welding positioner for sale - Wind Tower Production Line

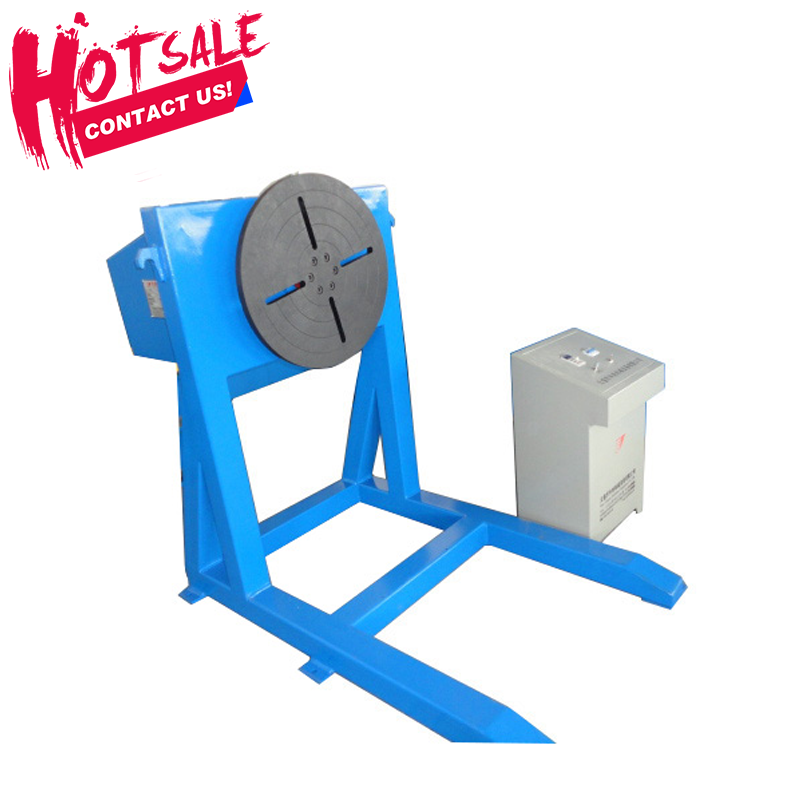

The welding positioner can be installed in any configuration. It allows controlled rotation of huge welded parts, structures or assemblies, providing the welder or operator with the optimum welding angle or allowing various operations to be performed in one session.

-

Loading Capacity (kg)

20 - 20,000 above

-

Rotation Speed (rpm)

0.2-2 (per request)

-

Overturning Speed (rpm)

0 - 1.1 (per request)

Welding positioners are used by welders, welding equipment dealers and manufacturers to position and move products to be welded.

- Improved welding efficiency and melting costs

- Superior weld quality, reduced errors and rejects.

- Reduces the number of semi-finished parts in the shop

- Allows to meet welding specifications more than once.

- Reduces operator fatigue

- Reduces welding on the floor

- Allows for robotic welding

- Improves safety

- Eliminates the need to move to access the weld bead when welding large components.

- Eliminates vertical and overhead welding

The axis of the welding positioner is often horizontal and can also be tilted horizontally so that half of the center of gravity rests on the device. If the mass is sufficient and the halves are long enough, a tailstock trunnion or roller assembly should be added to assist the weld at an end point other than the positioner and assist the halves safely. The center of gravity and lever arm (design torque) will change as the members are welded together. Therefore, the practicalities must be fully considered and the work must be done in conjunction with a qualified company.

Welding positioners are capable of holding the weld with special devices, and facilitate the installation and adjustment of the elements to create a safe and reliable welding installation. Cartridge holders and retainers are adapted and designed to accommodate the thermal expansion that occurs during welding. When sizing the weld positioning system, inertia must be considered, not only in terms of weight and overhang torque, but also in terms of the load on the fixture, in order to effectively implement the system and achieve the desired service life.

Automation of welding positioners

Welding positioners can also be used manually, usually controlled by a foot pedal, to move the welding material along the desired path and at the desired speed.

Semi-Automatic Welding Positioners

In semi-automatic welding, the weld positioner can be combined with other tools to improve productivity and throughput. The combination of positioner and torch holder allows semi-automatic welding by passing half of the weld under the torch, which is locked by the positioner. The fixed gun can be equipped with a welding head swivel to bridge large welding angles. This guarantees a constant speed and position as well as a high degree of repeatability.

Automatic welding positioner

Automatic welding stations can be used in conjunction with rotary welding positioner and robots to efficiently produce large welds with high accuracy and repeatability. Robotics can be used to certify automated welding processes and produce large parts.

Function and selection of welding positioners

Welding positioners are used in many manufacturing processes, most commonly for turning parts for welding and joining. Welding positioners are used in all industries, including aerospace, automotive, development and rail, metal and pipe fabrication, development, live vessel manufacturing and equipment manufacturing.

A wide range of options are available, including special coatings and custom paint colors, center guards, housing widths, smooth motion, oscillating motion, versatile motion modes, indexing and dwell time, and advanced cam rollers for increased static torque and custom servo motors.

Welding positioners can be manufactured as single or multiple axis machines. Single-axis machines can be supplied as a single machine for targets with small overhangs, or as trunnions with headstock and tailstock for longer targets or larger overhangs. Trunnion weld positioners are often equipped with an integrated control system.

