Edge Milling Machines

Fengwei is a professional manufacturer and supplier of edge milling machines. The edge milling machines we produce are very popular in welding operations, and the welding edge milling machine itself is also relatively common.

Fengwei is a professional manufacturer and supplier of edge milling machines. The edge milling machines we produce are very popular in welding operations, and the welding edge milling machine itself is also relatively common.

Fengwei is a professional manufacturer and supplier of edge milling machines. The edge milling machines we produce are very popular in welding operations, and the welding edge milling machine itself is also relatively common. Welding edge milling machines are also a type of milling machine. To improve the use efficiency of the industry, edge milling machines with different functions are designed for different industries or jobs, such as cnc edge milling machines, large edge milling machines, and small portable edge milling machines.

Fengwei is a professional manufacturer and supplier of edge milling machines. The edge milling machines we produce are very popular in welding operations, and the welding edge milling machine itself is also relatively common. Welding edge milling machines are also a type of milling machine. To improve the use efficiency of the industry, edge milling machines with different functions are designed for different industries or jobs, such as cnc edge milling machines, large edge milling machines, and small portable edge milling machines.

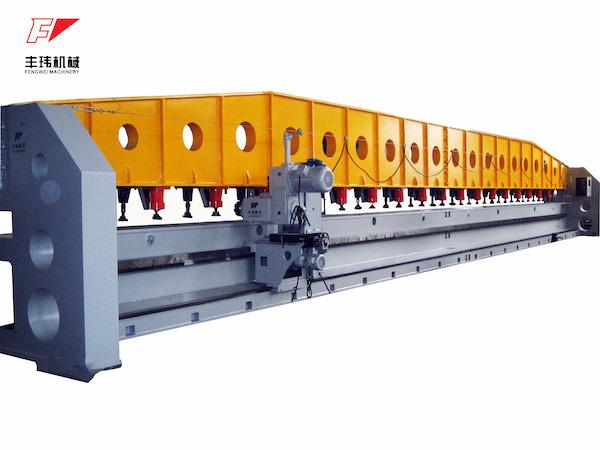

CNC milling machine

The cnc edge milling machine uses hydraulic means to fix the steel plate. Its milling power spindle has the functions of automatic rotation angle and self-stopping material. If you control the panel, you only need to input a few key parameters to automatically bevel edge milling. 0 to 80 degrees or so. Large groove depth can be automatically cut in layers, which is more suitable for automatic grooves of short and medium plates. This type of cnc milling machine has become the standard equipment of most welding and manufacturing factories abroad. The advantages of a cnc milling machine are a high degree of automation, simple operation, accurate groove precision, high production efficiency, and safety.

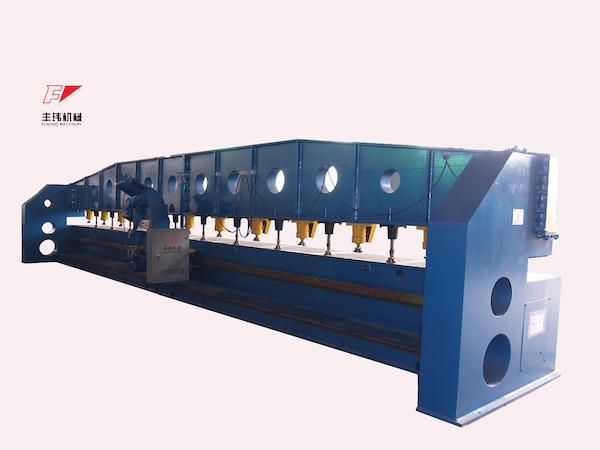

Large edge milling machine

Generally, large-scale edge milling machines use hydraulic cylinders to press and fix the workpiece on the worktable and then adjust the angle of the milling head and the stroke of the y and z axes to control the angle and depth of the steel plate groove. This type of model is more suitable for milling and beveling long plates. Generally, the machine can process plates with a length of 6-16 meters, and the dual powerheads can operate up and down beveling at the same time. The advantages of large edge milling machines are that the milling stroke is long and the spindle milling force is strong, so it is more suitable for the bevel of long and thick plates.

Small portable edge milling machine

Various portable small edge milling machines modified with electric or pneumatic tools can be beveling plates with small workloads or curved types.

As a substitute for an edge planing machine, the edge milling machine has the advantages of high efficiency, high precision, and low energy consumption. Compared with the traditional edge milling machine, its guide rail installation form is detachable, and through heat treatment, the bed structure is reasonable, the milling head runs more smoothly and reliably, the feeding system and the return system are completely independent, and the return speed is fast and efficient. . The angle of the milling cutter head is easy to adjust, and the custom cutter head is interchangeable with the standard cutter head. It is a replacement product for the traditional edge milling machine.

The performance and advantages of edge milling machine:

l Unique driving function;

l The special device stabilizes the machining accuracy;

l Special cutting of various metal materials;

l Advanced cutting tools and long-term supply of different blades.

Key steps and precautions in operation

l The no-load test of the main drive and the lift drive shall be performed alternately in an intermittent manner;

l Only after the no-load test machine is normal, the load test machine can be carried out;

l The machine must be in good lubrication conditions before it can enter normal operation;

l During the loading and load operation, the transmission system should be stable, without impact and abnormal noise;

l The working system and operating system should be flexible, accurate, and reliable, the rollers should not swing, and the temperature of each bearing should not exceed 80℃;

l The working mechanism and operating mechanism of the machine should be coordinated with each other, and the operation should be flexible, without abnormal noise or stuck phenomenon;

l During the use process, the oil supply of each lubricating point should be checked frequently to ensure that the oil supply of each lubricating point is sufficient;

l If abnormal noise, shock, vibration, or oil leakage is found, it should be stopped immediately for inspection, and normal operation can only be resumed after the abnormality is eliminated;

l In the process of use, all transmission mechanisms and connecting parts should be checked frequently to keep them free of looseness and damage;

l You must concentrate at work and pay attention to (check, watch, listen) the operation of the equipment at any time.