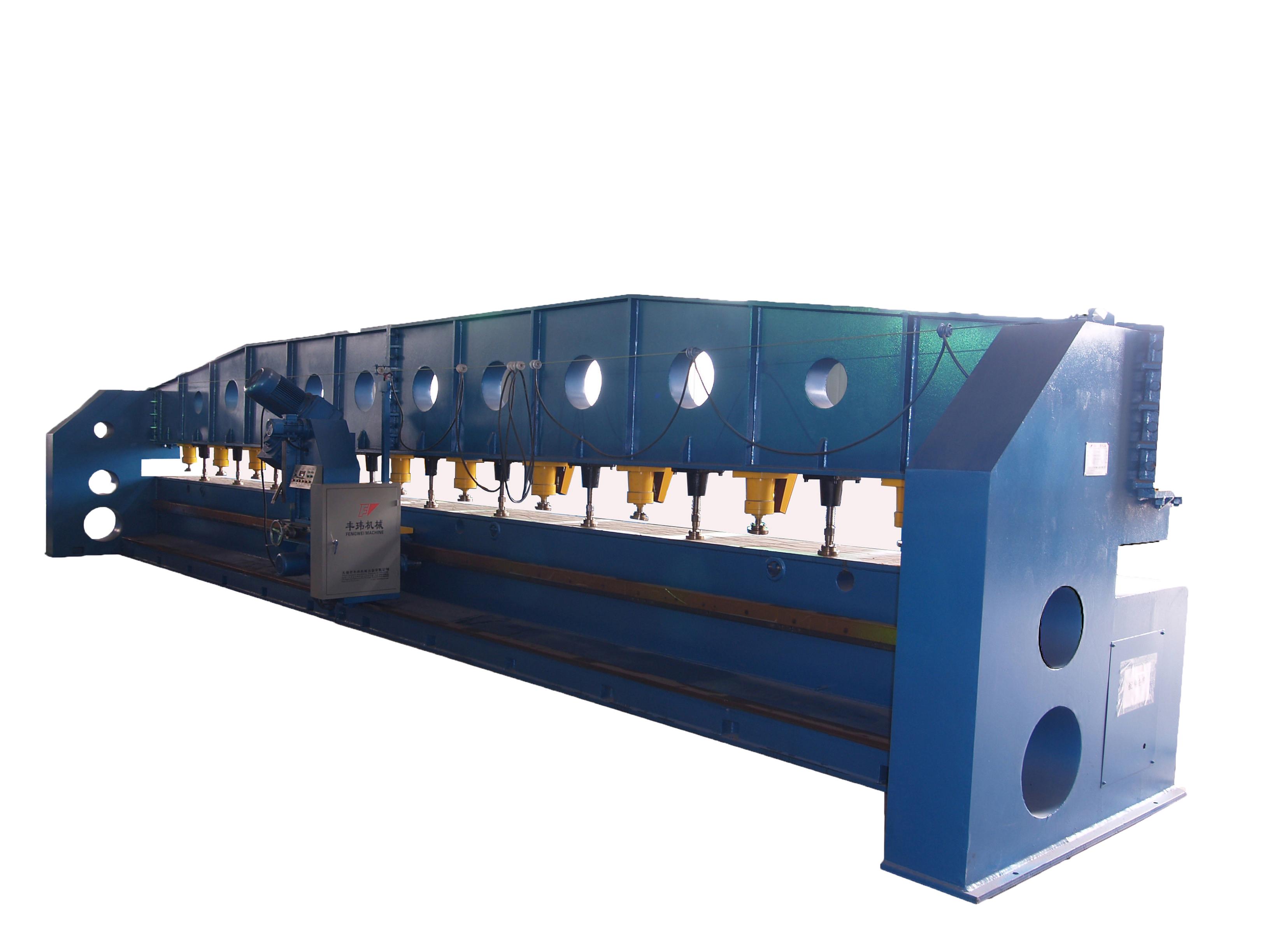

The edge milling machine is a kind of welding auxiliary equipment that adopts the high-speed milling of the cutter head. It is specially used for welding the steel plate before welding the steel plate Edge milling machines, etc.

Edge milling machines are widely used in heating furnaces, high-pressure container manufacturing, shipbuilding, electric power engineering, crude oil, machinery manufacturing, and engineering project machinery and equipment manufacturing. The welding seam production and processing, arc, straight edge, and U-shaped welding seam can be cut and formed at one time. Compared with the edge planer, it has the advantages of low price, low energy consumption, high efficiency, high smoothness, and convenient operation and maintenance.

