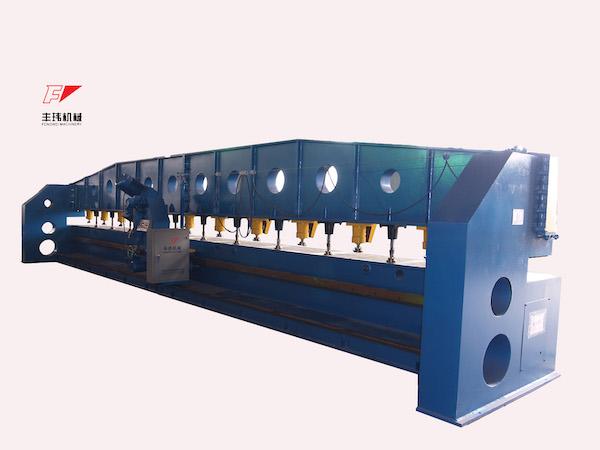

Edge milling machine

Edge milling machine is an advanced and efficient edge milling equipment, which promotes a new process of replacing planing with milling.

- cheap price

- low energy consumption

- high smoothness

Edge milling machine is an advanced and efficient edge milling equipment, which promotes a new process of replacing planing with milling.

Edge milling machine is an advanced and efficient edge milling equipment, which promotes a new process of replacing planing with milling. Edge milling machines are widely used in equipment manufacturing in pressure vessels, boiler, shipbuilding, electric power, chemical, and mechanical industries for straight edge and bevel breaking before welding sheets. The use of this equipment will provide convenient supporting services for users in environmental protection, automobile, shipbuilding, and other industries, and reduce the procurement cost of end customers.

The bed of the edge milling machine is welded with steel plates, with advanced design, reasonable layout, firm structure, strong rigidity, small deformation after internal stress treatment, and stable operation. To facilitate the positioning and machining of the workpiece, each part of the machine tool is equipped with two fixing brackets on the side of the guide rail. The guide rail is made of high-quality carbon steel. After the overall quenching and tempering, it is firstly planned and formed. The surface is quenched and finely ground and then fixed on the bed to ensure that the guide rail has good wear resistance and is not easy to deform. The headstock adopts the standard milling power head professionally manufactured by the machine tool factory. It is one-piece cast iron. The transmission components are mounted in the case. The AC motor drives the spindle to rotate. Spindle speed can be changed by changing gears. The speed range is 80-400rpm and can be adjusted. The spindle box is installed on the lifting slide of the column and can be lifted and lowered with the slide of the column. Press the headstock motor for normal milling.

The spindle of the edge milling machine is mounted on the slide. By rotating the worm shaft on the sliding plate, the headstock can be inclined 0-45° to the horizontal plane. The milling cutter head is installed at the end of the spindle, which can change different tools according to different milling conditions. A complete set of shifting gears in the feed box. The feed box is installed in the lower part of the large chute, and an extension gear is installed on the long rack of the guide rail. The feed motor drives the large chute at milling speed. The feed rate of the feed box is controlled by a two-speed motor. The feed rate is 0.2-0.6 M/min. When the speed changes, simply press the desired feed speed button. The feeding box is equipped with a fast return motor, and the return speed is 1.2m/min. The hydraulic control system is installed in the two large rooms on the right side of the bed and the inner bedroom. The lower part is used as the oil storage tank, and the upper part is equipped with hydraulic components, an oil pump, and a motor.

Compared with other similar products, it has the following advantages in performance and structure:

1. The main body base is welded. High-temperature tempering and stress relief treatment after welding to avoid deformation,

2. The guide rail adopts a combination of suspension type and seat type, which greatly improves the stability and reduces the vibration phenomenon in the process.

3. Conventional milling and guide rails are welded to the bed for post-processing. Since the bed must be annealed, the surface of the guide rail is relatively soft, which affects the service life of the whole machine. The guide rails of our factory are made of high-quality 45# steel, forged, rough planed, and tempered. After finishing, quenching, and fine grinding, it is screwed to the bed.

4. The feeding mechanism of the machine is driven by a variable frequency motor

5. The milling cutter head of the power head can use the standard milling cutter head.

6. This machine is equipped with a material blocking mechanism, which makes the positioning of the steel plate quick and convenient and improves work efficiency.

7. The end beam of the machine tool is provided with a throat, which can extend to one side when milling super-long workpieces.

8. The wiring of the whole machine is changed from the traditional hanging line to the safety sliding contact line, which is safe and beautiful.

Edge milling machine is an advanced and efficient edge milling equipment, which promotes a new process of replacing planing with milling.

The edge milling machine produced by Fengwei has been widely used in the production of spiral welded pipes with its significant advantages.

Edge Milling MachineDuring the use of the edge milling machine, the connection and maintenance of the various components after the installation has always been a headache for the welder.

edge milling machineFengwei is a professional manufacturer and supplier of edge milling machines. The edge milling machines we produce are very popular in welding operations, and the welding edge milling machine itself is also relatively common.

Edge Milling MachinesThe edge milling machine is a kind of welding auxiliary equipment that adopts the high-speed milling of the cutter head. It is specially used for welding the steel plate before welding the steel plate.

edge milling machineThe edge milling machine is a kind of welding auxiliary equipment that adopts the high-speed milling of the cutter head. It is specially used for welding the steel plate before welding the steel plate.

Edge milling machineThe edge milling machine is divided into XB series edge milling machine and self-driven edge milling machine.The edge milling machine produced by FENGWEI is widely used in boiler, pressure vessel manufacturing industry, shipbuilding, electric power, petro

Edge Milling MachineThe edge milling machine is a kind of welding auxiliary equipment that adopts the high-speed milling of the cutter head. It is specially used for welding the steel plate before welding the steel plate Edge milling machines, etc.

Edge milling machine