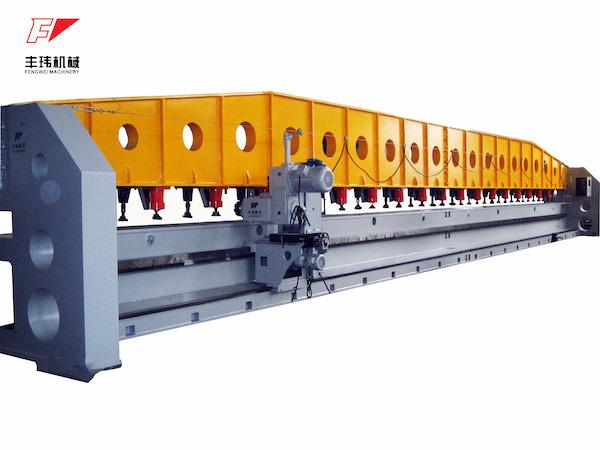

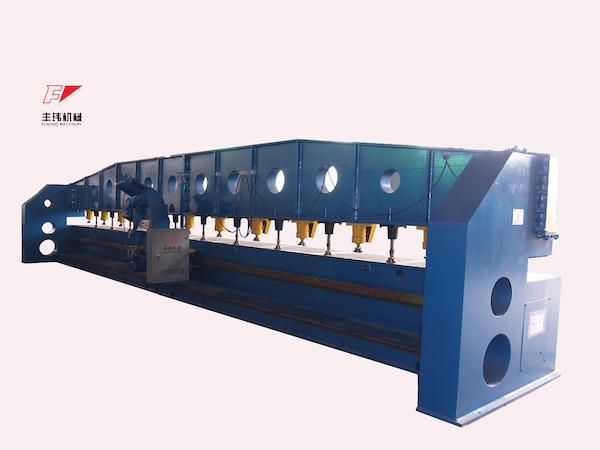

Edge Milling Machine

The edge milling machine produced by Fengwei has been widely used in the production of spiral welded pipes with its significant advantages.

The edge milling machine produced by Fengwei has been widely used in the production of spiral welded pipes with its significant advantages.

The edge milling machine produced by Fengwei has been widely used in the production of spiral welded pipes with its significant advantages. Not only that, but our edge milling machine is also widely used in boiler, pressure vessel manufacturing industry, shipbuilding, electric power, petroleum, chemical machinery, engineering machinery manufacturing. Machining, bevel edge, straight edge, and U-shaped groove can be milled and formed at one time. Compared with edge planer, it has the advantages of low price, low energy consumption, high work efficiency, high finish, convenient operation, and maintenance, etc.

The edge milling machine produced by Fengwei has been widely used in the production of spiral welded pipes with its significant advantages. Not only that, but our edge milling machine is also widely used in boiler, pressure vessel manufacturing industry, shipbuilding, electric power, petroleum, chemical machinery, engineering machinery manufacturing. Machining, bevel edge, straight edge, and U-shaped groove can be milled and formed at one time. Compared with edge planer, it has the advantages of low price, low energy consumption, high work efficiency, high finish, convenient operation, and maintenance, etc.

Compared with the disc shear, the edge milling machine improves the processing quality of the plate edge, makes the forming and welding process more stable, reduces the consumption of the plate, and improves production safety. However, the edge milling process also has inherent shortcomings. If the control is not good, it will lead to a series of forming and welding defects, such as pores, slag inclusions, incomplete penetration, burning collapse, welding deviation, and irregular welding beads.

Correct use of edge milling machine milling method

1. Reasonable selection of milling process and parameters

The milling process is reasonably selected according to the actual production situation. Under the condition of guaranteeing production, try to adopt a single edge milling process and choose a type I groove, to reduce edge milling defects and make it easy to process. Select the appropriate working width, generally, choose the milling amount of 8-10mm. That is, the working width of milling = the narrowest actual original plate width - 8mm.

2. Flexible adjustment of milling machine

In specific cases, the edge milling machine can be flexibly adjusted to suit different situations. For example, when the deviation of the working width of the steel plate is 1-3mm, the forming quality is generally not affected; when the edge of the steel plate deviates from the delivery line by 1-3mm, it can be controlled. Therefore, when the steel plate is about to be de-milled out of control, it can be controlled by fine-tuning the headstock. Another situation is: if the width of some steel coils is not too large, the working width of the edge milling machine can be fine-tuned to reduce the amount of blade milling and prolong its service life.

3. Standard use and blade replacement

The edge milling machine must be regularly lubricated and maintained to ensure the integrity and stability of the equipment. Coated blades with better wear resistance and better heat dissipation must be selected and replaced in time and regularly. It should be noted that the milling cutter disc pursues the overall effect. If only some of the blades are replaced, it will cause "metal wire" defects and increase the working strength of other blades. Therefore, all the blades must be replaced when changing tools.

Compared with traditional edge milling machines:

The guide rail installation form is detachable, and through heat treatment, the bed structure is reasonable, the milling head runs more smoothly and reliably, the feeding system and the return system are completely independent, the return speed is fast, the efficiency is high, and the angle of the milling cutter head is easy to adjust. , The custom cutter head is interchangeable with the standard cutter head, which is a replacement product of the traditional edge milling machine.

The following steps should be followed when the edge milling machine is blanking and unloading:

1. The 1C-shaped single-column press will deflect the angular wave mode during welding, while the double-column edge milling machine has a stable structure, and the action is accurate according to the size of the workpiece and the load (centering or eccentricity) of the weld, and there is very little deflection. Suitable for eccentric load machining. Likewise, setting the preload on the edger is simple.

2. Now the productivity requirements are low, and edge milling machines are generally used for blanking small and medium-sized parts, and the production cycle generally does not exceed 20-40 pieces per minute. The four-column edge milling machine has a deflection of the action point of its force and its geometric center. Whether it is a two-column or four-column press, its body structure must be able to withstand the shock and vibration caused by blanking, and the molding method determines the structure of the edge milling. C-shaped frame.

3. Cushioning function (may cause damage to the press when pressing two pieces)

The only way to find out the benefits of using an edge milling machine is to know whether the adjustment of the slider stroke range and the welding port control meets the processing requirements. Preload is used to offset the impact of workpiece weight or emergency stop.

The device failed to eject the machined part. When designing the press, when two pieces of material are put on the mold when feeding, or when the mold is ejected, the setting of the edge milling machine is very difficult. If the stroke range is set, the milling machine should be selected.

4. When there is such a requirement, using the edge milling machine can quickly change the settings;

For products with diverse types, complex program settings are often required, which are easy to set up with an edge milling machine; the frequency of JIT component replacement is high;

When the program setting is more complicated to process small pieces (1-2 inches), the beat is 60spm; when processing large pieces (3-15 inches), the beat is 30-40spm; the production beat of the edge milling machine is slower;

For the blanking process that meets the following requirements, it is ideal to use an edge milling machine:

At this time, it is possible to cause double pressing to improve its firmness. In this case, the mechanical press may be damaged to reduce the impact of blanking. Designers often design blanking presses to be twice as heavy as the standard configuration. The edge milling machine has an overload protection function, which limits the highest welding port, so it will not be damaged.