The edge milling machine can be installed with slide rails in the whole process of installation. In application, it can be reasonably based on its heat treatment process and the reasonable configuration of the bed. The operation of the cutting head is more stable and reliable. The return system software in the machine equipment and The cutting system software is completely independent.

The return speed of the edge milling machine is faster, and the efficiency is relatively high in the whole process of application. The viewing angle of the milling cutter head in the machine is easy to adjust, and the standard spindle and its customized spindle can be exchanged. , Edge milling machine as a substitute for edge planer.

The edge milling machine has low energy consumption and high precision in the application, and the machine equipment is highly efficient in the whole process of application. In the fit, generally 5-40mm thin and thick, 15-50 degrees can be adjusted at will. The edge milling machine itself occupies a small area, the whole process of actual operation is very simple, and the production and processing rate of the machinery and equipment is relatively fast. Its length is limited. Before the actual operation of the edge milling machine, the oil level of the automobile oil tank in the hydraulic case of the main shaft bearing box and gearbox must not be less than its baseline. Reasonably check whether the cable connection is timely and whether the rotation of the motor is appropriate.

Maintenance of edge milling machine

1. Oil needs to be supplied during the operation of the edge milling machine. Before each shift, appropriate and clean mechanical lubricating oil is introduced into each pressure drop oil cup, and the hand-operated wheel is rotated forward and reversed to make it fully lubricated.

2. After 20-30 days of the normal operation of the CNC lathe, the oil plugs on the lower tool box and the spindle bearing box should be opened, and the box cover should be opened with gasoline heated up to 80 ℃, and the oil-stained iron pins in the box should be cleaned and tidy, re-enter the new oil to the vernier, and then it needs to be cleaned and oiled once every six months. High-precision edge milling machine

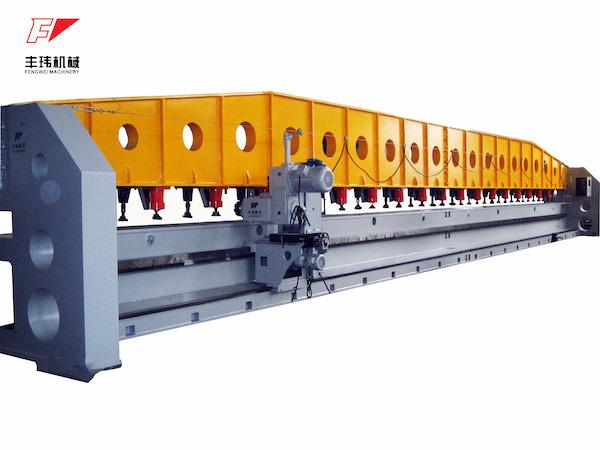

The edge milling machine is a kind of welding auxiliary equipment that adopts the high-speed milling of the cutter head. It is specially used for welding the steel plate before welding the steel plate. Edge milling machines, etc.

Edge milling machines are widely used in heating furnaces, high-pressure container manufacturing, shipbuilding, electric power engineering, crude oil, machinery manufacturing, and engineering project machinery and equipment manufacturing. The welding seam production and processing, arc, straight edge, and U-shaped welding seam can be cut and formed at one time. Compared with the edge planer, it has the advantages of low price, low energy consumption, high efficiency, high smoothness, and convenient operation and maintenance.

The edge milling machine can be installed with slide rails in the whole process of installation. In application, it can be reasonably based on its heat treatment process and the reasonable configuration of the bed. The operation of the cutting head is more stable and reliable. The return system software in the machine equipment and The cutting system software is completely independent.

The return speed of the edge milling machine is faster, and the efficiency is relatively high in the whole process of application. The viewing angle of the milling cutter head in the machine is easy to adjust, and the standard spindle and its customized spindle can be exchanged. , Edge milling machine as a substitute for edge planer.

The edge milling machine has low energy consumption and high precision in the application, and the machine equipment is highly efficient in the whole process of application. In the fit, generally 5-40mm thin and thick, 15-50 degrees can be adjusted at will. The edge milling machine itself occupies a small area, the whole process of actual operation is very simple, and the production and processing rate of the machinery and equipment is relatively fast. Its length is limited. Before the actual operation of the edge milling machine, the oil level of the automobile oil tank in the hydraulic case of the main shaft bearing box and gearbox must not be less than its baseline. Reasonably check whether the cable connection is timely and whether the rotation of the motor is appropriate.