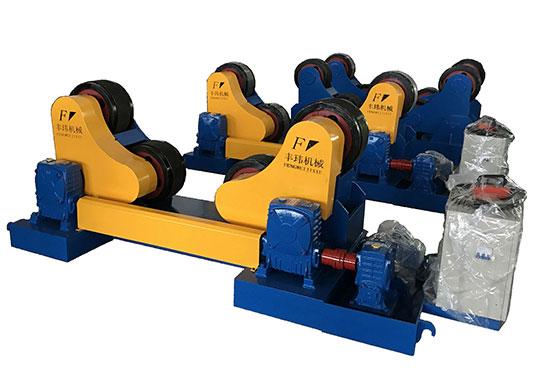

Welding Rotator

The self-adjusting welding rotator can be used for the assembly and welding of heavy cylindrical workpieces such as pipes, containers, boilers, oil tanks, etc.

- High welding precision

- High durability

- Strong applicability

The self-adjusting welding rotator can be used for the assembly and welding of heavy cylindrical workpieces such as pipes, containers, boilers, oil tanks, etc.

The self-adjusting welding rotator can be used for the assembly and welding of heavy cylindrical workpieces such as pipes, containers, boilers, oil tanks, etc., involving the fields of petroleum, civil engineering, automobile, and ship construction. The self-adjusting welding rotator can be directly used with a welding manipulator, welding positioner, submerged arc welding machine, and other equipment to realize inner and outer longitudinal seam or inner and outer circumferential seam welding of some difficult-to-weld workpieces or cylinders.

The self-adjusting welding rotator has particularly strong applicability. Its roller device can be adjusted according to the size of the workpiece. After the user adjusts the height of the main and driven roller groups appropriately, the welding and assembly of irregular workpieces can be realized. The welding rotator can also weld some non-cylindrical or non-circular welding workpieces. It is only necessary for the user to install it in the special ring clamp made by FENGWEI during use, and the entire welding process can be easily completed or assembled.

Combination equipment for welding rotators

1. Welding positioner

The welding positioner can be used in combination with the welding rotator, which is mainly used to realize the normal operation of welding automation and some difficult-to-weld workpieces. When choosing a welding positioner, you need to choose a type that is safe, easy to operate, simple, and compact in structure, and you need to choose the appropriate equipment according to your welding workpiece. When welding large-scale equipment in the factory, the selected welding positioner generally uses a high-height machine. To ensure the safety of personnel and the normal use of the machine, the operator must be elevated to operate to prevent the operation from occurring. Mistakes. Considering the combination of manual welding, the welding positioner we choose must perform flat welding on any weld to avoid overhead welding and vertical welding, and we must effectively ensure the quality of the entire welding.

2. Welding manipulator

There are many types of welding manipulators, and between different structural parts, the gaps in their shapes are relatively large, so when operators use welding manipulators, they will also have certain operations according to different machines. difference. Therefore, according to the different structural parts of the workpiece and welding requirements, it is also very important to choose a suitable welding manipulator. If you cannot choose a suitable machine, you can find a reliable welding manipulator manufacturer, and they will give you the most suitable program.

The self-adjusting welding rotator has a specification of 1-1000t, and the welding rotator with a larger specification can also be customized by contacting the welding rotator manufacturer, but each specification of the welding rotator has its advantages and disadvantages. When the diameter of the welding workpiece exceeds 3500mm, it is necessary to choose a welding rotator with a large tonnage.

The welding workpiece can be welded stably on the welding rotator, which is inseparable from the material of the welding roller. The commonly used materials are mainly steel-plastic combined rollers, polyurethane rollers, metal rollers, etc. The materials of different rollers are selected through workpieces of different specifications.

The self-adjusting welding rotator can be used for the assembly and welding of heavy cylindrical workpieces such as pipes, containers, boilers, oil tanks, etc.

Through the rotation and flipping of the welding turntable, the workpiece welding seam is in the best welding position for welding or rotating welding with other equipment.

Welding PositionerThe self-adjusting welding rotator is mainly composed of two sets of driving wheels and driven wheels. The rollers of the welding rotator adopt an internal iron core and external rubber structure, which have the characteristics of strong applicability, du

Self-adjusting welding rotatorFor CNC cutting manufacturers, based on the research and development, manufacturing, and sales of welding rotator machinery and equipment for many years, it has been found that the setting of the initial heating speed for laser cutting has become a crucia

Welding RotatorThe welding rotator is mainly used in the equipment for the rotation of electric welding parts. It drives the welding parts to rotate by rotation.

Welding rotatorWhat is a welding rotator? It is a frictional ability achieved by the accessories, which can effectively ensure that the rollers are on the same axis for a long time.

Welding rotatorThe welding process of the welding rotator must be checked one by one for the relevant steps in the welding process.

Welding rotatorThe welding rotator is mainly used for welding, polishing, lining, and assembling cylindrical cylinders. It can also be matched with another tooling, such as welding manipulators, welding positioners, etc. Assembly and welding of radial rotors.

Welding RotatorThe pipe welding rotator consists of seven parts: machine base, driving device, column, cross arm, pressing device, column rotating mechanism, and remote control box. The cross arm can be lifted up and down electrically along the column guide rail and can

pipe welding rotatorThe anti-channeling and explosion-proof welding rotator generally adopt two driving methods: DC speed regulation and AC frequency conversion speed regulation to achieve the smooth rotation of the weldment with step-less speed regulation.

welding rotatorWelding rollers have a variety of styles, mainly to meet the welding needs of various specifications and irregular welding workpieces. The common ones are self-adjusting, adjustable, flat car, tiltable, and anti-axial movement.

Welding rollersThe turning roller can drive the circular weldment to rotate through the friction between the weldment and the driving roller to complete the welding of the annular weld. The welding speed can be adjusted by the speed of the active roller on the Turning r

Turning RollerA welding rotator is a common electric welding auxiliary equipment, which is widely used in the welding process of various large cylinder equipment.

welding rotatorThe welding Rotator produced by Fengwei Machinery is widely used in various industries, such as reactors, boilers, and ship manufacturing. A qualified welded Rotator manufacturer must ensure its equipment and must have high standard standards.

Welding Rotator