is broken. Of course, if the material shape or size is uneven, it will move as well. This is due to the rotator's axis not being parallel to the material axis.

Effects of using pipe rotators

A pipe rotator is utilized to accomplish related jobs throughout the welding process. The rotator frame is designed and manufactured using modern technology. While the application purpose is fulfilled using an automatic tracking system, resulting in more precise positioning. The process design can be handled according to the operating requirements when the roller rack is used for processing and production, allowing the roller rack to suit the industry's needs.

Roller materials of the pipe rotators

A welding roller is a tool that is frequently used in welding operations. The scroll wheel is the most important part of it. Polyurethane rollers and steel rubber combination wheels are two of the most prevalent types of rollers. Users can customize their purchases to meet their requirements. However, you must be aware of the distinctions. The polyurethane roller on the welding roller is made of polyurethane, an organic polymer substance. Oil resistance, toughness, abrasion resistance, and age resistance are all good qualities. It also has substantially higher tensile strength, rips strength, abrasion strength, and other qualities than conventional rubber.

Large pressure-bearing capacity and long rubber wheel life are two properties of steel-plastic composite rollers. The surface of the worm tooth has also been treated using quenching and grinding. As a result, it has excellent efficiency and a long lifespan.

The best way to keep your pipe rotator in working order

Many people claim to have used pipe rotators for many years, yet they may not know how to maintain them in good working order. So here are some pointers on how to keep it in good shape.

· The gearbox must be filled with mechanical oil, and the ambient temperature must be below 0°C when the pipe rotator is placed and operated. After the first month of use, the oil should be changed completely every six months.

· Before using the pipe rotator, make sure it is clean. To prevent aging, keep the rubber roller away from oil and heat. An alternative person should be assigned to operate and maintain the pipe rotator if at all possible.

· The welding ground should not be put on the roller table to avoid damage to the bearing.

· All transmission parts should be lubricated regularly to guarantee that the equipment works properly.

Feature of pipe rotator structure

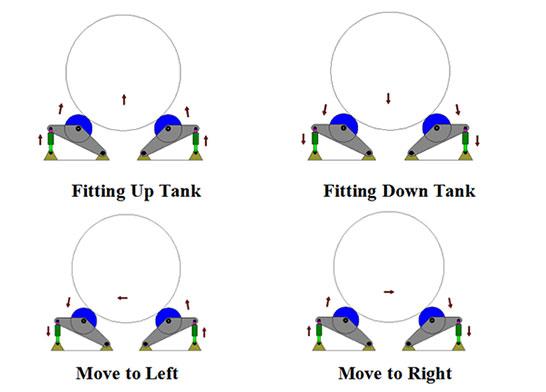

A pipe rotator is an instrument that utilizes compression between the weldment and the active roller to rotate a cylindrical or curved weldment. It can be put together based on the weldment's weight and length and it is straightforward to use and versatile.

· Automatically modify the center distance of the roller within the given range, suited for welding of various diameters, cylinder welding components put smoothly.

· Stepless speed regulation, welding speed range, and speed stability are all power supplies drive features.

· commonly utilized, applicability

· rubber, smooth transmission, friction, extended life, integrated roller, steel wheel outsourced

· The workpiece wheel pressure is low, which prevents cold work hardening on the work surface.

Best way to clean the welding rollers?

It is easy for dirt to attach to the welding roller during the application procedure. Its rollers, in particular, must be cleaned with a special welding roller rack cleaning chemical. The welding rollers and other elements must also be removed for cleaning.

Wrapping it up

A pipe rotator is a piece of auxiliary welding gear. It can weld cylindrical workpieces' inner and outer longitudinal seams and their inner and outer circumferential seams. It rotates the cylindrical welding workpiece by using friction between the welding workpiece and the roller. pipe rotators are frequently used in conjunction with welding manipulators. As a result, if you want to buy a pipe rotator, you can approach Fengwei, the leading producer, and they will assist you in selecting the best equipment for your needs.

Welding Rotator

The whole welding rotator has strong rigidity and stability, beautiful appearance, reliable performance, simple maintenance and long service life. Learn more about the details and types of welding rotators.

-

Self-adjusting Welding rotator|Safety Operation Guide

Fengwei has 20 years of experience in the design and development of welding rotators, among which the self-adjusting welding rotator has been recognized by partners from all over the world.

self-adjusting welding rotator -

welding rotator|US hot sale

Fengwei is a professional in the manufacture and research and development of welding rotators. Various types of welding rotators have been recognized in the welding application fields of various large-scale equipment in the United States.

welding rotators -

Welding Roller | Welding rotator manufacturer

Welding rollers play a crucial role in the structure of welding rotators. Different materials of rollers have unnecessary welding auxiliary effects. The most important one is the anti-slip effect of welding rotators.

Welding rollers -

The Best Quality Self Adjusting Welding Rotator From China

Self-adjusting welding rotator is a kind of equipment used with a welding manipulator, which is used to support or drive rotation when welding straight seams and circumferential seams of pressure vessels and large-diameter pipes.

Self-adjusting welding rotator -

Improve Weld Quality|Welding Rotator

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding.

welding rotator -

Adjustable Welding Rotator - Explosion-Proof & Anti-Channeling

The adjustable welding rotator consists of a driving frame and a driven frame as a set and generally does not need to make an installation foundation.

welding rotator