welding-positioner

A welding positioner is a piece of universal and efficient welding equipment for circular welding. Can be equipped with argon arc welding machine (wire filling or no wire filling)

A welding positioner is a piece of universal and efficient welding equipment for circular welding. Can be equipped with argon arc welding machine (wire filling or no wire filling)

A welding positioner is a piece of universal and efficient welding equipment for circular welding. Can be equipped with argon arc welding machine (wire filling or no wire filling), melting gas welding machine (C02/MAG/MIG welding machine), plasma welding machine, and other welding machine power supply, and can be combined with other sets into automatic welding system. The product is mainly composed of a rotating head, displacement mechanism, and controller.

Elevating welding positioner

Elevating welding positioner

Due to the difference in development level between manufacturing industries, many enterprises have not equipped welding positioners in their welding stations. At the same time, the relevant research is relatively weak. So what details need to be paid attention to in the use of welding positioner? Fengwei Machinery through years of experience, summed up the next 12 important points for the use of welding positioner notes, let's see what are there?

Main parts of welding positioner

Main parts of welding positioner

1. Operators need to read and comply with welder safety operation rules before operation.

2. When installing and disassembling the workpiece, it is necessary to check whether the round pressure plate has been removed and whether the pressure plate is back in place to prevent the workpiece from damaging the fixture.

3. Pay attention to the work center when installing the workpiece, and do not deviate from the center of gravity.

4. Overweight and overload shall not be allowed.

5. When lifting the workpiece, it must be stable and level, without a large swing, to prevent the workpiece from colliding with the fixture, so as not to damage the fixture.

6. When hoisting the workpiece, the sling can be removed from the workpiece only after it is properly installed.

7. When disassembling the workpiece, the workpiece must be stabilized by the sling before it can be loosened.

8. When the workpiece falls on the fixture, it should be put lightly, and there shall not be too much impact on the fixture and the positioner.

9. The workpiece installation must be positioned according to the requirements, the nuts and bolts of the fixture should be tightened, and the pressure plate should be pressed. After the installation is completed, a test transfer inspection is required to confirm the installation stability before formal operation.

10. When the workpiece needs climbing welding, the climbing pedal shall be used, and the climbing pedal shall be placed safely before climbing operation.

11. Before rotation, check whether there are other objects within the working rotation range to avoid the collision.

12. After the workpiece is transferred to the working position, the power switch must be turned off to prevent misoperation.

There is also a situation that affects the use of welding positioner is also the key, that is the maintenance and processing of welding positioner chuck.

Displacement of welding machine is in use, in order to ensure the smooth implementation of the welding process, the welding, can play a good supporting role, can achieve good effect in the later use, displacement machine is one of the important parts is the use of welding chuck, chuck used to ensure the normal use of the welding machine, Therefore, in the later maintenance, we should not only pay attention to the maintenance of the positioner but also pay attention to the maintenance of the chuck. Next, we will introduce it in detail.

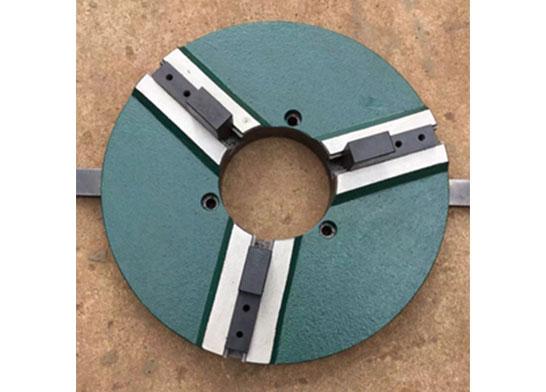

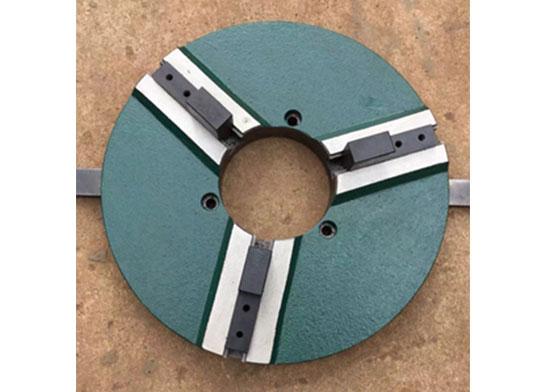

Welding positioner chuck

Welding positioner chuck

1. After the chuck is used, clean the welding chuck body and the surface of the guide rail of the welding positioner with tools such as an air gun. As a result, good accuracy can be ensured even after a long period of use, so regular lubrication of chucks is important.

2. At least once a day molybdenum disulfide grease (black color), the grease into the grease nozzle of the welding chuck, until the grease from the gripper surface or welding chuck inner hole (inner hole protection cover and nut) overflow.

3. Prevent internal rust chuck, clamping force decline, unable to clamp the workpiece, so the use of the antirust effect of cutting oil, the use of cutting oil can prevent internal rust chuck.

4. After the operation, use air guns to clean the welding chuck body and slide surface.

5 chuck at least every 6 months to remove cleaning, keep chuck jaw bending surface clean, give lubrication, prolong the life of the chuck.

6. Check whether all parts are cracked and worn, and clean the cast iron completely at least once every two months. If there is major damage, replace the new one immediately.

7. Each workpiece needs to use a different clamping method, using it to clamp an irregular workpiece will damage the welding chuck.

8. In the case of abnormal chuck pressure, if high pressure clamping chuck, chuck life will decline, so found that the clearance of chuck is too large, the need to immediately replace the new chuck.