Multi-axis welding positioners can significantly increase productivity and allow for the production of more complex parts. For example, an I-beam system can be mounted on a turntable, allowing the operator to load the other half while it rotates for welding.

Positioner for turntable biaxial welding

Options for welding positioners typically include

- Special spaces for headstock and tailstock mounting plates.

- Operating modes: clockwise, counterclockwise indexing and oscillation.

- Complete sessions with headstock, tailstock and base can be ordered.

- Completely different speed ratios

- Can be equipped with a servo motor and pointer supplied by the customer.

- Self-guided mechanical device

- Safety stop unit for maintenance and replacement of tools and fixtures

- Number of encoders or positioning units

- Contact rings

- Rotating unions

- Rules for choosing a welding positioner and a welding positioner manufacturer

In fact, price is the decisive factor when it comes to any automation tool. Your rotary welding positioner turntable partner should be able to offer very high accuracy, low backlash and zero backlash at an aggressive price. The ability to purchase the full range of trunnion options, including heavy duty bases, column bases, clamping devices and custom lengths, is often an advantage.

A high-precision, backlash-free, cam-operated rotary indexing table in a vertical position with a mounting plate on top is the ideal fixture for clamping headstock and tailstock welds. Huge volumes can be transported in smaller models, maximizing productivity and reducing initial costs. If necessary, the machine must be painted with special anti-corrosion coatings and its surfaces must be completely sealed to prevent intruders from entering.

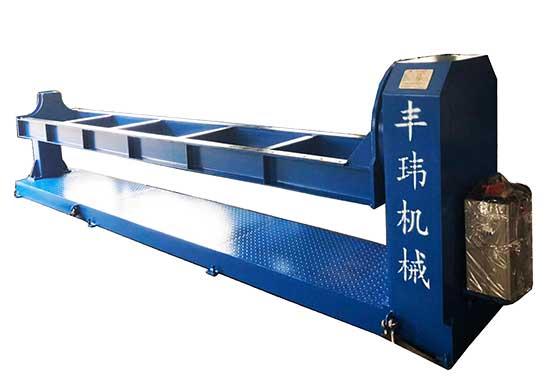

Benchtop Positioners have huge through holes for attaching pipes to tools and fixtures, and are designed in a conventional style to allow easy access to all components, such as pipes and wires, and to quickly start the design process.

The rotary welding table can be equipped with individual controls and pre-programmed panels to create a more versatile automation system, and can also be combined with a robot for increased productivity. A choice of robot manufacturers is desirable in your application. The freedom to choose your robot manufacturer allows the method integrator to adapt to the needs of the potential customer and minimize the price of the job design.

Check with the manufacturer of your welding positioner.

- Available for all manufacturers of servo motors and robot motors

- Ability to work with conventional single or three stage AC motors.

- Tailstock (multi-functional or clamp index drive, with or without drive motor, servo or AC)

- Tailstock (meets with or through bearing housing)

- Custom column and core frames

- Motorized drive without forced steering

- Micarta insulation kit for special welding applications

- Headstock and tailstock mounting flanges in black oxide

Manufacturers of the ideal tube welding positioner offer options to extend the life of the machine and reduce operating and maintenance costs. Here are some examples

- Hardened cams in the frame

- Large track cams in permanent contact with the cam

- Programmable rotation movement of each base and rotation angle of the double cams

- The central protection is mounted on each side of each cam.

- Total repairability, all parts can be repaired in the factory.

- Very low cost of parts maintenance

Welded headstock and tailstock positioning process

Options and component selection

Conventional double headstock and double Head and tailstock welding positioner fully utilize a high precision (< 1 second) planetary gearing system that is vertically mounted with mounting plates. Tailstock trunnions are ideal for carrying a large number of small models and minimizing the space occupied by tools on the floor. All trunnion models can be ordered with a custom or custom frame, with perfectly matched headstock and tailstock aids and one-piece base welds.

Automatic welding center

-

Maintenance and technical requirements for welding manipulators

The welding manipulator can be combined with the automatic welding machine to form "automatic welding mechanical equipment". And it can also be used in conjunction with welding rotators and welding positioners.

welding manipulators -

Fengwei Welding Positioner|Quality Inspection Method

The use of welding positioners has been despised from the beginning, but with the diversification of welding workpieces, welding positioners have begun to get With everyone's attention, welding equipment manufacturers have also begun to continuously upgra

welding positioner -

How to buy welding positioner?

Welding positioners are important auxiliary equipment to assist in welding and are often used in conjunction with welding manipulators and welding robots.

Welding positioners -

Best selling welding positioner

Fengwei has more than 20 years of experience in the manufacture and design of welding positioners. The basic shapes of our commonly used welding positioners include outrigger type, tipping rotary type, and double-column single-rotation type.

welding positioner -

How to judge the quality of welding positioner

The development of domestic welding positioners in China has been quite mature and perfect. o is the structure of the welding positioner we purchased reasonably?

welding positioner -

Choice of Welding Positioner|Welding turntable manufacturer from China

The basic shapes of commonly used welding positioners are outrigger type, tipping rotary type, and double column single rotary type.

welding positioners