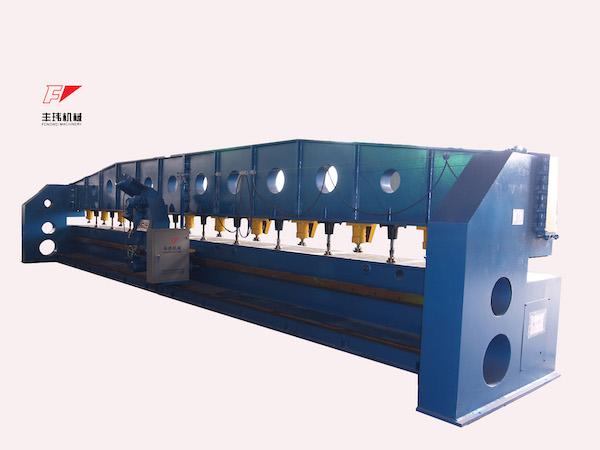

Edge milling machine

The edge milling machine is a kind of welding auxiliary equipment that adopts the high-speed milling of the cutter head. It is specially used for welding the steel plate before welding the steel plate.

The edge milling machine is a kind of welding auxiliary equipment that adopts the high-speed milling of the cutter head. It is specially used for welding the steel plate before welding the steel plate.

The edge milling machine is a kind of welding auxiliary equipment that adopts the high-speed milling of the cutter head. It is specially used for welding the steel plate before welding the steel plate. Edge milling machines, etc. Widely used in boiler, pressure vessel manufacturing industry, shipbuilding, electric power, petroleum, chemical machinery, construction machinery manufacturing, can process all kinds of medium and low carbon steel plate, stainless steel plate and aluminum plate before welding bevel, straight edge, U-shaped groove Wait.

The edge milling machine uses the working principle of milling to perform groove processing on metal materials such as carbon steel, high manganese steel, aluminum alloy, stainless steel, and copper before welding.

Edge milling machines are widely used in pressure vessels, steel structures and other industries that require high-quality milling effects. The thickness of the clamping steel plate is between 6-40mm, and the angle can be adjusted arbitrarily between 15°-50°.

Fengwei edge milling machine VS traditional edge milling machine

1. Low procurement cost;

2. Small footprint;

3. Simple operation and fast processing speed;

4. The length of the processed sheet is not limited.

5. Wear-resistant treatment, stress relief treatment, anti-corrosion treatment, etc.

No matter what kind of machinery is used, it is necessary to pay attention to personal safety and operate in accordance with the operation requirements. And understand the contents of the manual before operation to ensure familiarity with the machine. Edge milling machines are widely used in the production of spiral welded pipes with their significant advantages. Compared with the disc shear, the edge milling machine improves the processing quality of the plate edge, makes the forming and welding process more stable, reduces the consumption of the plate, and improves the production safety. However, the edge milling process also has inherent shortcomings. If the control is not good, it will lead to a series of forming and welding defects, such as pores, slag inclusions, incomplete penetration, burning collapse, welding deviation, and irregular welding beads. Let's talk about some problems that should be paid attention to when operating the edge milling machine.

First of all, the milling process is reasonably selected according to the actual production situation. Under the condition of guaranteeing production, try to adopt single edge milling process and choose type I groove, so as to reduce edge milling defects and make it easy to process. Select the appropriate working width, generally choose the milling amount of 8-10mm. That is, the working width of milling = the narrowest actual original plate width - 8mm.

Secondly, under certain circumstances, the milling machine can be flexibly adjusted to suit different situations. For example, when the deviation of the working width of the steel plate is 1-3mm, the forming quality is generally not affected; when the edge of the steel plate deviates from the delivery line by 1-3mm, it can basically be controlled. Therefore, when the steel plate is about to be de-milled out of control, it can be controlled by fine-tuning the headstock. There is another situation: if the width of some steel coils is not too large, the amount of blade milling can be reduced by fine-tuning the working width of the edge milling machine to ensure its service life.

The edge milling machine must be regularly lubricated and maintained to ensure the integrity and stability of the equipment. Coated blades with better wear resistance and better heat dissipation must be selected and replaced in time and regularly. It should be noted that the milling cutter disc pursues the overall effect. If only some of the blades are replaced, it will cause "metal wire" defects and increase the working strength of other blades. Therefore, all the blades must be replaced when changing tools. Otherwise, it may cost more.